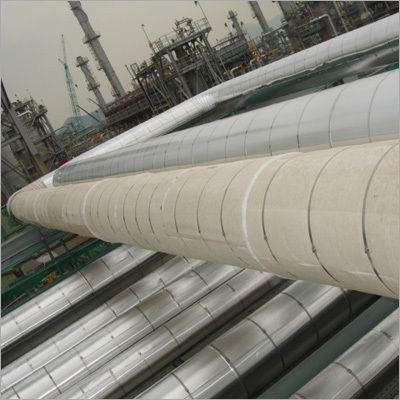

Pipe Insulation With Ss 304 Strap & 45 Degree Bend

Price:

Get Latest Price

In Stock

Product Specifications

| Material | E-Glass Fiber |

| Straps | SS 304 |

| Bend | 45 degree |

| Thickness Reduction | 50% |

| Installation | Simple |

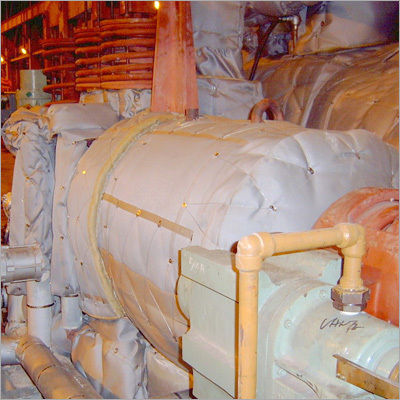

| Usage | Pipe insulation for high-temperature applications up to 500°C. |

| Color | Beige |

| Features | Easy Install, Long lifespan, Reusable, Low corrosion, Consistent size, Durable, 500°C use |

Product Overview

Key Features

E Glass Fiber Thermal Insulation

Distinct Features

Thinner Insulation (by almost 50%)

Due to low thermal conductivity and high density, insulation thickness is reduced by almost half, allowing lighter and compact Rack and hence substantial reduction in Investment.

Consistent Performance over the Long Life Span

Inorganic Binder and Mechanical Needle Punching provide consistent & solid Performance for over two decades essentially outlasts the usual life of the Plant.

Ease of Installation

Quick & simple Installation.

Low Turnaround Time. No requirement of Expert Labor in case of maintenance.

Easy handling for Workers

Easy to Install and Remove Insulation on Live Pipes even up to 500 0C fluid temperatures.

Clean & Reliable Installation

SS 304 Straps to maintain unfailing holding of the Pipe Covers on Hot Pipe Lines without elongation and resultant opening up of longitudinal gaps.

Engineering Fabric Property helps to accommodate zero discrepancy of Standard Pipe Ovality, Pipe Sagging and Welding Joints etc.

Fabric like property helps interlocking the joints (longitudinal and circumferential) requiring no chemicals, adhesives or cements or paste which usually opens up sooner than later.

Reusability

Completely Reusable. No need to sacrifice the insulation after open-up.

Consistent Size & Shape

Maintains Uniform Thickness & No Sagging at Bottom despite human movement on it be it for Maintenance or Laying of additional Pipelines or Painting of Structures which is common cause of the insulation damage in the industries.

Unbreakable still Workable

Virtually unbreakable and withstands physical actions without breakage but still workable to cut in to any shapes to accommodate fittings, supports, accessories etc. Easy to cover virtually any kind of Supports, Fittings.

Low Corrosion under Insulation

E Glass Fiber being an inert material, pH Neutral, Very Low Chloride Content causes less problem of corrosion.

Best Engineering Practices in real application

Preformed Pipe Sections in Rolled form in Two Pieces for virtually any diameter and thickness

Elbows in any Bending Radius in form of ready to use MITRE Bends. Zero tolerance - zero gap.

Inspection plug holes are designed and provided avoids removal of entire elbow for Periodical Elbow Thickness Inspection.

Expansion Joints at required distance to accommodate difference in coefficient of Thermal Expansion of Pipe Material & Insulation Material according to Fluid Temperature, Pipe Material and Thickness of the Insulation.

Minimum use of Screwing due to use of SS 304 Wires/SS 304 Straps for holding the Insulation and Cladding.

Appropriate Overlapping (longitudinal and circumferential ends) of cladding material prevents rainwater seepage in to insulation. Cladding Design also provides for drainage route at appropriate locations for rain water discharge.

ALGC (Aluminum Glass Coated) wrapping provides additional protection for the seepage of water in case of damage of cladding.

Safety

Safe to Humans due to large and continuous non soluble fibers

Non Carcinogenic.

Disposal like any other construction material.

Less Disposal Issues

Due to consistent performance over two decades of life span and reusability causes less disposal requirements unlike frequent replacement need in case of conventional insulation recommended at 3-5 years of interval to generate the intended or design performance.

Company Details

Focusing on a customer-centric approach, DYNAWELD ENGINEERING COMPANY PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Pipes & Pipe Fittings from DYNAWELD ENGINEERING COMPANY PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

200

Establishment

2007

GST NO

24AACCD6424A1ZB

Related Products

More Product From This seller

Seller Details

GST - 24AACCD6424A1ZB

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Manager

Mr. Sachiv Mehta

Address

72/427, Vijay Nagar, Naranpura, Ahmedabad, Gujarat, 380013, India

Pipes & Pipe Fittings in Ahmedabad

Report incorrect details