Swivel Machinery(autostacking & Autocounting)

Price:

Get Latest Price

In Stock

Product Specifications

| Features | Faster Stretching, Accurate Printing, Optimum Tension, Perfect Stretching, Accurate Registration, Multiple Colors |

Product Overview

Key Features

Swivel Machinery (Autostacking & Autocounting)

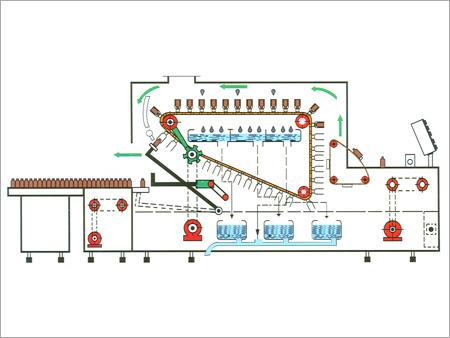

- Machine Construction is very robust with overall box type extruded heavy-duty structural frame and mounted on anti-vibration pad for smooth and noiseless running.

- Infinitely Controlled Platen Movement by High Precision Twin Eccentric powered by Servo Motor driven reduction Gear Box.

- It has an option to adjust the cutting height in micron level which enables good trim quality

- Use of Duplex sandwich heater arrangement allows even the thickest material to be heated with the minimum material stress to suit the product being formed and is also assisted by a multi heating zone controlled by PID with SSR Module.

- It has an option to adjust the heater trolley in height and width as per required web width as well as shape and size of the product.

- The accurate indexing of sheet (web) is done by spiky chain conveyor and driven by a servomotor.

- It has an option to control web length at mm difference with precise sheet indexing via microprocessor.

- A Servo Driven Plug Assist is provided in the machine to enhance the product quality and uniform wall thickness of formed products.

- A piecing heater is provided at the start of both side of chain for smooth conveying of the sheet through spiky chain.

- All other close controls of various stages are given by a particular comprehensive range of controls provided in the machine through Micro Processor / PLC.

- It is easy and has an operator friendly touch screen option.

- Accurate and micron positioning controls ensures high quality and optimum utilization.

- It has an Anti sagging arrangement provided on both sides of the chain conveyor to control the sag.

- It also has an option to run the machine at the Automatic Mode, after setting up manually and vice versa.

- It has an essence to save time resulting high productivity with micron accuracy.

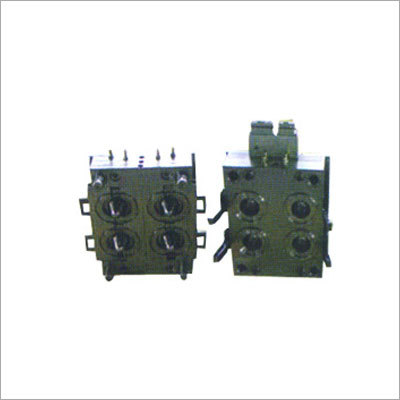

- Wider span twin support at Bottom Platen results zero bulging even for widest maximum mold.

- Highest operation cycles per minute achieved with clinical smoothness results in top quality forming.

- Trouble shooting points are visible in screen instantly.

- A Tilt Mould Technology has been adopted to Swivel the bottom part of the mould driven by Servo Motor and synchronized with Auto Stacker for smooth stacking of the formed products.

- An Automatic Stacking unit is coupled with the machine and aligned with bottom platen driven by Servo Motor for accurate staking.

- A Separator is provided at Auto-Stacking unit to separate a pre-fix required number of glasses/Cups from stacked products to achieve the uniform counting in each packet.

- Advance Technology Electrical/electronic system helps almost maintenance free machine.

- Auto Stacking prevents any human touch to finished products and improved Hygiene condition of the plant.

- Auto Staking facilitates lowering down of manpower requirement, which in turn creates a low cost of production.

- Auto Staking prevents the air throw ejection system and avoids any de-shaping of finished products.

- An Auto lubrication pump is provided in the machine for continuous lubrication of all brushes and bearings for smooth movement and avoid wear and tear of such components.

- Separate lubricators are provided at the entry point of spur guide for better and smooth movement of chain transmission and piercing of sheet.

Company Details

Focusing on a customer-centric approach, MLEW ENGINEERING PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Packaging Machine in bulk from MLEW ENGINEERING PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

24

Establishment

1984

Working Days

Monday To Sunday

Certification

ISO 9001:2008

Related Products

More Product From This seller

Seller Details

Kolkata, West Bengal

Executive Director

Mr. Niladri Das

Address

24/63, Nabalia Para Road, Behala, Chowrasta, Kolkata, West Bengal, 700008, India

Packaging Machine in Kolkata

Report incorrect details