Spray Dryer - High-efficiency Evaporation System For Converting Solutions Into Fine Powders | Custom Configurations, Advanced Drying Technology, Versatile Feed Compatibility

Price:

Get Latest Price

In Stock

Product Specifications

| Feed Type | Solution/Slurries |

| Drying Medium | Air |

| Material | Stainless Steel |

| Process | Atomized Stream |

| Configuration | Various |

| Application | Manufacturing |

| Technology | Spray Drying |

| Features | Powder Production, Drying Solutions, Customizable Design, Efficient Drying, Versatile Application |

Product Overview

Key Features

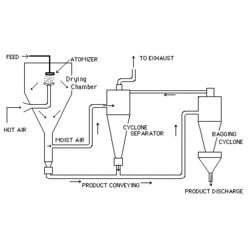

There is a wide variety of spray dryer configurations, each suited to a particular type of powder or feed consistency. Spray drying technology is widely applied system in the entire manufacturing industry.

Intensive research and development during the last two decades has resulted in spray drying becoming a highly competitive means of drying a wide variety of products.

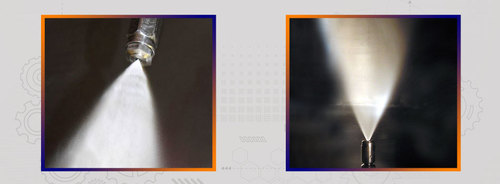

Spray Drying Principal:-

Spray drying involves evaporation of moisture from an atomised feed by mixing the spray and the drying medium. The drying medium is typically air. The drying proceeds until the desired moisture content is reached in the sprayed particles and the product is then separated from the air. The mixture being sprayed can be a solvent, emulsion, suspension or dispersion.

Design of Spray Dryer:-

Fundamentally, the spray drying process is a simple one. However, the design of an efficient spray drying plant requires considerable expertise along with access to large scale test facilities.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

25

Establishment

2012

Working Days

Monday To Sunday

GST NO

24ACGFS0612Q1ZZ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ACGFS0612Q1ZZ

Ahmedabad, Gujarat

Partner

Mr Siddharth J. Nayak

Members since

14 Years

Address

235, Pushpam Industrial Estate, Nr. Nika Tube Cross Road, Phase-1, GIDC,Vatva, Ahmedabad, Gujarat, 382445, India

spray dryers in Ahmedabad

Report incorrect details