Two Biomass Pellet Production Line With Twelve Pellet Mills

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Capacity | 0.8-4T |

| Pellets Diameter | 6Mm/8Mm |

| Pellets Length | 33Mm |

| Power | Variable |

| Motors | Multiple |

| Features | High Capacity, Fully Automated, Versatile Feedstock, High-Quality Pellets, Easy Operation, Durable Design, Cost-Effective |

Product Overview

Key Features

The Advantages:

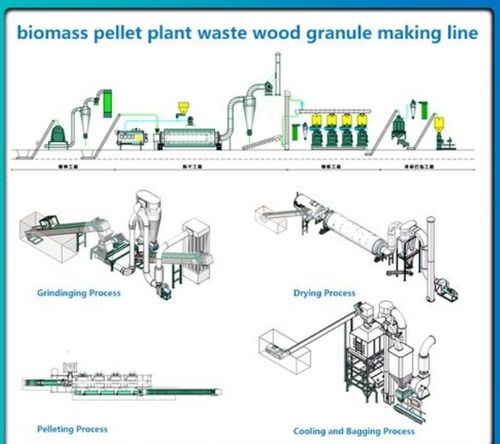

1. The production line includes wood crushing (if the raw material is not already granulated), material sieving, drying (if the raw material contains too much moisture), pelletizing, cooling, screening and packing. The whole pelletizing process can be highly automatically controlled and customized.

2. This is whole system automatic production line with different capacity demand and raw materials information.

3. The production line could suitable for raw materials like: rice husk, sawdust, rice straw, cotton stalks,peanut straw, grape straw, dry hay, grass, forest wood logs, forest wood branch, forest wood waste, wood waste, etc. Kinds of biomass waste.

4. High density, smooth surface, 6mm diameter or 8mm diameter, 33mm (20-50mm adjustable)length pellets you will get.

Raw material of biomass burning pellet:

Nearly all forestry and agro-waste material can be made into wood pellets by our ring die wood pellet mill, such as: Wood Chips, Shaving, Sawdust, Groundnut-shell, Sugarcane, Caster Shells/Stalk, Coffee Husk, Paddy Straw, Sunflower

Stalk, Cotton Stalks, Mustard Stalk, Jute Waste, Bamboo Dust, Tea Waste, Wheat Straw, Palm husk, Soybeans Husk, Coir Pitch Barks/Straws, Rice Husks etc. The final pellets can be used for industrial boilers and large power plants as well as home heating.

The complete wood pellet production line including the follow sections:

The wood sawdust making sectioni

--For cutting the log wood or wood branches into sawdust directly the drying section, for drying the wet materials into good moisture content about 15%

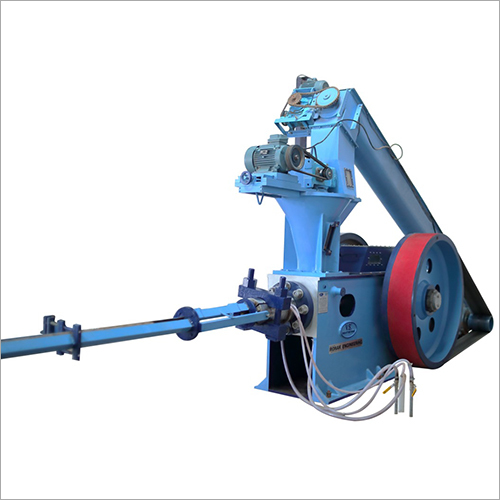

The pellet making sectioni

--This is the mainly part of this wood pellet production line, good for press 100% sawdust powder or any other kind of biomass materials into good quality pellets.

The cooling and screening sectioni

--For cooling the pellets and separate the dust and broken pellets,made the output pellets is good for storage.

The packing sectioni

--For packing the final produces into bags, normally can be 15-50kg/bags.

The control sectioni

--For different control cabinet and control system to control all the equipment, with overload protection system and also with motor protection system inside the control cabinet.

Detail quotation solutions for you, we need to know information as follows:

(1). What capacity would your prefer?

-----The Capacity Range of Wood Pellet Machine: 0.8-1T; 1.5-2T; 2-3T; 3-4T.

(2). What is your raw material?

-----According to different raw material (such as hard wood, soft wood, straw, rice hust), capacity is different.

(3). What is your raw material size?

-----Best size for pressing high quality pellets is 3mm-5mm.

(4). What is the moisture of your raw material?

-----Better to be 10-15%. ( If large than this, then we will recommend your Dryer Machine)

(5).Final Pellets Size?

-----We have Diameter for Pellets: 6mm, 8mm, 10mm, 12mm, (Different Diameters for your Different Requirement.)

------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm,between 30-36mm)

Our Company

Jiangsu Liangyou International Mechanical Engineering Co., Ltd is affiliated to Jiangsu Liangyou Agro Machinery Co., Ltd which has about 20 years of experience in the comprehensive development and utilization in agriculture field. It covers an area of 15000 square meters, locating in the zhongguancun science &technology industrial park in Liyang City, JiangSu Province, PRC.

FDSP has sold Feed machinery and fertilizer machinery throughout China and exported to Korea, South Africa, Russia, Thailand, Taiwan, Philippines, Malaysia, Australia, Egypt, Syria, Nigeria, Ethiopia, India, Bangladesh, Pakistan, Iran etc.

Company Details

Focusing on a customer-centric approach, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2003

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Changzhou, Jiangsu

General Manager

Mr. Zhi Liang Chen

Address

#6 Chenyang Road, Jiangsu Zhongguancun Science And Technology Industrial Park, Liyang, Changzhou, Jiangsu, 213300, China

biomass plant in Changzhou

Report incorrect details