- Tradeindia

- Control Panel Boards

- Electrical Panel Board

Electrical Panel Board

(1992 products)Panel Boards - Frequency (Mhz): 50/60 Hertz (Hz)

6500 INR/Piece

MOQ100 , Piece/Pieces

Protection LevelOther, High

Connectivity TypeWired

Operating Voltage230V/415V

Way3-Way

Panel TypePanel Board

Rated Insulation Voltage1000V

View More

Electrical Control Panel Board Base Material: Metal Base

Price Trend : 50000.00 - 60000.00 INR

Neutral Grounding Panel for Industrial Power Maintenance with 400A

ApplicationMaintaining power

Voltage rating220V

Rated insulation voltage220V

Current rating400A

Frequency50Hz

MaterialStainless steel

National Resistors

Pune

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller Premium Seller

Premium Seller19 Years

Super Premium

Super PremiumHeavy Duty LDPP Electric Panel Board with IP67 Protection

Base materialMild Steel

Surface colorBlue

Cover materialStainless Steel

Protection levelIP67

Product typeElectric Panel

MaterialExtruded Aluminum

Zentech Automation

Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

View More

Electrical Panel Board - Base Material: Mild Steel

Price : 70000 INR

Electrical Panel Board Repair

Price : 1000 INR

Capacity White 32A Single Pole Electrical MCB Board with IP20 Protection

ColorWhite

Poles1P

Current rating32A

Voltage rating240V

ProtectionIP20

Short circuit breaking capacity10 KA

Shreeji Enterprises

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller15 Years

Custom Mild Steel Power Distribution Board for Industrial Use

Base materialMild Steel

Cover materialMild Steel

DimensionCustom (L*W*H)

MaterialMild Steel

Surface colorAny Color

Mounting typeWall-Mount

Shiv Shakti Engineering

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller15 Years

View More

Grey Color Mild Steel Material Electric Control Panel Board

Price : 33000 INR

Electric Panel - High-Performance Steel Construction | Smart Energy Management System, Modular Design, User-Friendly Interface

MaterialSteel

DimensionsCustomizable

Voltage Rating480V

Current Rating1000A

Enclosure TypeNEMA 1

IP RatingIP65

Quanta Electric & Automation Private Limited

Patna

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller3 Years

Portable Electrical Panel Cabinet - Color: White

Price: 80000 INR/Unit

MOQ1 Unit/Units

Product TypeElectrical Panel Box

MaterialSteel

WallSheet Metal

ColorWhite

UsePlant

Gayatri Engimech Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Automatic Rectangular Electrical Main Distribution Board Panel 3

Base materialArmoured Metal

MaterialMild Steel

Protection levelIP54

Surface finishPowder Coated

Supply ability100 Per Month

Delivery time6 Days

Pantek Electricals Private Limited

Gurugram

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Direct On Line Starter Control Panel (Dol)

Enclosure MaterialMetal

IP RatingIP65

Operating Temperature0-50°C

Voltage Rating240V

Current Rating10A

Dimensions300mm x 400mm x 150mm

Selec MiBRX-96-1-0-24VDC Panel Mount LED Digital Relay Controller

ColorBlack

MaterialPlastic

Dimensions96mm x 96mm

Voltage24VDC

Inputs8 Digital

Outputs4 Relay

Apple Automation And Sensor

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller17 Years

Brand Industrial Control Panel Board Mild Steel 2mm Thickness IP54

Base materialMild Steel

Cover materialMild Steel

Voltage rating415 V

Max output current1000 A

Thickness2 mm

Protection levelIP54

Industrial Electrical Control Panel - Steel, 3 Phase, 415V, 20Kw, 50Hz | IP65 Protection, Powder Coated Finish, Current 2A

MaterialSteel

Sheet Thickness1.6 mm

Voltage415 V

Frequency50 Hz

Current2 Amp

PhaseThree Phase

Simplex Automation

Bahadurgarh

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

High Quality Electric Panel Boards MI//EPB-4 25Amp and MI//EPB-2

Surface finishPowder Coated

Voltage rating415V AC

Frequency50Hz

PhaseThree

Ip ratingIP54

MaterialMild Steel

Top Rated Products

Electric Panel - High-Performance Steel Construction | Smart Energy Management System, Modular Design, User-Friendly Interface

Quanta Electric & Automation Private Limited

FAQs Related to Electrical Panel Board

- low voltage switchgear.

- switchboards

- power electrical panels

- Lighting electrical panels

It's possible that an electrical panel has a lifetime of anywhere between 25 and 40 years on average.

Steel Electric Control Panel for Three Phase Systems Rated up to 5000 Amp

Rated operational voltage3Phase

Rated currentUp to 5000 Amp

Form of segregationForm-3b/Form-4b

Degree of protectionUp to IP 54

Dry power frequency withstand voltage3KV For 1 Minute

Short time current65 KA For 1 Sec

Systems And Services Power Controls

Ambala Cantt

Trusted Seller

Trusted Seller Premium Seller

Premium Seller18 Years

Electrical Panel - Mild Steel, 220 Volt, IP55 Protection | 50 Hertz Frequency, Powder Coated Finish, Shock Proof Design, 1 Year Warranty

Mount typeWall Mounted

Voltage rating415V

Frequency50Hz

Rated currentUp to 5000A

Insulation voltage1000V

Short time current65KA for 1 sec

Ensave Energy Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Mild Steel Industrial Electrical Panel Board with Stainless Steel

Base materialMild Steel

Cover materialStainless Steel

Surface finishGI Galvanized

Ip ratingIP55/65

Phase3-Phase

Mount typeWall-Mount/Free Stand

415V 630A Wall-mounted Distribution Panel Board with IP54 Enclosure

Voltage rating415V

Current rating630A

Frequency50Hz

Phases3

Enclosure materialSteel

Mounting typeWall-mounted

View More

Electrical Control Panel Board - Metal Housing, Durable Design | High Voltage Capacity, User-Friendly Interface, Enhanced Safety Features

Price Trend : 10000.00 - 100000.00 INR

Mild Steel Electrical Panel Board with 220-440V Voltage Rating

MaterialMild Steel

Voltage rating220-440V

Frequency50Hz

Surface colorWhite

Surface finishPowder Coated

Ip ratingIP55

Electrical Panel Board - Metal Base, Rated 120/240V | Painted White Finish, Versatile Design

Price: 150000 INR/Piece

MOQ1 , Piece/Pieces

Surface ColorWhite

Product TypePanel Board, Other

MaterialMetal Base

Surface FinishPainted

Rated Voltage120/240 Volt (V)

High Durability Polished Brass Electrical Panel Board Fittings for Eas

MaterialBrass

ApplicationElectrical panel board fittings

TypePanel Board

SizeStandard

FinishPolished

DurabilityHigh

Silvergate Engineering Pvt. Ltd.

Jamnagar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Electric Control Panel - Frequency (Mhz): 50 Hertz (Hz)

Price: 30000 INR/Unit

MOQ1 Unit/Units

Product TypeElectric Panel

MaterialMild Steel

Surface FinishPowder Coated

Rated Voltage415 Volt (V)

Frequency (MHz)50 Hertz (HZ)

WarrantyYes

Electrical Panel Board Flame Proof - Color: Grey

Price: 75000 INR/Unit

MOQ1 Unit/Units

Place of OriginIndia

ColorGrey

TypeAir Conditioner

Power SourceElectrical

Voltage210-220 Volt (v)

Weight (kg)20-60 Kilograms (kg)

Amancio Cooling Equipments

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller21 Years

Finish Heavy Duty Electric Control Panel 415 Volt Rated 5000 Amp Support

Rated operational voltage3Phase

Rated frequency50 Hz

Rated currentUp to 5000 Amp

Temperature rise40 oC above Ambient 45 oC

Form of segregationForm-3b/Form-4b

Degree of protectionUp to IP 54

Panel Board Fabrication - Assembly: No Assembly Required

FeaturesCustomizable design, Durable construction, Easy installation, Reliable performance, Cost-effective solution, Space-saving design, Modular design, Safety features, Enhanced efficiency, Reduced downtime

40 Kvar Capacitor Panel - Base Material: Mild Steel

Base materialMild Steel

Capacity40 KVAR

Voltage440V

Phase3 Phase

Frequency50 Hz

ApplicationPower Distribution

High Voltage Electric Panel Board with Extruded Aluminum

Base materialExtruded Aluminum

Protection levelIP55

MountingWall Mounted

Control panel typeACB with PLC Based HT Line

Phase3 Phase

Voltage11KV / 22KV / 33KV

Electrical Control Panels - Base Material: Mild Steel

MOQ2 Unit/Units

Cooling SystemAir Cooling

Base MaterialMild Steel

MaterialMild Steel

Surface FinishGI Galvanized

Warranty1 Year

Display TypeAnalog, Digital

Electric Panel - Body Material: Mild Steel/ Iron

Price: 150.0 INR/Number

MOQ20 Number

SizeStandard

ColorSilver

Water ResistanceYes

Body MaterialMild Steel/ Iron

AccessoriesElectric panel

Warranty1 Year

3200A,Main Acb Panel - Frequency (Mhz): 50 Hertz (Hz)

Price: 552350 INR/Piece

MOQ1 Piece/Pieces

Surface ColorWhite

Product TypeElectric Panel

MaterialMild Steel

Surface FinishPowder Coated

Rated Voltage415 Volt (V)

Frequency (MHz)50 Hertz (HZ)

Latest from Electrical Panel Board

Popular Electrical Panel Board

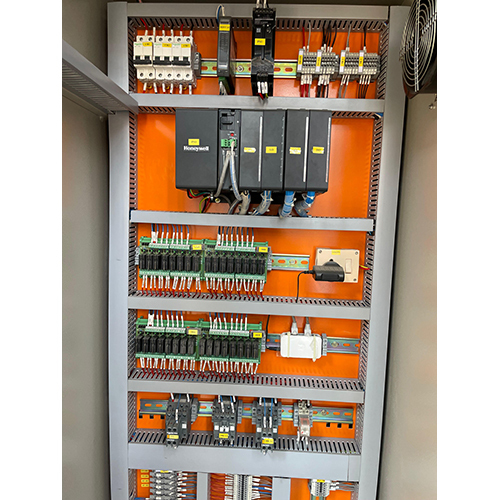

Electrical panel boards are a number one priority for any modern residential, commercial, or industrial electrical system. Electrical panel boards, also known as breaker panels, distribution boards, or fuse boxes, are the 'command center' of a building’s electrical system. Whether you are a homeowner, a tradesman, or simply curious about the safe distribution of electricity, it is important to understand electrical panel boards.

What is an Electrical Panel Board?

An electrical panel board is an enclosure containing circuit breakers, fuses, and bus bars that distributes electricity to branch circuits in a building. The panel board takes power from a main utility line and separates into subsidiary circuits to power lights, appliances, and outlets.Think of it as the control center for the electrical distribution system of a property.

Primary Roles of an Electrical Panel Board

The electrical panel board is the nerve center of a building’s electrical system, and it has several important duties. First, its primary function is distributing electrical power from the main utility supply to the various circuits in the building to ensure that power is delivered safely, and used efficiently, to where it is directly needed. Second, the panel board provides circuit protection by using breakers or fuses that automatically interrupt power in the event of fault conditions that may cause overloads or shortages. This can minimize the risks associated with electrical fires or damage to equipment. Third, the panel board provides immediate access to the electrical system through which users can monitor and control the electricity supply as they consider.

The electrical panel board also permits users to easily isolate or turn off circuits for servicing or maintenance, or to quickly switch off equipment supplying power during an electrical emergency so they can focus their attention on the emergency. This single unit combines the dispersed circuits into one easy to access unit to control and manage all electrical flow in the building, and is essential for operating safely, and effectively, in any residential, commercial or industrial undertaking.

Variations of Electrical Panel Boards

Electrical panel boards come in numerous varieties, each fabricated to fulfill certain functions based on electrical service requirements. The main breaker panel is the most common type of electrical panel, most likely to be seen in residential uses; this panel is equipped with the largest breaker used in the system, which is designed to shut down the total circuit, as well as various breaker boxes for circuits. The main lug panel does not have a main breaker; it is commonly used as a sub panel, receiving power from an upstream main panel. A sub panel itself is secondary paneling that extends the service from the main system localized in the building to other areas, such as garages or additions, providing local control of individual circuits.

The fuse box is an older style of service distribution, instead of having breaker boxes, they rely on "fuses" and replaceable fuses to reset the service. largely older systems, this feature is now obsolete due to safety and convenience. The lighting panel board is used in commercial settings to manage power distribution for "lighting" circuits. Each type of panel board has a distinct purpose in terms of managing the distribution of electrical energy for safe and effective use.

Elements of a Panel Board

An electrical panel board contains numerous components that work in conjunction to distribute and control electricity safely. The main component of an electrical panel board is the main breaker. The main breaker is a device that acts as a primary disconnect switch for the entire electrical system, allowing total power shut-off as needed. Electrical panel boards also include bus bars, typically made of copper or aluminum, which simply carry electricity from the main breaker to the circuit breakers in the panel and ensures overall power distribution. Circuit breakers are also switch-like devices that are mechanically connected to the bus bars; they protect individual circuits from overloads or short circuits by automatically shutting off power, in order to prevent damage to the circuit wiring. The electrical panel board also has neutral and ground bars, where the neutral wires and ground wires from the circuits are connected. It is important to have the grounding connections together for safe electrical operation and to prevent oscillating currents that could result in fire hazards. All of these components or electrical devices are enclosed in a metal cabinet or box, which protects and confines the parts of the electrical panel board, and is used for the safety of users. Arranging the components in the proper order at the electrical panel box ensures proper and safe operation for each individual circuit and consistent functioning of the entire electrical system.

How an Electrical Panel Board Functions

An electrical panel board is a fused box that receives electricity from the utility company through a main power line, which enters the panel and connects to the main breaker. This main breaker allows for the flow of electricity to enter the panel and can cut off electricity to the entire system when needed. From the main breaker, electricity then flows through conductive strips known as bus bars to individual circuit breakers. Each circuit breaker is then attached to a specific area or device in the building, such as light fixtures, appliances, or outlets. When everything in a system is working properly, the circuit breakers allow electricity to flow freely without the use of any fuses. However, if a circuit becomes overloaded or a circuit experiences a short circuit, the circuit breaker will automatically "trip" to cut power in order to prevent damage or fire. A panel board also includes a neutral connection and a ground connection. The neutral carries current back to the electric utility to complete the circuit, and a ground provides a path to move electrical devices into the ground in order to reduce the potential for electrical shock. So we can think of the panel board as a command center that manages, distributes, and helps protect the flow of electricity in a building.

Client Testimonials & Reviews

Prashant

INNOVATIVE POWERTECH

Thank you TradeIndia for your quick and effective resolution. Thanks to you we have been able to grow our business.

Shubh Mittal

Systems And Services Power Controls

We are associated with Tradeindia for our Business promotion since last many years and the inquiries and services being given to us are a good worth for our Business since then. We hope Tradeindia will enhance its service spectrum to a significant extent and give more and more enhanced services to us in near future. We really feel that Tradeindia is an excellent choice for one's B2B promotion on the online marketplace and are satisfied with the services being rendered time and again.

GangaramPatel

APEX ELECTRICALS

We are glad to be a registered member of tradeindia.com. Tradeindia is one of the global platform to provide local and international market of customers it helpful to create more visibility.

PadmasambhavKulkarni

SWAMI SAMARTH ELECTRONICS PVT. LTD.

One of the best online market place for India and Overseas B2B and B2C consumers. Thanks Tradeindia and Team.

Electrical Panel Board Price List

Product Name | Expected Price |

|---|---|

| Electric Control Panel Board | 180000 |

| Electric Control Panel | 400000 |

| Control Panel Board | 5000 |

| Electric Control Panel | 100000 |

| Electrical Control Panel Board | 45000 |

| Electrical Panel | 30000 |

| Electrical Control Panel | 210000 |

| Electrical Panel Board | 50000 |

| Electrical Panel | 150000 |

| Current Distribution Board Panels | 25000 |

This Data was Last Updated on 2025-11-09

Electrical Panel Board Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Amancio Cooling Equipments Vadodara, India | 21 Years |

National Resistors Pune, India | 19 Years |

Systems And Services Power Controls Ambala Cantt, India | 18 Years |

Apple Automation And Sensor Mumbai, India | 17 Years |

Shreeji Enterprises Mumbai, India | 15 Years |

Shiv Shakti Engineering Mumbai, India | 15 Years |

Shorey E-solutions Mohali, India | 15 Years |

Zentech Automation Delhi, India | 13 Years |

Gayatri Engimech Pvt. Ltd. Ahmedabad, India | 13 Years |

Ensave Energy Pvt. Ltd. Ahmedabad, India | 13 Years |

Upcoming Tradeshows

International Crop Science Conference and Exhibition 2026

Mon, 19 Jan, 2026 - Tue, 20 Jan, 2026

India Food Pack Expo 2026

Tue, 20 Jan, 2026 - Thu, 22 Jan, 2026

Asia Labex 2025

Thu, 13 Nov, 2025 - Sat, 15 Nov, 2025

Vyapaar Expo 2026

Fri, 30 Jan, 2026 - Sun, 01 Feb, 2026

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

SVUM 2026 INTERNATIONAL TRADE SHOW

Wed, 11 Feb, 2026 - Fri, 13 Feb, 2026

Automechanika Dubai 2025

Tue, 09 Dec, 2025 - Thu, 11 Dec, 2025

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories