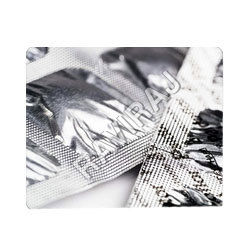

Strip Packing Foils

Price:

Get Latest Price

In Stock

Product Specifications

| Foil Material | Aluminium alloy AA 8011 |

| Foil Gauge | 0.025mm - 0.040mm |

| Sealant | Colourless LDPE |

| Polymer Gauge | 150-200 GSM |

| Peel Strength | 200 g/15 mm min |

| Seal Strength | 450 g/15 mm min |

| Reel Width | 45mm-900mm |

| Features | Lightweight, High quality, Chemical resistant, Moisture resistant, Pharmaceutical grade, Customizable printing, Secure sealing |

Product Overview

Key Features

We are one of the leading manufacturers, suppliers and exporters of a wide range of Strip Packing Foils. These foils are manufactured using high quality raw material, which is procured from authentic vendors of the market. It is highly appreciated in the market for its lightweight, high quality and resistance against chemicals and moisture. Strip Packing Foils are widely used for packing medicines, tablets, capsules and many more. We also check all the foils on various parameters to ensure flawlessness.

Other information:

Foil Material

Soft fully annealed aluminium alloy AA 8011 confirming to Aluminium Association specification.

| Std. Foil Gauge Options | Tolerance (+/- 8%) | Min. Bursting Strength |

| 0.025 mm | +/- 0.0020 mm | 1.5 kg/sq. cm |

| 0.030 mm | +/- 0.0024 mm | 1.9 kg/sq. cm |

| 0.040 mm | +/- 0.0032 mm | 2.5 kg/sq. cm |

Sealant

Colourless LDPE Confirming to the applicable Government regulations regarding direct contact with medicines and drugs.

| Standard Polymer Gauge Options | Nominal GSM | Tolerance (+/- 15%) GSM |

| 150 | 34.39 | +/- 5.17 |

| 180 | 41.27 | +/- 6.21 |

| 200 | 45.85 | +/- 6.90 |

Density of LDPE: 0.917 g/cc.

Peel Strength of Lamination: 200 g/15 mm min.

Seal Strength Betweent Top & Bottom Foil: 450 g/15 mm min.

Printing & Lacquer Coating

Printed as per text, layout and shade approved by customer. For non-printed specification, clear lacquer to be coated as a protective coating and good printability. Printing inks and lacquer coatings are capable to withstand 180 deg. C for 1 sec. dwell time.

Configuration

Printed and Unprinted Pharma Foils are available in the reel forms. Unprinted pharma foils are also available as Jumbo roll.

Winding Direction

Generally - printed or clear lacquer side is out in the finished reel.

Core

Material Options: (a) Plastic (b) Aluminium (c) Card board.

Core ID: 76 mm +/- 0.5mm.

The length of the core is equal to the width of the web.

Splices: Butt type made with 25mm pressure sensitive tape.

Reel Outer Diameter: 250 +/- 10 mm for slit material 400 +/- 10 mm for Jumbos.

Reel Wander: Within +/- 1 mm.

Reel/Web Width

Plain: 45mm to 900mm with a tolerance of +/- 0.5mm

Printed : 45mm to 600 mm with a tolerance of +/- 0.5 mm

Joints Per Reel: Maximum 2 Average less than 1.

Pin Holes: Nil.

Identifications

Each reel shall be identified with a sticker with Reel number, Specification, Net weight, Gross weight, Operator name & Date of manufacture.

Packing

Pharma foils are packed in cardboard carton.

Relevant markings are provided in each outer package.

Recommended Operating Conditions

| Sealing temperature | 130 to 150 deg. C |

| Sealing pressure | 2.8 to 5.6 Kg/sq. cm or 40 to 80 lbs/sq. inch |

| Dwell time | 0.25 to 0.5 sec. |

Covering Area of 1 Kg Finished Material (Nominal)

| Gauge & Temper of Foil | Covering area in Sq.mts/Kg with 150 Gauge polyethylene lamination |

| 0.025 (soft) | 9.78 |

| 0.03 (soft) | 8.64 |

| 0.04 (soft) | 7.00 |

Table Showing Thickness Tolerances of Foil

| Foil Gauge | Thickness (mm) | GSM | ||||

| Min. (-80%) | Nominal | Max. (+8%) | Min. (-8%) | Nominal | Max. (+8%) | |

| 0.025 mm | 0.023 | 0.025 | 0.027 | 62.33 | 67.75 | 73.17 |

| 0.030 mm | 0.028 | 0.030 | 0.032 | 74.80 | 81.30 | 87.80 |

| 0.040 mm | 0.037 | 0.040 | 0.043 | 99.73 | 108.4 | 117.07 |

Table Showing Thickness Tolerances of Polyethylene

| Poly Gauge | Thickness (mm) | GSM | ||||

| Min. (-10%) | Nominal | Max. (+10%) | Min. (-10%) | Nominal | Max. (+10%) | |

| 150 | 0.0338 | 0.0375 | 0.0413 | 29.22 | 34.39 | 39.56 |

| 180 | 0.0405 | 0.045 | 0.0495 | 35.06 | 41.27 | 47.48 |

| 200 | 0.045 | 0.05 | 0.055 | 38.95 | 45.85 | 52.75 |

Technical Specifications

| Density Of Ldpe | 0.917 g/cc |

| Peel Strength Of | 200 g/15 mm min. |

| Seal Strength Bet. Top & Bottom Foil: | 450 g/15 mm min. |

| Printing And Lacquer | Printed as per text, layout and approved by the Customer. For non-printed specification, clear Lacquer to be coated as a protective coating and good printability. Printing inks and lacquer coatings are capable to withstand 180 deg. C for 1 sec. dwell time. |

| Configuration: | Printed and Unprinted Pharma Foils are available in the reel forms. Unprinted pharma foils are also available as Jumbo roll. |

| Winding Direction: | Generally, printed or clear lacquer side is out in the finished reel. |

| Core: | Material options (a) Plastic (b) Aluminium (c) Card Board |

| Splices: | Butt type made with 25 mm pressure sensitive tape. |

| Reel Outer Diameter: | 250 +/- 10 mm for slit material. 400 +/- 10 for Jumbos. |

| Reel Wander: | Within +/- 1 mm |

| Reel/Web Width: | Plain : 45 mm to 800 mm with a tolerance of +/- 0.5 mm. |

| Joints Per Reel: | Maximum 2. Average less than 1. |

| Pin Holes: | Nil. |

Test Certificates

Test certificates giving the actual observed values of different parameters will accompany.

Company Details

Focusing on a customer-centric approach, RAVIRAJ FOILS LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Buy Aluminium & Foils in bulk from RAVIRAJ FOILS LIMITED at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

225

Establishment

1997

Working Days

Monday To Saturday

GST NO

24AAACR7333J1ZE

Certification

ISO-9002, COMPANY

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAACR7333J1ZE

Sanand, Gujarat

Sr. Manager - Exports

Mr. Kandarp Soni

Address

Survey No. 169, P.O. Chharodi, Sanand Viramgam Highway, Sanand, Gujarat, 382170, India

packaging strip in Sanand

Report incorrect details