Stainless Steel Rotary Kiln Tyre - Warranty: 2 Years

Price: 120000.00 INR / Unit

(120000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

-1+

Product Specifications

| Hardness | Yes |

| Application | Industrial use |

| Warranty | 2 years |

| FOB Port | Nhava Sheva Sea Port or nearby seaport area, as per clients requirements. |

| Payment Terms | Paypal, Telegraphic Transfer (T/T), Others, Letter of Credit (L/C) |

| Supply Ability | 10 Per Month |

| Delivery Time | 4 Week |

| Packaging Details | Packed in a seaworthy wooden case or according to buyersaEURtm request. |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | ISO 9001:2008 |

| Returnable | No |

| Price | 120000.00 INR (Approx.) |

| Stock Quantity | 5 |

| Packsize | 1 |

| Brand Name | PIYALI ENGINEERING CORPORATION |

| Moq | 1 |

| Price Type | fixed |

| Currency | INR |

| Mop | 1 |

| Unit Type | Unit/Units |

| Product Unit | 1 Unit/Units |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

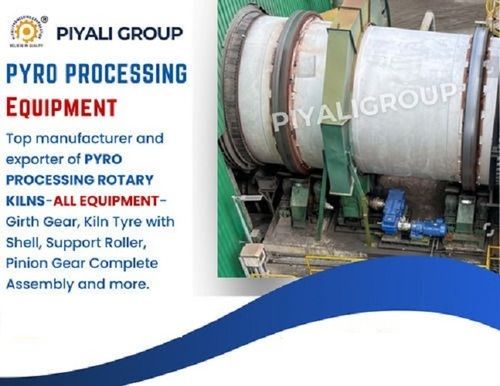

We are leading Manufacturers, Suppliers and Exporters of Rotary Kiln tyre Shells of Different Production sizes for DRI Sponge Iron Plants varies from 350 TPD, 50 TPD, 100 TPD, 175 TPD, 350 TPD and 500 TPD Both Conventional Kilns and Pre-Heating Kilns.

We are the manufacture and supply KILN PINION WITH SHAFT ASSEMBLY equipment, KILN PINION GEARS are customized according to production technology and capacity. We manufacture standard kiln rollers having combined sensible structural design with advanced isothermal small flow burner, monitored by expert engineers. We manufacturer durable and long-life kiln rollers, high quality refractory insulates materials we prepared in a special kiln wall structure to protect for the excellent insulation effect, surface heat outside kiln is below 60 degrees for low fuel consumption.

Material : IS 2708 Grade - II/ EN-19 Forged, EN-24 Forged as per client requirement.

Kiln Tyre, Kiln Tire, Rings Rollers, Rotary Cooler Tyre, Rotary Dryer Rigns, Path rings, Rings, Tyres, Cast Steel rings, Casting Tyres, Forging Tyres, seamless Forged rings roller for Steel Plant, sponge iron plant, Power Plant, Mineral and mining Industries , Sponge Iron Plant DRI Base, Cement Plant Kiln Riding Rings, Cement Plant Live Rings etc. for 50 TPD, 100 TPD, 200 TPD, 300 TPD, 350 TPD, 500 TPD, 600 TPD, 650 TPD, 900 TPD, 100 TPD, 1200 TPD Sponge Iron plant, Cement plant all capacity plants.

Used Applications : sponge Iron Plant, Sugar plant, cement plant, activated carbon plant, fertilizer plant, mineral plant, Material: Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel Standard: ISO, EN, DIN, AISI, ASTM, JIS, IS, GB

Fertilizer Granulator Dryer drum, cooler shell, kiln shell, Ball mill shell and griding mill dryer spares manufacturer and supplier in India. Ring Gear, Girth Gear, Pinion drive gear, Riding ring, Kiln Shell Tyre ring, thruster ring rollers etc.

Experienced Process: Forging/Casting Normalizing & Tempering-Proof Machining Quenching & Tempering Finish Machining (Teeth Grinding) We can offer you in various process conditions.

Main Export Markets: Asia, Australasia, Central/South America Eastern Europe Mid East/Africa North America Western Europe Global.

We are the manufacture and supply KILN PINION WITH SHAFT ASSEMBLY equipment, KILN PINION GEARS are customized according to production technology and capacity. We manufacture standard kiln rollers having combined sensible structural design with advanced isothermal small flow burner, monitored by expert engineers. We manufacturer durable and long-life kiln rollers, high quality refractory insulates materials we prepared in a special kiln wall structure to protect for the excellent insulation effect, surface heat outside kiln is below 60 degrees for low fuel consumption.

Material : IS 2708 Grade - II/ EN-19 Forged, EN-24 Forged as per client requirement.

Kiln Tyre, Kiln Tire, Rings Rollers, Rotary Cooler Tyre, Rotary Dryer Rigns, Path rings, Rings, Tyres, Cast Steel rings, Casting Tyres, Forging Tyres, seamless Forged rings roller for Steel Plant, sponge iron plant, Power Plant, Mineral and mining Industries , Sponge Iron Plant DRI Base, Cement Plant Kiln Riding Rings, Cement Plant Live Rings etc. for 50 TPD, 100 TPD, 200 TPD, 300 TPD, 350 TPD, 500 TPD, 600 TPD, 650 TPD, 900 TPD, 100 TPD, 1200 TPD Sponge Iron plant, Cement plant all capacity plants.

Used Applications : sponge Iron Plant, Sugar plant, cement plant, activated carbon plant, fertilizer plant, mineral plant, Material: Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel Standard: ISO, EN, DIN, AISI, ASTM, JIS, IS, GB

Fertilizer Granulator Dryer drum, cooler shell, kiln shell, Ball mill shell and griding mill dryer spares manufacturer and supplier in India. Ring Gear, Girth Gear, Pinion drive gear, Riding ring, Kiln Shell Tyre ring, thruster ring rollers etc.

Experienced Process: Forging/Casting Normalizing & Tempering-Proof Machining Quenching & Tempering Finish Machining (Teeth Grinding) We can offer you in various process conditions.

Main Export Markets: Asia, Australasia, Central/South America Eastern Europe Mid East/Africa North America Western Europe Global.

Company Details

Piyali Engineering Corporation, Established in 2016 at New Delhi in Delhi, is a leading Exporter,Manufacturer,Supplier,Fabricator of Tyres & Tubes in India. Piyali Engineering Corporation is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Stainless Steel Rotary Kiln Tyre, Piyali Engineering Corporation has made a reputed name for itself in the market with high-quality Cast Steel 350 TPD Kiln Tyre, Casting Kiln Tyre And Support Roller Of Lime Rotary Kiln Parts, High Design Kiln Tyres, etc.

Focusing on a customer-centric approach, Piyali Engineering Corporation has a pan-India presence and caters to a huge consumer base throughout the country. Buy Tyres & Tubes in bulk from Piyali Engineering Corporation at Trade India quality-assured products.

Focusing on a customer-centric approach, Piyali Engineering Corporation has a pan-India presence and caters to a huge consumer base throughout the country. Buy Tyres & Tubes in bulk from Piyali Engineering Corporation at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Fabricator

Employee Count

60

Establishment

2016

Working Days

Monday To Sunday

GST NO

07ASMPB1250H1Z3

Payment Mode

Others

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07ASMPB1250H1Z3

New Delhi, Delhi

Krishna Maurya

Address

Plot B2, KH NO- 1708, NEAR CBR CHOWK, AYA NAGAR, New Delhi, Delhi, 110047, India

Report incorrect details