Polymeric Insulators - Composite Materials, 11-15 Kv Voltage Rating, 307 Mm Creepage Distance | Corrosion Resistance, Heat Insulation, Easy Installation

Price:

Get Latest Price

In Stock

Product Specifications

| Product type | Composite insulator |

| Application | Oil |

| Material | Rubber |

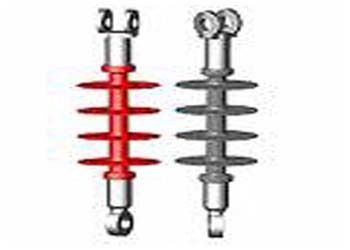

| Color | Red |

| Shape | Cylindrical |

| Features | Strong construction, Corrosion resistance, Heat resistance, Easy to install, Customizable |

Product Overview

Key Features

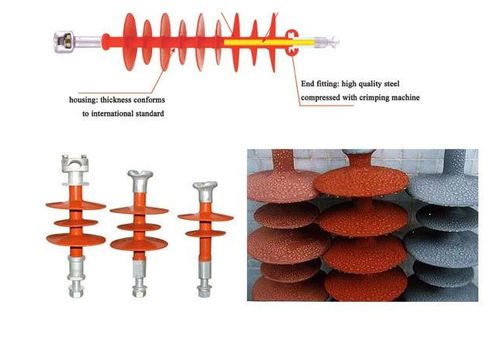

We have successfully manufactured and supplied a wide range of Polymeric Insulators for our customers throughout the country. The offered insulators are precisely manufactured by utilizing quality approved rubber, nylon and other insulating materials with the help most advanced tools and techniques under the supervision of our experienced experts. The provided insulators are used for regulating and controlling the outflow of heat level in the particular medium through pipes, absorbing sheets and insulating rods, demanded in oil, chemical and gas industry. Available at an affordable price range, these Polymeric Insulators can also be custom designed on specific demands of our clients.

Features:

- Strong construction

- Corrosion and heat resistance

- Easy to install

The exterior appearance of a high-voltage insulator depends on a combination of various factors determining its specific shape. Designing an Insulator for optimum performance requires an exact knowledge and description of all application needs. Polytek Insulator design considers following design criteria to ensure excellent field performance and ZERO DEFECT end product.

Mechanical requirements

The mechanical forces such as bending moments, compression, tension, torsion, etc. acting on the insulator and its connecting system must be accurately specified.

Electrical Characteristics

Data such as the lightning impulse flashover voltage, switching impulse flashover voltage and power-frequency flashover voltage define the necessary dielectric strength and insulator length.

Creepage distance requirements

Creepage distances are defined in accordance with IEC 60815 and with customers' requirements.

Applicable standards and testing codes

International standards, codes and test specifications are observed in the manufacture of the product. The design comply with IEC 61109 with up dated ammendments.

Customer specifications and installation requirements

Special requirements (connecting dimensions, diameter, etc.) are considered during design.

Environmental conditions

Environmental conditions at the installation site determine the design and number of insulator sheds

10 - 15 kv Composite Insulators

| Nominal pulse System Voltage kV | Min. Creepage Distance mm | Section | Rated | Wet power freq. 1 min. withstand voltage kV | Dry lighting |

| 11 | 307 | 274 | 45 | 35 | 75 |

| 11 | 450 | 430 | 70 | 48 | 100 |

| 11 | 360 | 330 | 70 | 42 | 100 |

| 11 | 450 | 430 | 100 | 48 | 100 |

| 11 | 500 | 430 | 100 | 48 | 100 |

| 11 | 450 | 430 | 100 | 48 | 100 |

| 13 | 415 | 341 | 70 | 70 | 100 |

| 13 | 418 | 360 | 70 | 35 | 100 |

22 - 28 kv Composite Insulators

| Nominal pulse System Voltage kV | Min. Creepage Distance mm | Section | Rated | Wet power freq. 1 min. withstand voltage kV | Dry lighting |

| 11 | 307 | 274 | 45 | 35 | 75 |

| 11 | 450 | 430 | 70 | 48 | 100 |

| 11 | 360 | 330 | 70 | 42 | 100 |

| 11 | 450 | 430 | 100 | 48 | 100 |

| 11 | 500 | 430 | 100 | 48 | 100 |

| 11 | 450 | 430 | 100 | 48 | 100 |

| 13 | 415 | 341 | 70 | 70 | 100 |

| 13 | 418 | 360 | 70 | 35 | 100 |

33 - 36 kv Composite Insulators

| Nominal pulse System Voltage kV | Min. Creepage Distance mm | Section | Rated | Wet power freq. 1 min. withstand voltage kV | Dry lighting |

| 22 | 603 | 425 | 60 | 60 | 140 |

| 22 | 568 | 333 | 65 | 60 | 140 |

| 22 | 850 | 444 | 70 | 60 | 140 |

| 22 | 635 | 444 | 70 | 60 | 140 |

| 22 | 580 | 349 | 70 | 60 | 140 |

| 22 | 817 | 397 | 70 | 60 | 100 |

| 22 | 580 | 349 | 80 | 60 | 140 |

| 22 | 708 | 365 | 80 | 60 | 140 |

| 22 | 657 | 378 | 80 | 60 | 160 |

| 22 | 622 | 458 | 95 | 60 | 160 |

| 22 | 850 | 444 | 100 | 60 | 140 |

| 23 | 645 | 442 | 70 | 70 | 204 |

| 25 | 643 | 451 | 70 | 110 | 200 |

Company Details

Focusing on a customer-centric approach, Star Industries has a pan-India presence and caters to a huge consumer base throughout the country. Buy Insulation Material in bulk from Star Industries at Trade India quality-assured products.

Business Type

Supplier, Wholesaler

Employee Count

5

Establishment

2008

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Accepts only Domestic inquiries

Proprietor

Mr. Iqbal Sayyad

Address

Plot No. 2/18, Nirmal Niwas, Road no.3, Liberty Garden, Malad West Mumbai, Maharashtra, 400064, India

composite insulator in Mumbai

Report incorrect details