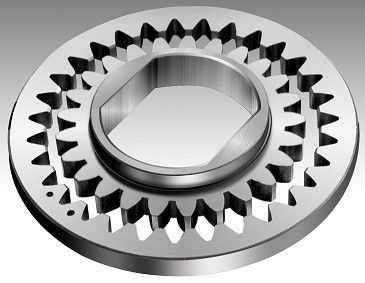

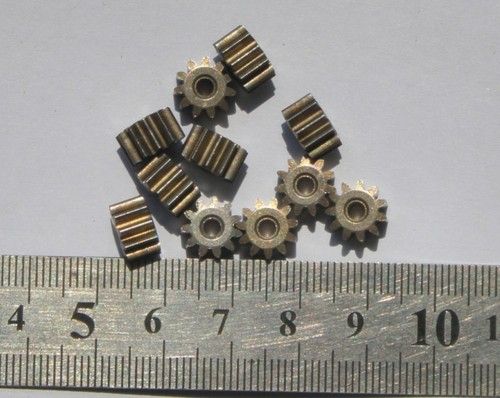

Sintered Gear - Powder Metallurgy, Customizable Dimensions | Fine Surface Finish, Controlled Porosity, Self-lubricating Properties

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Metal Powder |

| Process | Heat Treatment |

| Tolerance | It 6-7 |

| Porosity | Interconnected |

| Application | Self-Lubricating |

| Features | Complex Shapes, High Precision, Surface Finish, Self-Lubrication, Mass Production |

Product Overview

Key Features

ADVANTAGES OF SINTERING:

Complex shapes

Sintering allows to obtain complex shapes directly from the compacting tooling, without any machining operation, like teeth, splines, profiles, frontal geometries, etc.

High dimensional precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered, improvable up to IT 6-7 after sizing. IT 10-13 is achieved in length depending on the component geometry; additional machining operations can improve this precision.

Excellent surface finish

Surface of sintered components is characterized by the presence of flat areas with very low roughness, interspersed with dips corresponding to the porosity. This surface state is better than that of machined wrought materials, which feature an alternate series of peaks and troughs. The lower peaks presence allows to reduce the run-in time of the components.

Reliability and repeatability on large mass production

The tool stability, the technical complexity of the production devices, and the SPC control system, give high reliability and repeatability to the mass production sintered components.

Self-lubrication

The interconnected porosity of the material can be filled with oils, obtaining then a self-lubricating bearing.

Company Details

Focusing on a customer-centric approach, Goa Sintered Products Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Bushings & Bushing Parts in bulk from Goa Sintered Products Pvt. Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1979

Working Days

Monday To Sunday

GST NO

30AAACG6210D1ZJ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 30AAACG6210D1ZJ

Margao, Goa

Director

Mr. Rahul Anil Lotlikar

Address

450/2, Navelim, Salcete, Near Power House, Margao, Goa, 403707, India

sintered gears in Margao

Report incorrect details