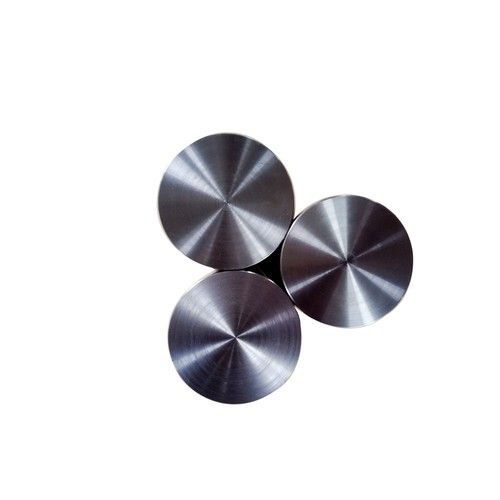

Bright Soft Magnetic Iron Cobalt Alloy Permendur 49

Price: 108.65 USD / Kilograms

Get Latest Price

Minimum Order Quantity :

1 Kilograms

In Stock

Product Specifications

| Strength | 1325 MPa |

| Purity | 48.98 % Cobalt Content |

| Hardness | 275 |

| Product Type | Alloy |

| Material | Iron cobalt alloy |

| Alloy | Soft magnetic alloy |

| Moisture | Normal |

| Chemical Composition | Co 49 , V 2 ,Fe 49 |

| Application | Other |

| Dimension (L*W*H) | Diameter 20.0 to 500.0MM Millimeter (mm) |

| Color | Bright |

| FOB Port | ShangHai |

| Payment Terms | Telegraphic Transfer (T/T) |

| Delivery Time | 25 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | Export standard wooden Packing |

| Main Domestic Market | All India |

| Certifications | CQC ,ISO9001:2015 |

Product Overview

Key Features

PERMENDUR 49 is a high saturation magnetic induction strength iron cobalt vanadium soft magnetic alloy. In the existing soft magnetic materials, the alloy has the highest saturation magnetic induction 2.4T and a high Curie point 940 C. Due to the high saturation magnetic induction, when manufacturing a motor of the same power, the volume can be greatly reduced, and the weight can be reduced, which is less than 50 percent of that of an ordinary motor. Moreover, the motor has high sensitivity, low heat generation, good stability and long life. Due to the high Curie point, the alloy can be operated at higher temperatures where other soft magnetic alloy materials have been completely demagnetized and maintain good magnetic stability. The performance stability of the motor is better than that of the permanent magnet motor at higher operating temperatures.

The alloy is melted using Vacuum Induction Melting VIM techniques.

SPECIFICATIONS: ASTM A801-14 Alloy 1, Equivalent to UNS K R30005

CHEMICAL COMPOSITION,Percentage

C 0.01 , Mn 0.15 , Si 0.15, P 0.015 S 0.01 , Ni 0.25 , Cr 0.10 ,Co 47.5-49.5 , V 1.75-2.10 , Fe Bal.

TYPICAL VALUES OF DC-MAGNETIC PROPERTIES- after magnetic final annealed

Induction (B) at 1600A/m 2.116T

Induction (B) at 4000A/m 2.329T

Induction (B) at 8000A/m 2.371T

Coercive force, Hc 98.47 A/m

Notes:

Typical values measured on wound cores solid material DIA.3.937 in/ 100.0mm after annealing treatment at 1150 C in dry pure hydrogen

FEATURES:

Highest Saturation magnetic induction

Higher curie temperature

High magnetic flux densities

High magnetostrictive coefficient

C. maximum permeability

Low D.C. coercive force and low A.C. core loss

FURTHER PROCESSING -Heat Treatment

A final heat magnetic final annealing is mandatory for achieving the magnetic and mechanical properties. The necessary growth of the grains in the material, and hence the accompanying improvement in the characteristic magnetic values, only occurs during the final annealing.

The maximum magnetic properties of PERMENDUR 49 are best achieved by annealing for 5 hours at 1150 C to 1155 C in a pure dry hydrogen atmosphere (-40 C dew point). Cooling in the blow 1150 C to 870 C range at 50 C per hour and 870 C to 750 C at 50 C per hour,750 C to 300 C at 200 C/hour is recommended. In order to retain the maximum properties this anneal should be done after all manufacturing of the part is completed.

XAGY does not sell PERMENDUR 49 products in the magnetic annealed condition.but we are provide the option of heat-treatment processing techniques and Recommendations!

APPLICATION: Rotor and Stator laminations in motors and generators

FORMS OF SUPPLY

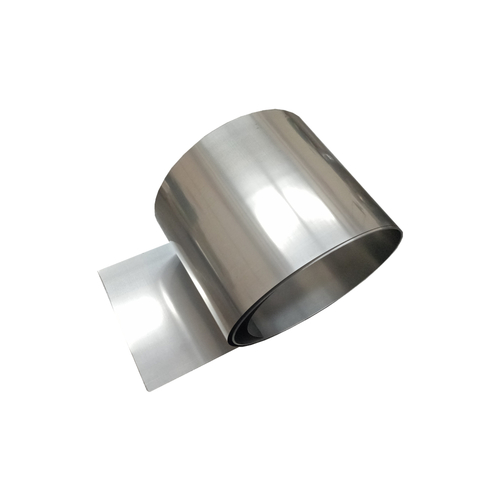

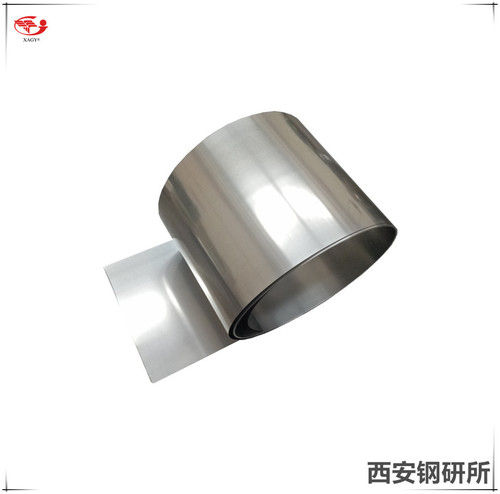

STRIP Thickness 0.05MM to 1.51MM

PLATE Thickness 1.52MM to 3.0MM

ROD Diameter 20MM to 500MM

Company Details

XI AN GANGYAN SPECIAL ALLOY CORPORATION Specialized in manufacturing Nickel alloys and Cobalt alloys for more than 27 years,with a company mission to provide a high quality, reliable source for precision alloys, high temperature alloys and stainless steels in both pilot processing and mass production. We are professionally manufacturing materials with unique features, which are then used in electronics,petroleum and petrochemical industries. Now our company has formally marketed in China s new stock market, stock No. 836660. Base on Quality-oriented, Leading Technology, Continuous Improvement, Customer Satisfaction, we believe XAGY Inc can be your best supplier.

Business Type

Manufacturer, Supplier, Fabricator, Producer

Employee Count

168

Establishment

1993

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO:9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Xian, Shaanxi

Sales Manager

Mr Paul Wu

Address

No. 88 East of Century Avenue, Xiangyang, Xian, Shaanxi, 712046, China

cobalt alloys in Xian

Report incorrect details