Superbond By Sigma Waterproofing & Construction Chemicals

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Acrylic Copolymer |

| Mixing ratio | 2:1 |

| Application | Brush coating |

| Coverage | 20-25% |

| Toxicity | Non-toxic |

| Features | Strong bonding, Improved strength, Water resistance, UV resistant, Easy mixing, Durable coating, Fungus resistant |

Product Overview

Key Features

Product Description:

SUPERBOND is a single component 100% Acrylic Copolymer admixture specially developed to improve the properties of cementitious compositions. SUPERBOND when used in combination with standard quality of Ordinary Portland Cement (OPC), it enhances the mechanical properties such as bonding (adhesion) with various building materials, flexural, compression and impact strength. SUPERBOND improves the thin section fragility of cement when used as coating.

Features / Advantages:

SUPERBOND is easily mixed with cement, cures to a hard, tough, wear resistant surface & bonds (adheres) strongly to most of the building materials.

It can be overcoated by exterior emulsion coating or cement based paints.Can be applied to uniform thickness coating on horizontal and vertical surfaces.

It allows trapped water vapour to escape and prevents blistering and adhesion failure.

It makes cement mortar or coating compact, thus preventing salt penetration into concrete.

It is unaffected by UV light and prevents discolouration of concrete and corrosion in steel due to its alkali nature.

It is resistant to water, dilute acids & alkali solutions. Coating is highly durable even in continuous contact with water.

It is non-flammable, non-hazardous. Does not evolve toxic gases when exposed to fire. Non toxic to human being.

Most properties improve on ageing. Resistant to fungus and microorganism growth.

Areas of Applications:

Waterproofing of building terraces, toilet sunken portion basements, water tanks & swimming pools.

Bridge decks, runway, parking garages industrial floors, factory floors, balconies, mechanical rooms, side wall etc.

Pools & foundation, reservoirs, channel dams, water towers, tunnels etc.

sewers, silos, foundation walls, swimming pools etc.Repairing of concrete & masonary walls - Internal, External and terrace roofs by cement mortars.

Renovation & protection of concrete against corrosion and salt petre.

As an additive with cement paints which improves waterproofing property, coverage by 20-25% and life of cement paint?

As a bonding agent for old concrete to new concrete.

Surface Preparation :

Surface preparation is the most important step before application to get best results and to avoid failure.

1. The surface must be free from dust, coatings, loose particles, fungus, moss, oils,

greases and mould release agents.

2. Clean the surface by scrapping, sand blasting, grinding to remove dirt & loose particles.

3. Treat the surface with 5 to 10% Hydrochloric acid followed by complete neutralisation

with water which will improve bonding of the coating.

4. Oils,Greases and Mould release agents can be cleaned with solvents.

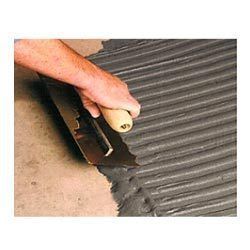

A. Brush coating application :

For waterproofing of terraces, toilet blocks, swimming pools, water tanks and basements.

1. After surface preparation, pre-wet the surface with sufficient water.

2. Allow the surface to dry minimum for 1 hour. Mix 2 Kgs. of Ordinary Portland Cement

with 1 ltr.of SUPERBOND homogenously till no lump or air bubble remains in the mix.

3. Apply coating by brush and allow it to dry for 2 hours before application of second coat.

Minimum 2 coats are required.

B. Cement paint application;

1. Mix 3-4 ltrs. of SUPERBOND with 50 Kgs. of Cement paint homogenously to form an

uniform mix.

2. Apply the mixed and diluted cement paint by brush.

3. Allow to dry for 2 hours before application of Second coat.

4. It increases the coverage of cement paint by 20-25%.

C. Patching mortar:

Voids (Holes) can be filled and levelled by using SUPERBOND mortar. Use 10% of SUPERBOND on cement weight.

Curing of SUPERBOND Coating & Mortars :

1. SUPERBOND coating should be protected from movements or traffic for at least 48 hrs

& should be kept moist for the next 24 hrs. by sprinkling of water or covering with wet

gunny bags. Continue the moist curing for at least 72 hrs. before ponding.

2. Curing must be continued for minimum 28 days before exposure to weather. Ponding

with water for 28 days itself is a water proofing test.

Storage & Shelf life:

Store the material in cool & dry place. Shelf life is 2 years from the Date of Manufacture when stored in original unopened container.

Cleaning of Tools & Equipments:

Tools & Equipments can be easily cleaned with water.

Packing: 25 lit, 50 lit, 100 lit, 200 lit.

Company Details

Focusing on a customer-centric approach, SIGMA WATERPROOFING & CONSTRUCTION CHEMICALS has a pan-India presence and caters to a huge consumer base throughout the country. Get Construction Chemicals from SIGMA WATERPROOFING & CONSTRUCTION CHEMICALS at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Establishment

2005

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Navi Mumbai, Maharashtra

Director

Mr. Manoj Shashikant Sharbidre

Address

No. 15, Tirupati Corner, Plot No. C-1,Sector-12 Kharghar, Navi Mumbai, Maharashtra, 410210, India

Construction Chemicals in Navi Mumbai

Report incorrect details