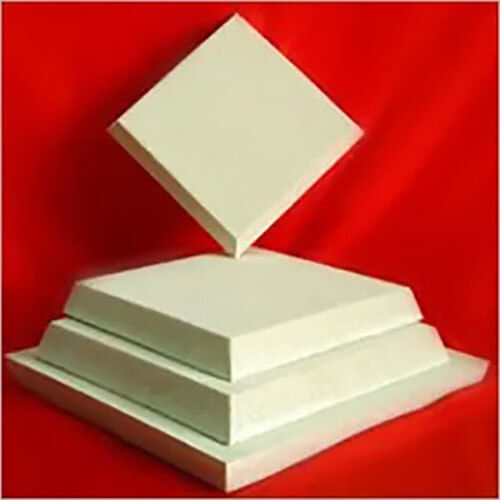

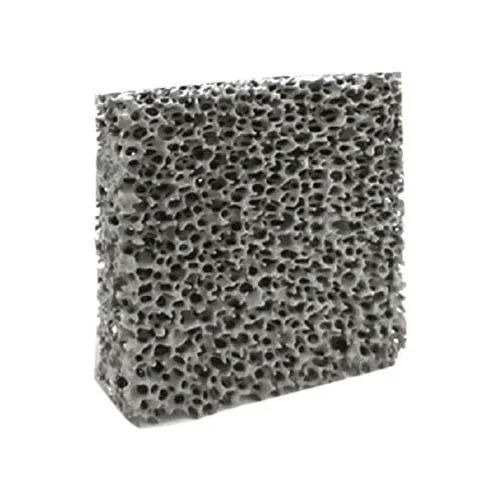

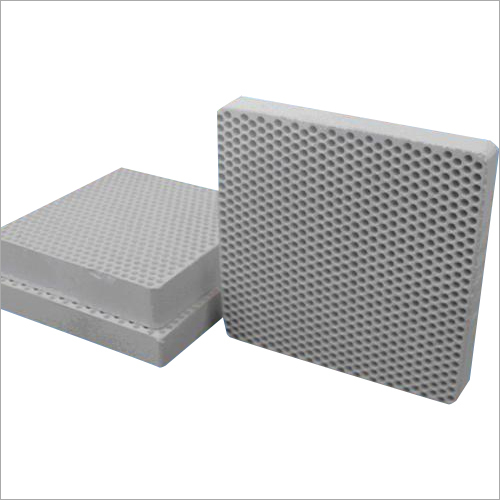

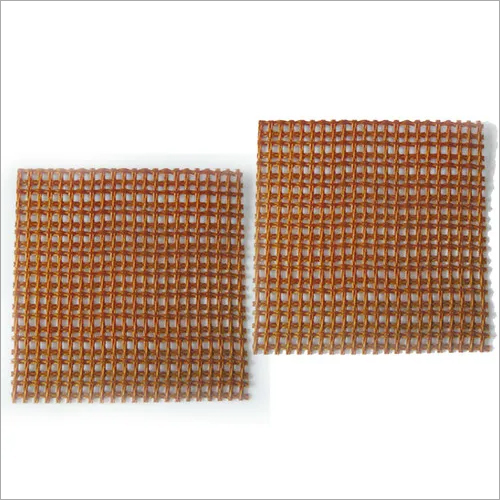

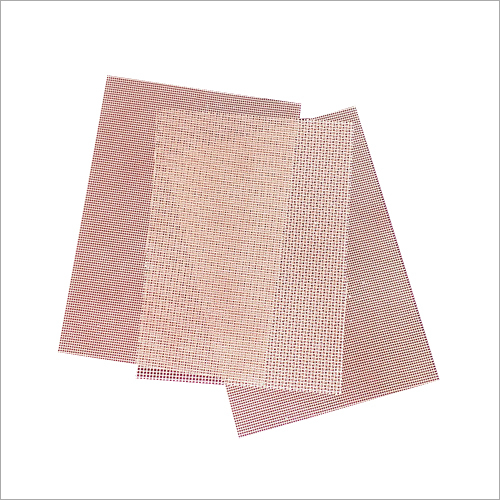

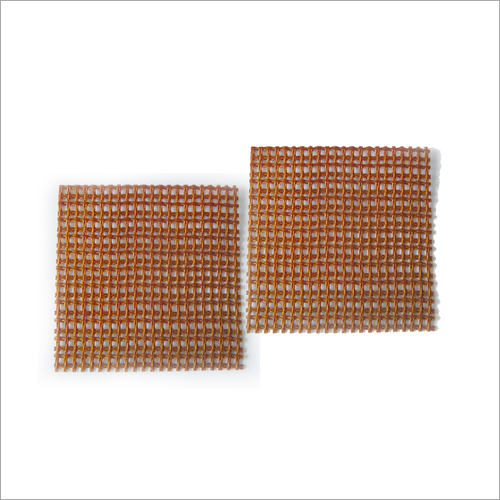

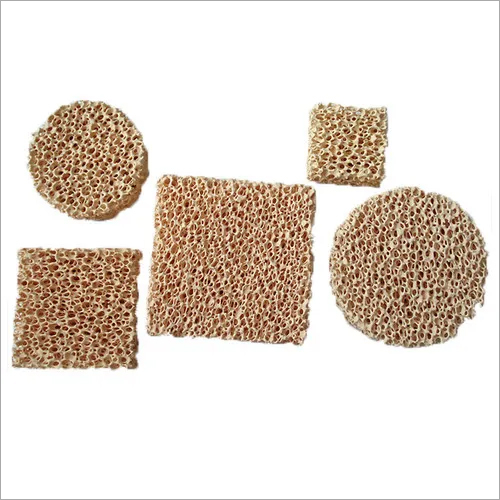

Circular Zirconia Foam Ceramic Filter Diameter: 40-500 Millimeter (Mm)

Price Trend: - 50.00 USD ($)

Get Latest Price

Minimum Order Quantity :

2000 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Pore Size | 10-30 |

| Filter Rating | 2-45kg/s |

| Filter Media | Polypropylene (PP) |

| Color | yellow |

| Height | 15-50 Millimeter (mm) |

| Length | 40-500 Millimeter (mm) |

| Outlet Diameter | 40-500 Millimeter (mm) |

| Inlet Diameter | 40-500 Millimeter (mm) |

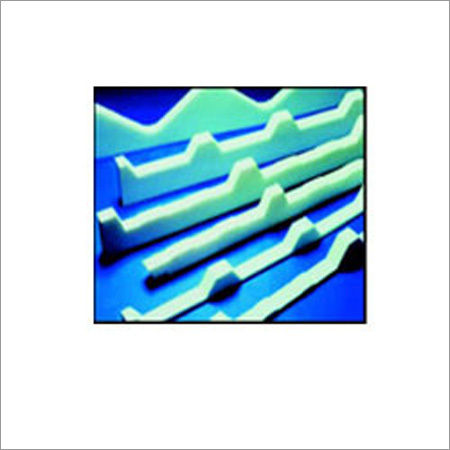

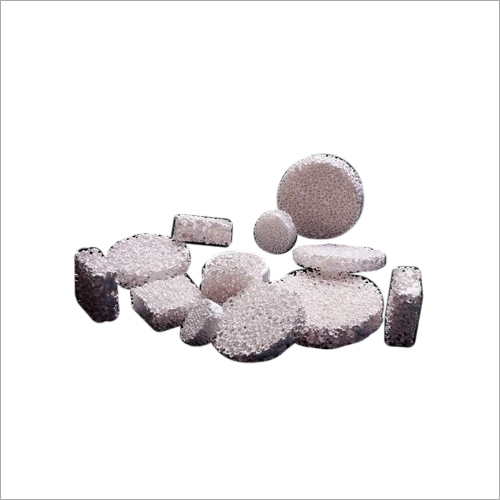

| Shape | Round ,square ,custom geometric shapes |

| Product Type | mass production |

| Weight | 35-600 Grams (g) |

| Usage | Put the filter in casting system |

| Pressure | 1.5 mpa |

| Width | 40-500 Perch |

| Size | 40-500 |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Double Open End |

| Diameter | 40-500 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Others, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Days after Acceptance (DA) |

| Supply Ability | 2000000 Per Year |

| Delivery Time | 15-25 Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | carton and pallet |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

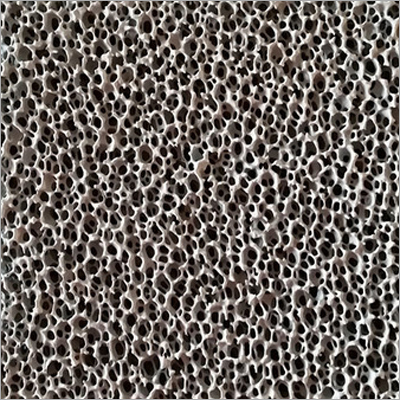

| Certifications | Benefits of using zirconia ceramic foam filterThere are lots of advantages bundled with the use of zerconia ceramic foam filter.- Iron casting and cleaner steel without impeding the chemical plus mechanical property can be found.- Yield of casting is improved whether it is zirconia, extruded or sic ceramic foam filter, the process is accelerated.- Due to the scrap reduction, the production coat is minimized.- Thermal shock traits along with high-temperature strength makes it impoverised for both small and large foundaries.- Through the reduction of inclusions in metal casting, iron and steel foundaries get supper-grade materials.- Available in all standards, shapes and custom size according to the requirement of the foundaries.Zirconia ceramic foam filter helps in keeping the metal purityWhen metal passes through zirconia ceramic foam filterA all the impurities get extraced and the liquid and gaseous content get eliminated in an efficient manner. This is because the extruded filter form has regular shaped honey-comb gaps through which molten form of metal can easily pass.Now going through zirconia ceramic foam filterA the purity is good through an efficient working process. This seems to be a popular method used by various casting industries for both non-ferrous and iron metals |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic foam filters in Cangzhou

Report incorrect details