Printed Circuit Board Automated Optical Inspection System - Stainless Steel, 950mm X 1000mm X 1580mm, Ivory White | Multiple Algorithms For Defect Detection, High-resolution Imaging, Customizable Maintenance Features

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Color | white |

| Theory | Using multiple algorithms synthetically such as WIDM Color image contrast technology color extracting technology,similarity,two-value handing technology,OCR/OCV etc. |

| Objective | Component Defects:Missing , Misaligned ,overflow ,insufficient ,pasting open, stain |

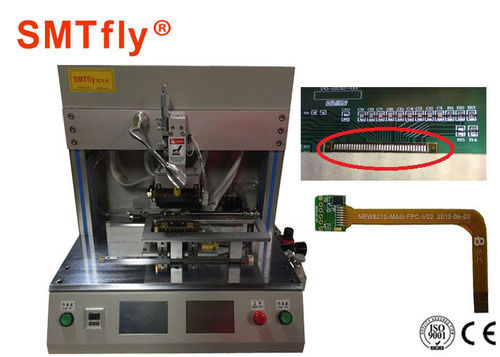

| Product Type | Printed circuit board (PCB) Automated Optical Inspection (AOI) |

| Material | stainless steel |

| Size | 950mm*1000mm*1580mm |

| Weight | 580 Kilograms (kg) |

| Length | 950 Millimeter (mm) |

| Function | Inspection Component Defects and Solder Defects |

| Resolution | 20um(15um/12um/10um for option) |

| FOB Port | Shenzhen port |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Cheque |

| Supply Ability | 100 Per Month |

| Delivery Time | 7 Days |

| Packaging Details | plywood case |

| Main Export Market(s) | Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia |

| Certifications | CE ISO |

Product Overview

Key Features

Features:

1.Multiple-Function

Different AOI model can be placed at several quality controlling points in SMT line such as to check 2D paste printing quality, Check component before reflow soldering, check PCBA quality after reflow soldering, and DIP after wave soldering

2.Simple Interface

Simple software interface accord with daily and effective operation

The work guide, makes the equipment to maintain consistently

The safe is comprehensive and nimble

The Lowest training request

3.Option and customized

Portable tracking doors design, easier for maintenance

With overspecialization it can meet different demands

The machine can work with OK/NG loader, make the seamless connection of on-line testing,PCBreceiving and repairing

With the application of off-line programming and offline debugging ,m-acing the equipment with best value

Various algorithms applications and combination, make the application of software is more flexible

The new algorithm OCR and short test, meet the request of quality ins-software is more flexible

With high intellectualized control system, it can control the quality and give feedback in the first time

Fully meet the requirements of lead-free process

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

52

Establishment

2004

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shenzhen, Guangdong

Mr. Doreen

Address

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, Guangdong, 518103, China

optical inspection system in Shenzhen

Report incorrect details