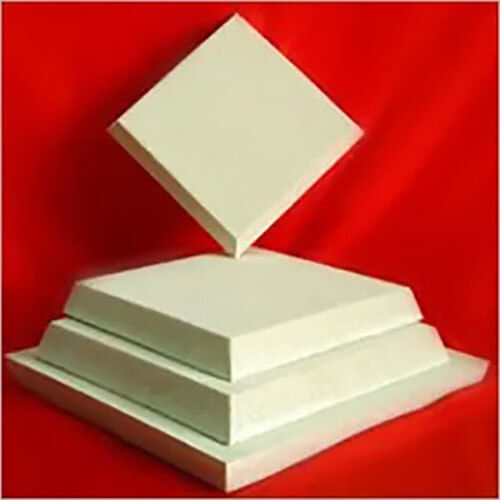

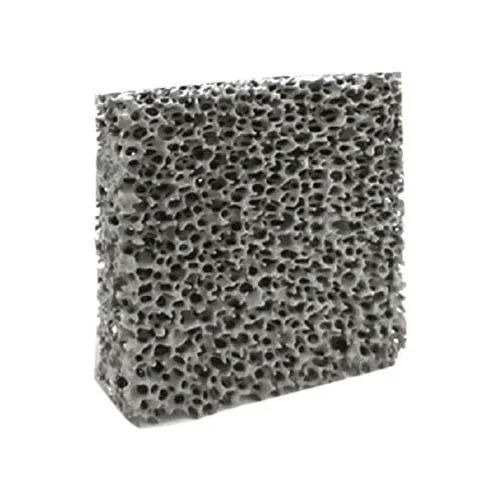

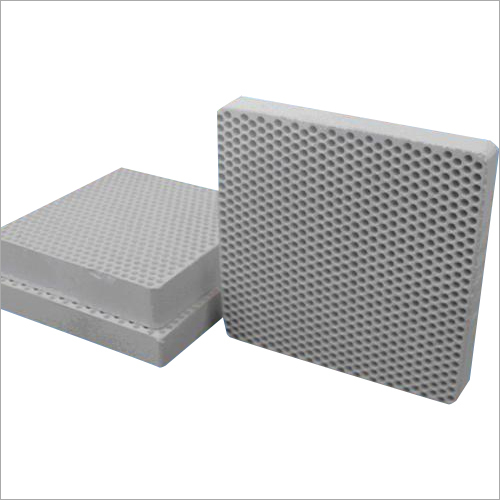

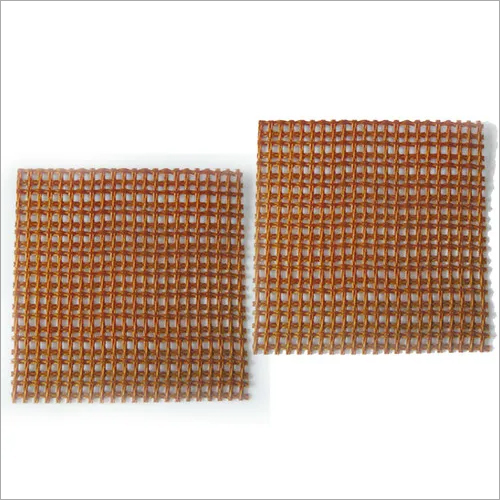

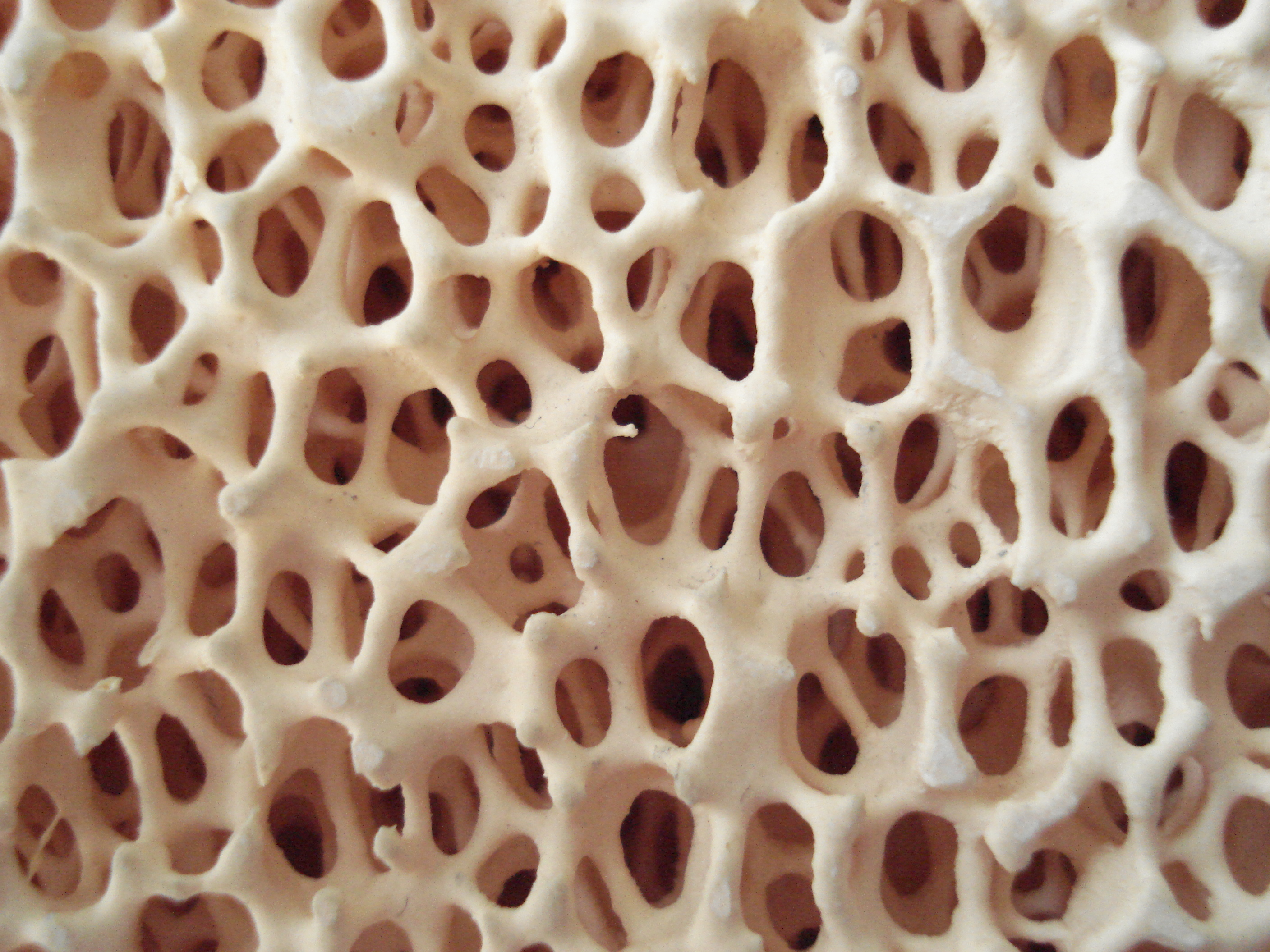

Zirconia Ceramic Foam Filter - 40-500 Mm Diameter, Yellow Color | Industrial Depth Filter Cartridge, 80-90% Efficiency, 2-45 Kg/s Filter Rating, Pore Size 10-30 Ppi, Three-year Warranty

Price Trend: - 50.00 USD ($)

Get Latest Price

Minimum Order Quantity :

1000 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Filter Media | Other |

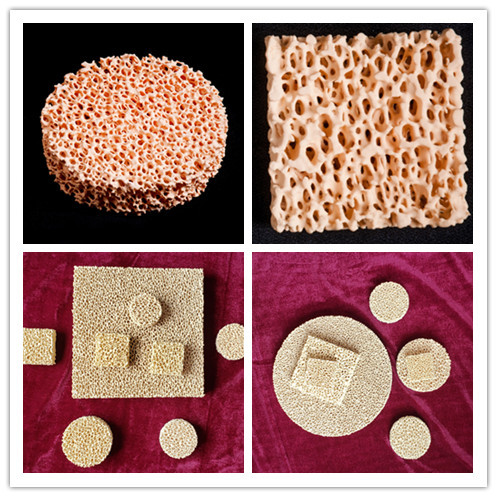

| Length | 40-500 Millimeter (mm) |

| Width | 40-500 Millimeter (mm) |

| Product Type | mass production |

| Usage | Please place the filter close to the casting |

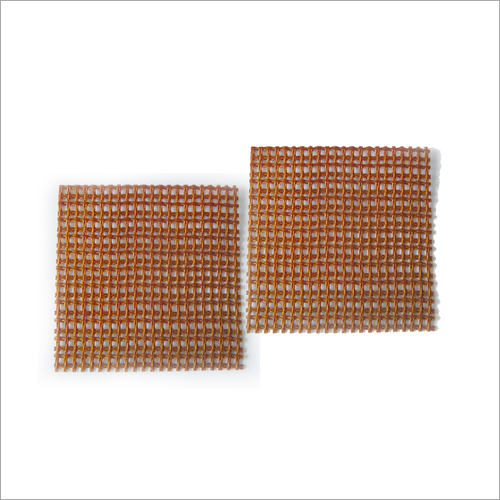

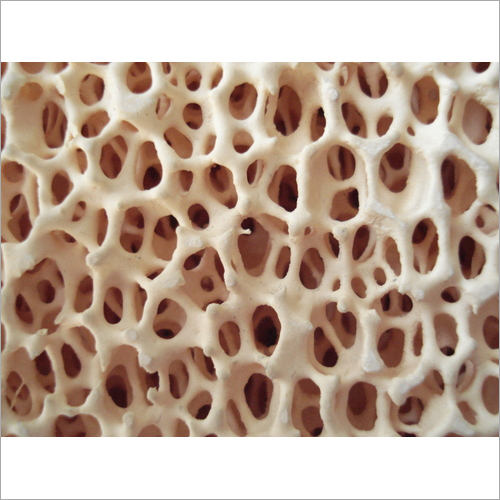

| Pore Size | 10-30ppi |

| Pressure | 1.2 mpa |

| Filter Rating | 2-45kg/s |

| Color | yellow |

| Shape | Round ,square ,custom geometric shapes |

| Height | 12-50 Millimeter (mm) |

| Inlet Diameter | 40-500 Millimeter (mm) |

| Size | 40-500 |

| Outlet Diameter | 40-500 Millimeter (mm) |

| Weight | 25-600 Grams (g) |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Double Open End |

| Diameter | 40-500 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Telegraphic Transfer (T/T), Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Others, Delivery Point (DP), Days after Acceptance (DA) |

| Supply Ability | 2000000 Per Year |

| Delivery Time | 15-25 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | carton and pallet |

| Main Export Market(s) | Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | Function:Ceramic foam filters help to enhanced quality of castings and reduce costSpecial 3 structure to reduce turbulence of flowing molten metal*Reduce defective rate of castings*Improved mechanical properties of castings*Improved precision of dimensions and shapes of castings*Reduced costs of machining operations*Simplify pouring systems and increase utilization ratio of moldQuality Control Process Zirconia ceramic foam filters are manufactured in compliance with the quality control standards ISO 9001-2015.In the process of the ceramic foam filters production the following is performed:A*Control of input parameters of the ceramic raw materialA*Control of theviscosity of the used material A*Control of porosity and other quality parameters of polyurethane foamA*Continuous control and monitoring of technological parameters(dimensions , weight)A*Monitoring of the course of the firing cycle A*Strength test(strength in tension and bending strength) Outstanding advantage :Low abrasion lossLow thermal expansion coefficient High water absorb rate Outstanding crack-resistance |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details