Plc System By Plastech Solutions

Price:

Get Latest Price

In Stock

Product Specifications

| Features | Alarm recording, Mould data files, Injection switching, Holding switching, Dosing stages, Backpressure stages, Open close speed, Thermocouple alarm, Screw interlock, Double core pulling, Shot wt. intrusion, Dosing monitoring, Cycle time monitoring, Auto lubrication, Mould close safety |

Product Overview

Key Features

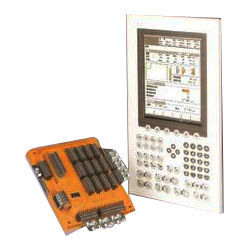

PLC System:

Features:

1. 496 shots actual parameter recording.

2. 96 alarm recording.

3. 100 mould data files.

4. 6 stage Injection, 4 stage Holding switching by timer or switch.

5. 4 stage Dosing & Backpressure

6. 4 stage open close speed.

7. Thermocouple open alarm.

8. Screw interlock

9. Double core pulling program. Controlled by timer/Limit switch.

10. Intrusion for shot wt. increase.

11. Dosing monitoring.

12. Cycle time monitoring.

13. Auto lubrication output.

14. Mould close safety monitoring.

Specifications:

a. 320X240 Monochorme Graphics Display.

b. 69 key tactile keyboard.

c. 24-32 Digital Inputs NPN/PNP 24VDC 10ma.

d. 24-40 Digital Outputs 24VDC 2A

e. 6 Analog output 8 bit 24 VDC 2A.

f. 7 Analog inputs 12 bit.

g. 8 channel PID temperature controller.

Company Details

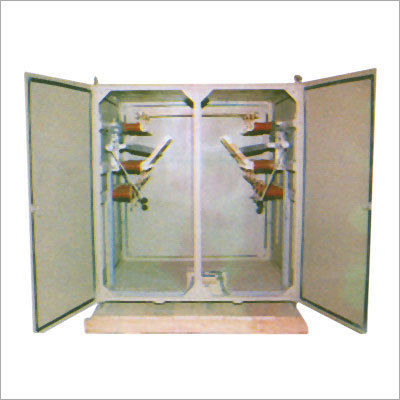

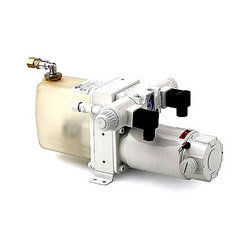

Company deals in below segments 1) Manufacturing of Automotive plastic components 2) Manufacturing of plastic switchgear components 3) Supplier of used plastic injection moulding machines 4) supplier of energy saving servo system 5) supplier of PLC CONTROL SYSTEM for plastic injection moulding machines 6) Industrial 4.0 projects supplier 7) Supplier of hydraulic power packs and blocks and valves and upgradation.

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Trading Company

Employee Count

100

Establishment

2006

Working Days

Monday To Sunday

GST NO

27AAHPZ2501Q1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAHPZ2501Q1Z4

Pune, Maharashtra

Proprietor

Mr. Ajay Zod

Members since

4 Years

Address

Gat No. 48/2, B.U. Bhandari Industrial Estate, Sanaswadi, Ta- Shirur, Pune, Maharashtra, 412208, India

panel in Pune

Report incorrect details