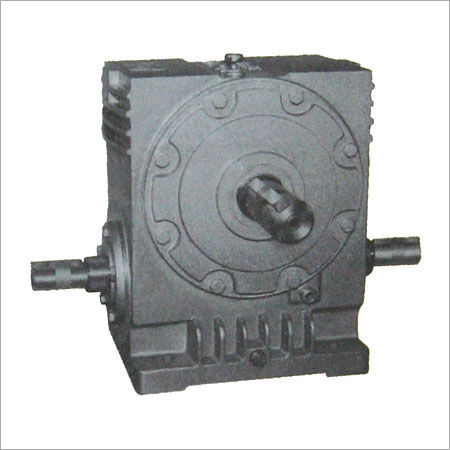

Reduction Gearbox - High Alloy Steel, Heavy-duty Design | High Load Capacity, Low Noise Operation, Efficient Cooling System, Longer Service Life

Price:

Get Latest Price

In Stock

Product Specifications

| Materials | Best Steel |

| Cooling | Fully Cooled |

| Testing | Ultrasonic Tested |

| Lubrication | Excellent Provided |

| Gear Process | Carburization |

| Installation | Foot/Flange |

| Technology | PSRU |

| Features | Stable transmission, High bearing capacity, Low noise, High efficiency, Forced cooling, High strength, Light weight, Easy install |

Product Overview

Key Features

PPRM Designed "Reduction Gearbox"

We offer a diversified gamut of quality approved Reduction Gearbox that is suitable to bear overloads resulting from the flywheel fitted on the input shaft. A reduction gearboxes is used to reduce/minimize an input speed to a slower output speed and also with more output torque, here major involvement of is using with Pulleys/Gears/Sprockets. The offered range is highly appreciated for its high load capacity and overload function, efficiency, safe operation, sturdy construction, less vibration and noise, reliability and longer service life. To meet the varied needs of the clients, this Reduction Gear Box is offered in various specifications according to the needs of the clients.

We are using the Best Steel Manufactures Like VIKRANT Calcutta, MUSCO - Khapoli, WESTEREN INDIA FORGE Pune, VIKRANT Calcutta, ECHJAY Rajkot, BAYFORGE Chennai

Applications : Steel rolling mills, Sponge iron plants, Sugar mills, Cement Industry, Paper industry, Other diversified industries

What is the function of Reduction Gears ?

Reduction gears are used for decreasing the rotational speed of the input shaft to a slower speed as compared to the output shaft and are a part of a mechanical system that consists of gears and shafts. As the output speed decreases it helps in increasing the torque. These reduction gears help in decreasing the speed of the engine, hence used in trucks and automobiles. Reduction gears make a closed system, the input and output power remains the same, as a result speed of the output decreases and proportionally the torque increases. These reduction gears have two gears, which have teeth of same sizes but their diameters are different. Furthermore, the number of teeth are equivalent to the circumference of the gear. Larger circumference gear will have more teeth and smaller circumference gear will have fewer teeth.

Products key Features:

- Stable in transmission & High in bearing capacity

- Low noise & high efficiency

- Forced cooling arrangement & High in mechanical strength

- Light in weight & convenient to install, Compact structure & corrosion resistant

- Designed as per Industrial standards & All Gears are duly hardened ground

- Excellent thermal conductivity to the housing (fully cooled ribs)

- Duplex type with inter-locking system provided

- Complete structure of Gears are Ultrasonic Tested

- Excellent lubrication of Gears & Bearings is provided

- Complete pitches of the gears are precisely tested and trialed

- Heavy-duty and sturdy designs which make suitable to bear overloads

- Excellent rated speed, rated torque, torsional stiffness and backlash

- The process of gear is followed by carburization, quenching and tooth grinding process.

- Installation of Gear Box provided with foot-mounted and flange-mounted

- Its work on PSRU Technology, where PSRU known for "Propeller Speed Reduction Unit

- PP REDUCTION GEARBOX, designed with high technology Propeller Reduction Unit

Our Facilities With Gear Box:

- Gear Producing Machines of HOFLER - Capacity from 21mm up to 2000mm and upto 25 Module with DIN Class 4

- Gear Hobbing Machine - Capacity up to 3000mm in Diameter & up to 25 Module with DIN Class 7

Quick Buyer Details:

| Quick Buyer Details | |

| Production Type | Automatic |

| Export Markets | Worldwide |

| Offers | Maintenance tool kit, instruction & maintenance manual guideline with CD (English) |

| Input material | Alloy, nonferrous, carbon steel |

| Gearing Arrangement | Bevel / Miter / Helical |

| Output Torque | up to 900000N.m |

| Rated Power | up to 3016kw |

| Input Speed | less than 2000rpm |

| Output Speed | 0-2000rpm |

| Mounting Position | Horizontal (foot mounted) or Vertical (flange mounted) |

| Gear material | low carbon high alloy steel |

| Heat treatment | Carburising/quenching/gear grinding |

| Price | Competitive Price, By |

| Warranty | 6 Months |

| Minimum Order Quantity | According your demand, As per buyers |

| Extra Services | After-sales Maintenance & Machining Services Provided |

| Payment Terms | Cash in advance, L/C (Letter of Credit), T/T (Bank Transfer), before shipment |

If you are interested in learning more about our products and services, contact us online or by phone!

Company Details

Focusing on a customer-centric approach, P. P. ROLLING MILLS MFG. CO. PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Gear Boxes, Reduction Gears & Gear Cutting in bulk from P. P. ROLLING MILLS MFG. CO. PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

2002

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Managing Director

Mr. Pankaj Khanna

Address

D-820, New Friends Colony, New Delhi, Delhi, 110065, India

Report incorrect details