Thermo Mechanical Fatigue Test System Collar Type: V Neck

Price:

Get Latest Price

In Stock

Product Specifications

| Force Rating | 50-500 kN |

| Heating | Induction |

| Cooling | Compressed air |

| Temperature Range | 100-1000°C |

| Extensometer | 1 micron |

| Grips | Hydraulic |

| Control Channels | 16 |

| Usage | Aerospace & power generation testing; Simulates thermal cycling and mechanical fatigue. |

| Features | Precise control, High temperature, Fatigue testing, Aerospace ideal, Power generation |

Product Overview

Key Features

combined effects of thermal cycling and mechanical fatigue. These

systems are useful for testing specimens subjected to synchronized

heating, cooling and temperature compensated strain or force with

optional expansion to simultaneous torsion or internal pressurization.

These fully integrated test systems are available in the range of 50 to

500 kN force ratings and are ideally suited for aerospace and power

generation industries.

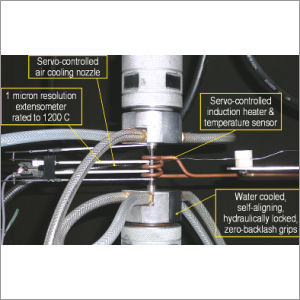

The specimen under test is subjected to

extreme temperatures followed by rapid cooling by means of a digitally

controlled induction heater and pneumatic air directed on the specimen

through air cooling nozzles.

Water cooled self locking and auto

aligning hydraulic grips, high temperature extensometer, temperature

sensors and load cell are typical components of the test system

controlled by a 2370 series controller with synchronized data

acquisition up to 5 kHz.

Standard features

- 50 to 500 kN force rating actuators

- High temperature extensometer

- Integrated digital servo controlled induction heating and pneumatic air cooling

- Self locking and water cooled hydraulic grips

- BiSS 2370 controller for synchronous control and data acquisition

- "Green" highly efficient hydraulic powerpack

Applications

- Axial low cycle fatigue

- Thermal cycling

- Thermo-mechanical cycling with independent phase control

- Optional axial torsion testing

- Optional axial torsion plus internal pressurization

- Optional axial/torsion/pressure/thermal cycling with phase control

Optional features

- Vaccum chamber housing specimen and grips

- Water chilling units with digital displays

- Spot welding units for thermocouple welding

- Optical pyrometers integrated with the system

Specifications

| Force rating | 50 to 500 kN |

| Heating | Induction 100 -1000 C |

| Cooling | Compressed air |

| Control channels | Axial, heating, cooling |

| Optional drives | Torsion and internal pressurization |

| Control scheme | Fully digital up to 16 channels, 2-5 kHZ |

| Waveforms | Arbitrary, user defined |

| Data acquisition | Up to 5 kHZ, synchronized |

Note: Dimensions subject to minor variations based on specific ratings.

Company Details

Focusing on a customer-centric approach, BANGALORE INTEGRATED SYSTEM SOLUTIONS (P) LTD has a pan-India presence and caters to a huge consumer base throughout the country. Get Testing & Measuring Equipment from BANGALORE INTEGRATED SYSTEM SOLUTIONS (P) LTD at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

45

Establishment

1992

Working Days

Monday To Sunday

GST NO

29AAACB5854G1ZL

Certification

S.S.I.

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29AAACB5854G1ZL

Bengaluru, Karnataka

Director

Mr. Venkatesh

Address

No.5, 302/4, Seetharam Industrial Estate, V.P. Road, Jalahalli Bengaluru, Karnataka, 560013, India

fatigue testing machine in Bengaluru

Report incorrect details