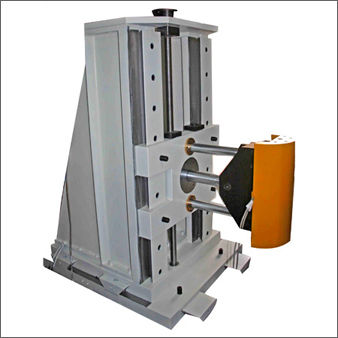

Multi Actuator Test System

Price:

Get Latest Price

In Stock

Product Specifications

| Actuator Control | Upto 8 |

| Data Channels | 60 analog |

| Power Consumption | 1.5 kVA |

| Cooling | Air-cooled |

| Connectors | MIL sockets |

| Usage | Actuator testing, structural testing, airframe component testing |

| Dimensions | Varies |

| Features | Mobile unit, Easy access, Quiet operation, Multi-actuator, Data acquisition, Safety interlocks |

Product Overview

Key Features

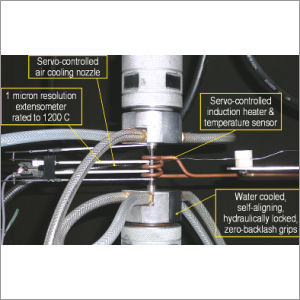

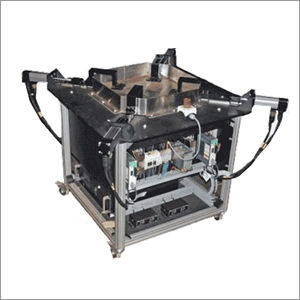

BiSS Multi Actuator Control System is capable of controlling upto 8 actuators. It is a fully integrated mobile unit with an air-cooled hydraulic powerpack. It provides ease of access to all system components and has simple and unambiguous external connectivity. This extremely quiet operating system facilitates mil sockets with pin out markings to connect force and stroke transducers. Easy actuator connections possible with the quick release sockets available. The servo controlled pump incorporates thermostatic cooling, variable rpm control of pump speed, actuator manifold with dump cutoff and servo valves, system pressure and temperature indicators, individual port pressure indicators and safety limit interlocks are other unique features of the system. The whole system is castor mounted and can be easily relocated. No external utilities are required for cooling.

The system is powered by a 2360 controller with 8 channels of load cell and LVDT signal conditioning and upto up to 60 channels of data acquisition with electronics that support strain gages, LVDTs and high level inputs. The integrated control and data acquisition system along with host PC with large size TFT panel display are housed in an air-conditioned enclosure that is part of the system chassis.

Specifications

- Control of upto 8 hydraulic actuators

- 60 channels of analog data acquisition

- Multi-channel, multi-station capability

- Safety limit interlocks with dump cut-off valves

- Nominal 1.5 kVA, peak 6 kVA power consumption.

- Fully integrated unit on wheels that can be relocated and reconnected for a new test in a matter of hours

- Contamination-insensitive servo-hydraulics

- Thermostatically air-cooled servo-controlled pump.

- MIL-sockets with pin-out markings to connect Force and Stroke transducers

- 2 x 8 quick-release sockets.

- System and 2 x 8 port pressure indicators,scribble / paste board

- Air-conditioned control cabinet.

- Compact mobile footprint, with unambiguous external connectivity

- Ready access to all system components

- Integrated oil-air heat exchanger with dual variable rpm blowers

- Actuator service manifolds overload protection settings,dump/cutoff and servo valves

- Large oil reservoir with submerged pump

- Variable rpm pump motor with forced cooling

- Pump servo control and heat-exchanger thermostatic control

- Oil pressure and temperature indicators

- Extremely quiet operation

- Power management through servo-controlled variable rpm control of pump speed

- Application software for static and pseudo-random structural testing

- Suitable for airframe component full-scale testing.

Company Details

Focusing on a customer-centric approach, BANGALORE INTEGRATED SYSTEM SOLUTIONS (P) LTD has a pan-India presence and caters to a huge consumer base throughout the country. Get Testing & Measuring Equipment from BANGALORE INTEGRATED SYSTEM SOLUTIONS (P) LTD at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

45

Establishment

1992

Working Days

Monday To Sunday

GST NO

29AAACB5854G1ZL

Certification

S.S.I.

Related Products

More Product From This seller

Seller Details

GST - 29AAACB5854G1ZL

Bengaluru, Karnataka

Director

Mr. Venkatesh

Address

No.5, 302/4, Seetharam Industrial Estate, V.P. Road, Jalahalli Bengaluru, Karnataka, 560013, India

Testing & Measuring Equipment in Bengaluru

Report incorrect details