Gate Valves

(4102 products)Gate Valve - Application: Industrial

Round

Silver

Different Size

Gate Valve

Industrial

Industrial

Bronze Gate Valve (Flanged Ends), Pn 10 Application: Water

MOQ50 , Piece/Pieces

SealingINTEGRAL SEAT

Usagewater, oil

Applicationwater , oil

StructureGate

TypeGATE VALVES

PowerHydraulic

Casting Flange Type Knife Gate Valve

Price Trend: 350000.00 - 1050000.00 INR/Unit

MOQ1 Unit/Units

StructureGate

ConnectionOther

Size2 inch to 48 inch

MaterialCasting

TypeWedge Gate Valve

Power SourceManual

Jayant Impex

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller4 Years

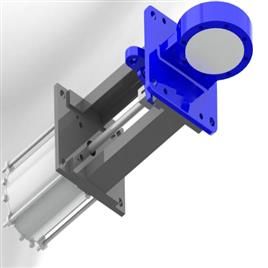

Pneumatic Cylinder Operated Knife Gate Valve

Product DescriptionGiving priority to our valued patron's demand, we are engaged as manufacturer, supplier and exporter of Pneumatic Cylinder Operated Knife Gate Valve in Ahmedabad, Gujarat, India.\015\012\015\012Specifications:\015\012Body : Solid One Piece Casting of CI, CS, CF8, CF8M\015\012Gate : AISI SS 304 / 316

Asten Controls Llp

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

Rapidrop Fig.133FF Valve - Ductile Iron, Lightweight Design | Manual Operation, Red Finish, Corrosion Resistant Components

Price: 10000 INR/Unit

MOQ10 Unit/Units

ColorRed

Product TypeGate Valves

MediaWater

Rapidrop India

Navi Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller8 Years

Krishna Grain Systems Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

24 Inch Stainless Steel Gate Valve - Color: Silver

Price: 4350.0 INR/Unit

MOQ1 Unit/Units

ColorSilver

StructureGate

UsageIndustrial

MaterialStainless Steel

Size24

Product TypeStainless Steel Gate Valve

Skywin Valve Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

Pneumatic Knife Edge Gate Valve - Color: Blue And Silver

Price: 500 INR/Piece

MOQ10 , Piece/Pieces

UsageMachinery

MaterialStainless Steel

SizeStandard

Product TypePneumatic Knife Edge Gate Valve

MediaWater

ColorBlue and Silver

Z-tork Automation Co

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

Rising Spindle Gate Valve - Rising/Non-Rising Spindle Type, Clear Water Up To 450C | Designed For Water Works, Stress Analysis Validated

Product DescriptionFocused on qualitative products and consumer satisfaction with support of our top grade staff, we are engaged in exporting, distributing, trading and supplying a wide gamut of Rising Spindle Gate Valve from Kolkata, West Bengal, India. These gate valves being provided by us are available in non risi

Debson Pumps Pvt Ltd

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

Gate Valve - Stainless Steel Forged, 1/2 Inch to 18 Inch | Controlling Liquid Flow, Available Sub Parts

ColorBlack

SizeMany

Product TypeControlling Liquid Flow

MaterialStainless Steel

TechniqueForged

ConnectionOther

Shree Rajlaxmi Forge

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

Knight Gate Valve - Cast Iron Body, 100x50x200 mm Dimensions | Stainless Steel Gate, 100 psi Operating Pressure, Pneumatic Actuator, 0-80°C Temperature Range

Product DescriptionKnight Gate Valve

Rathi Engineering Solutions Private Limited

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Gray & Golden Gate Valve

MOQ1 Piece/Pieces

Product TypeGate Valve

UsageIndustrial

ColorGray & Golden

MaterialOther, Mild Steel

MediaWater

ShapeRound

Alpha Trading Co.

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller16 Years

Blue-Red Knife Edge Gate Valve With Manual Operating

MOQ1 Piece/Pieces

StructureGate

UsageIndustrial

SizeStandard

Power SourceManual

Product TypeKnife Edge Gate Valve With Manual Operating

ColorBlue-Red

Viral Enterprise

Valsad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Cast Gate Valve - Durable Cast Iron Material | High Flow Capacity, Corrosion Resistant Design, Versatile Application

Product DescriptionCast Gate Valve

Aaa Industries

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller15 Years

Slide Gate Valves - Color: Silver

Price: 8000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Size200x200, 300x300, 350x350 , 400x400 , 500x500 , mm

UsageIndustrial

Product TypeSlide Gate Valves

MaterialStainless Steel

Power SourceManual

Rotech Engineers

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Pneumatic Knife Gate Valve - Metal, Standard Size, Silver Color | Perfect for Water Supply, Low-Allowable Leakage, Designed for Slurries and Pneumatic Conveying Systems

Price: 3250 INR/Unit

MOQ100 , Unit/Units

Product TypePneumatic Knife Gate Valve

UsageWater supply

SizeStandard

ColorSilver

MaterialOther, Metal

TypeOther, Pneumatic Knife Gate Valve

Aircon Pneumatics

Dombivli

Trusted Seller

Trusted Seller Super Seller

Super Seller5 Years

Indian Gate Valve

Product DescriptionWe devoted with Supplying and Trading an professional and considerable variety of Gate Valve in Ahmedabad, Gujarat, India, which are made by working with excellent crude material. These Gate Valve are currently employed for various objective due to its long lasting pursuits and strength. This ranges

Guru Marketing

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Stainless Steel Gate Valves

Price: 1000 INR/Piece

MOQ50 Piece/Pieces

UsageIndustrial Use

ColorGrey

StructureBall

Product TypeStainless Steel Gate Valves

Size1/2" to 2"

ConnectionThread

Bhagyalaxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

150 Mm Pneumatic Manual Slide Gate Valve - Color: Requirement Based

Price: 5000 INR/Unit

MOQ1 Unit/Units

SealingSealed

Sizerequirement based

Voltagerequirement based Ohm (ohm)

UsageIndustrial

MaterialStainless Steel

Product Typerequirement based

Alfa Agro Industries

Bagpat

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

High Quality Gate Valves - Durable Brass Construction | Customizable Specifications for Diverse Industrial Applications

MOQ40 Piece/Pieces

Payment TermsCash on Delivery (COD), Days after Acceptance (DA), Cash Against Delivery (CAD), Letter of Credit (L/C), Delivery Point (DP), Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Steam & Power Engineers

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Stainless Steel Gate Valve - 20 mm Size, High Pressure, Flanged End Connection | API-600, Fire Safe, Bolted Pressure Seal Bonnet, Flexible Wedge

ConnectionFlange Type

Size20 mm

UsageAir

MaterialStainless Steel

Power SourceManual

Product TypeValve

Parmar Steel

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Gate Valve - API 600 Rated, Flanged & Butt-Weld Ends - Rugged Durability, Flexible Wedge Design, Tight Sealing

Price Trend: 5000.00 - 30000.00 INR/Unit

MOQ5 Unit/Units

Supply Ability200 Per Month

Delivery Time7 Days

Sqk Valves Fittings & Automation Private Limited

Navi Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

High Pressure Ball Valve - Alloy Material, Flanged Connection, Port Size 50-400 | Superior Performance for WOG Applications, ISO 9001 Certified

Price: >500 INR/Piece

MOQ1 Piece/Pieces

StructureBall

PressureHigh Pressure

ConnectionFLANGED

MaterialAlloy

Port Size50-400

Flange150, 300, 600

S.H.INDUSTRIAL Needs

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

Carbon Steel Knife Gate Valve - Color: Blue Paint Coated

Price: 20000.0 INR/Unit

MOQ1 Unit/Units

StructureGate

ColorAS PER THE REQUIRMENT

SealingPTFE

Size200 TO 800

Voltage415 Volt (v)

ConnectionOther

Sai Shukla Engineering & Company

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Cast Steel Gate Valve - Carbon Steel, 2 Inch Size | Polished Silver Finish, Ideal for Industrial Use

Price: 2500 INR/Unit

MOQ1 Unit/Units

ColorSilver

Size2 inch

UsageIndustrial

Product TypeCast Steel Gate Valve

MaterialCarbon Steel

SurfacePolished

Sethia Sales & Services

Cuttack

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Efficient Knife Gate Valves - Size: 2.5"

Price: 7000 INR/Piece

MOQ50 Piece/Pieces

Size2.5",3",4" & 6"

ColorSilver and Black

Usageindustrial

MaterialStainless Steel

TypeWedge Gate Valve

Product TypeEfficient Knife Gate Valves

Whale Enterprise Pvt Ltd

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Cast Steel Knife Edge Gate Valve - Color: Blue

Price: 175000 INR/Unit

MOQ10 Unit/Units

ColorBlue

StructureGate

UsageIndustrial

MaterialStainless Steel

Size400 mm

Power SourceElectrical

Halcyon Valves Automation

Howrah

Trusted Seller

Trusted Seller4 Years

Industrial Manual Casted Gate Valves

StructureGate

ColorRed

Product TypeGate Valves

UsageUsed to completely shut off fluid flow

MaterialCast Iron

Power SourceManual

AIRA Gate Valves

Product DescriptionWe are Bengaluru, Karnataka, India based one of the most trusted exporters, suppliers and traders of a comprehensive range of Gate Valves which is highly demanded by our customers for its various characteristics including easy usability, compact design, longer service life, etc. The offered Gate Val

Aira Trex Solutions India Private Limited

Bengaluru

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Gun Metal Gate Valve - Gun Metal, Various Sizes Available, Powder Coated Finish | Affordable Solution for Water Applications

Price: 300/Piece

MOQ1 Piece/Pieces

Sizevariious sizes are available

MaterialStainless Steel

Port SizeVarious sizes are available

Metro Valves And Fittings

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Latest From Gate Valves

Popular Gate Valves

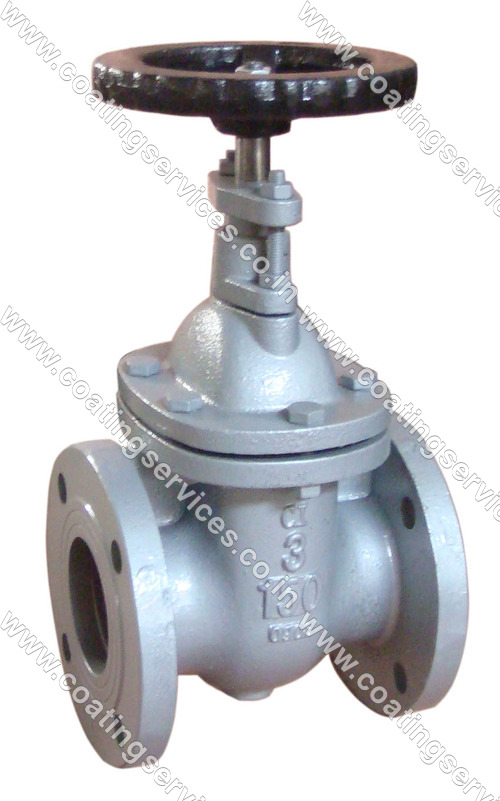

What Is Gate Valves? Types and Parts

To completely stop the flow of fluid in a pipeline or, alternatively, to allow full flow when the valve is fully open, a gate valve is commonly utilized. Thus it is employed either in the fully closed or fully open states. A gate valve comprises of a valve body, seat and disc, a spindle, gland, and a wheel for working the valve. The seat and the gate together fulfil the function of shutting off the flow of fluid. The disc of a gate valve is totally isolated from the fluid when the valve is fully open. Therefore, there is hardly any impediment to the flow. As a result, the pressure loss caused by fluid passing through a gate valve is negligible.

Here are some different kinds of gate valves:

1. Split Wedge Valves

The split wedge is made up of two discs joined together mechanically along a parallel axis.

Both a which-shift and a parallel-disc disc can be present. Even once the fluid is heated, it is not possible to generate a thermal blend.

2. Flexible Wedge Valves

Cuts in the disc's periphery make it flexible, allowing it to withstand the force of heat without deforming. Each and every one of the cuts varies in terms of size, form, and depth.

Because of this, it's also a bit more sturdy. The alignment of the Seat is also optimised by this method, making it more resistant to leaks.

3. Solid Wedge Valves

The solid wedge is one of the earliest and most prevalent types of Gate Valves still in use today. Both horizontal and vertical installations are possible, and it can handle a wide variety of fluids. A turbulent flow is no problem for it.

The problem is that there is a tendency for it to start choking due to thermal expansion inside the pipe, making it more prone to leaking. Because the metal expanded during heating, the thermal locking wedge could not slide between the seats.

4. Screwed Bonnet Valves

These valves are typically supplied as primary isolation valves and include bonnets with an exterior stem thread.

The needle point on the valve stem is fixed in place and there is a cold rolled surface and a rear seat for easy replacement of the valve seat. The die-forged construction of the valve body ensures its durability.

5. Bolted Bonnet Valves

A globe valve known as a fastened bonnet globe valve has its body cover secured with bolts. To create a seal, either a gasket or an octagonal sealing ring is inserted in the middle of the valve.

Parts of Gate Valves

The part of the gate valve that was mentioned above is explained in detail below.

1. Gate

The gate is available in several forms and technologies to ensure reliable sealing in a wide range of settings, but its basic shape falls into one of two categories parallel or wedge.

Slide gates, slab gates, and expanding gates are all examples of parallel gates. There is a second sort of gate valve called knife gates, and its design is comparable to that of wedge valves.

2. Slab Gates

Through-conduit gate valves, or slab gates, are one-piece gates with a bore-sized opening in the centre. When fully open, the bore is centred between the two ring seats. This arrangement allows for a steady, undisturbed current.

3. Parallel Expanding Gates

Sealing is achieved via mechanical expansion of the gate in expanding gate valves, which consist of two slab gates linked together. When the slab gate is opened, fluid can move freely between the two chambers.

An upward force on one slab and the stopping of the second slab by a step in the valve body provide for the necessary mechanical expansion outward for a satisfactory seal.

4. Seat

The gate valve's seal with the gate is carried out and maintained by two seats. The seat of a gate valve may be a separate component or may be included into the valve body. Valve seat rings are either threaded into place or pressed into place before being sealed welded to the valve body.

The latter structure is preferable for use in higher temperature environments. The valve seat can be either pressed in or threaded into the body of the valve, with the latter two providing greater customization options than their integral counterparts.

5. Parallel Slide Gates

Some gate valves have a parallel arrangement, with the gate flat and the seat parallel. In order to create a reliable seal, parallel gate valves utilise the pressure in the line. In the centre of a pair of flat gates is a spring, forming a three-part structure.

The spring forces the components closer to the seats, improving their ability to seal. Because of its construction, parallel gate valves are more secure in high-temperature settings.

Wedge-shaped gate valves can experience heat binding and expansion limits if there is too much pressure on the seats.

In addition, closing torques are lowered due to the lack of wedging action in parallel gates, which allows for smaller, less manual effort or less expensive actuators. Clean seating surfaces are maintained with sliding parallel gates that trap dirt.

6. Sharpened Gates

The lower surface of a knife gate valve is tapered like a knife, making it ideal for cutting through various materials. These valves don't require regular maintenance because they clean themselves every time they open and close by passing the seat rings.

Gate Valve Vs Ball Valve - Key Difference

Is a ball valve better than a gate valve? Can’t be answered until they first establish what makes the two types of valves distinct from one another. The first thing to keep in mind is that they both perform essentially the same purpose.

Ball valves and gate valves differ mostly in terms of their construction and markings. Ball valves have a stem and ball that turn in a horizontal plane, whereas gate valves open by moving a circular or rectangular gate out of the way of the fluid. The ball valve is a rotational valve because of its feature. The gate and the seats of a gate valve are separated by a sealing surface. They are commonly utilised in situations calling for minimally obstructed, straight-line fluid flow.

Ball valves perform differently than other types of valves because they are quarter-turn valves. To regulate the flow, they employ a hollow ball that is perforated and pilotable. When the hole in the ball is towards the direction of flow, the valve is in the open position. The valve's handle, which is flat and parallel to the flow when open but perpendicular when closed, is used to close the valve. This allows for quick visual verification of the valve's operational status.

Gate Valve vs Butterfly Valve: Key Difference

Differences Between Butterfly Valves and Gate Valves.

-Gate Valves

The primary role of a valve is to act as a gatekeeper, as suggested by the device's name. The gate itself is the most important component of a gate valve. Depending on its position, a gate inside the valve either opens or closes the passageway. The internal gate can be raised or lowered using a screw or lever to facilitate movement. A gate valve can be any size or shape, though typically they are quite big. Consider the water mains and the valves that regulate water flow. Large as they may be, gate valves are intended to be operated by a single person.

-Butterfly Valves

A butterfly valve, a clever variant of the more common gate valve, can be found in a wide range of sizes and configurations. A similar internal gate is used in such a valve. The internal operation of the gate distinguishes this from a traditional gate valve.Similar to the gate valve, the butterfly valve can either allow or restrict flow. It is crucial to consider the pros and cons of each valve type before making a final decision.

Difference Between Gate Valves and Globe Valves

The points can easily tell the difference between a gate valve and a globe valve.

1. Typically, globe valves are used to regulate flow, while gate valves are used to completely shut off the flow.

2. Compared to globe valves, gate valves are more affordable.

3. When in their open state, gate valves allow for a relatively unimpeded flow of whatever media they are designed to control. In contrast, globe valves have high-pressure drops and a lot of resistance to fluid flow.

4. The design of a gate valve is straightforward, while that of a globe valve is more involved.

5. Glove valves can be used in both directions, whereas gate valves can only be used in one.

6. Because of the difference in flow direction between the two, globe valves are better at trapping fluid in the line.

In order to allow fluid to pass through, a gate valve (also called a sluice valve) opens by moving an obstruction (the gate) out of the way. With the gate fully open, a gate valve barely slows down the flow of fluid and takes up very little room along the pipe axis.

Best Quality Gate Valves Available Online With Price

Gate Valves are available online with the price list by different suppliers. Buyers can check the gate valve price online offered by the gate valve manufacturers in India. With a large number of companies available online buyers can choose the different types of gate valves easily. They can take a look at the specifications, product details, materials used in the production, quality standards, and others.

Buyers looking forward to buying gate valves should check the features and details, such as:

-Compact Design

-Quality Certifications

-Raw Materials Used

-Delivery Time

-Minimum Order Quantity

-Stock Availability

-Price

Buy Gate Valves Online

Buyers can check the different B2B and eCommerce platforms to buy all kinds of gate valves online. With an online buying facility, buyers can no longer have to worry about physically visiting a market or factories to purchase gate valves. They can check the gate valves and the available sub-categories to get the best product at the most reasonable prices.

-Api Gate Valve

-Forged Steel Gate Valve

-Ci Gate Valves

-Manual Gate Valve

-Knife Gate Valve

-Brass And Bronze Gate Valve

-Leader Gate Valves

Buyers can get the contact details of suppliers and send them all their requirements for purchasing the best quality gate valves.

FAQs: Gate valves manufacturers

Q. What is a gate valve and used for?

Ans. A gate valve is a type of valve that controls the flow of a liquid or gas by raising or lowering a gate or wedge that is located inside the valve body.

Q. How does a gate valve work?

Ans. A gate valve works by opening or closing a gate or wedge that is located inside the valve body. When the gate is in the open position, fluid can flow through the valve. When the gate is in the closed position, fluid is blocked from flowing through the valve.

Q. What is the difference between a gate valve and a check valve?

Ans. Gate valves are opened and closed by turning a handle, while check valves are opened and closed automatically by the pressure of the fluid.

Q. How can I find a gate valve manufacturer in India?

Ans. Finding gate valve manufacturers is simple with leading search engines like Google. You can simply type gate valve manufacturer with your specific location to get suggestions to choose from.

Q. What is a stem in gate valves?

Ans. The stem in a gate valve positions the disk correctly. It can be either rising or non-rising. It is normally threaded which attaches to the handrail for controlling the flow of media.

Q. What is called the seat of a gate valve?

Ans. The seat of a gate valve is that part of the valve where the disk snugly fits in to block the flow of liquid or gas. It is also sealed by an o-ring for preventing leakage.

Q. What kind of media a gate valve is suitable for handling?

Ans. A gate valve is suitable for handling different types of liquid and gas across several industries. However, it is an ideal valve for slurries that contain granules, solids, and powders.

Q. How gate valves are protected from corrosive materials?

Ans. The selection of materials for manufacturing gate valves is done on the basis of the intended application of gate valves. Besides, for extra protection from corrosive materials, the gate valves are coated with suitable paint or varnish.

Q. What are the advantages of a gate valve?

Ans. Gate valves are known for their durability and ability to withstand high pressure and temperature. They are also easy to operate and maintain, and have a relatively low cost.

Q. How do I know if a gate valve is open or closed?

Ans. A gate valve is open when the gate or wedge is in the fully open position and is closed when the gate or wedge is in the fully closed position. Some gate valves have a visual indicator that shows the valve's position.

READ BLOG:

- Top 10 Gate Valves Manufacturers, Suppliers, Exporters in India

- Top Industrial Valves Manufacturers, Suppliers & Exporters in India

- Butterfly Valves Manufacturers, Suppliers & Exporters In India - 10 Best

- Top 10 Air Valves Manufacturers, Suppliers & Exporters in India

- India's Best Quality Top 10 Control Valves Manufacturers, Suppliers & Exporters

- Top 10 Globe Valves Manufacturers, Suppliers & Exporters in India

Manufacturers & Suppliers of Gate Valves

Company Name | Member Since |

|---|---|

Alpha Trading Co. Kolkata, India | 16 Years |

Aaa Industries Mumbai, India | 15 Years |

Viral Enterprise Valsad, India | 14 Years |

Steam & Power Engineers Pune, India | 13 Years |

Asten Controls Llp Ahmedabad, India | 9 Years |

Bhagyalaxmi Engineering Works Ahmedabad, India | 9 Years |

Rapidrop India Navi Mumbai, India | 8 Years |

Z-Tork Automation Co Ahmedabad, India | 7 Years |

Shree Rajlaxmi Forge Mumbai, India | 7 Years |

Debson Pumps Pvt Ltd Kolkata, India | 6 Years |

Popular Products