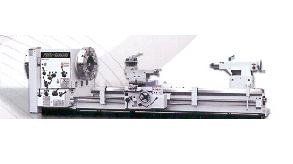

Optical Profile Grinder - Cnc Precision Grinding For Dies, Molds, And Special Tools | Durable, Low Power Consumption, Easy Handling, Rust Resistant

Price:

Get Latest Price

In Stock

Product Specifications

| Type | Profile Grinder |

| Color | White |

| Power | 220V |

| Axes | 3 |

| Usage | Grinding dies, molds, tools, cylinders, and rollers |

| Material | Steel |

| Weight | 1000kg |

| Features | High precision, CNC software, Low power, Durable finish, Easy handling |

Product Overview

Key Features

We

are one of the leading exporters and suppliers of premium quality range

of Optical Profile Grinder. Equipped

with a mounted high reciprocating unit and CNC software, this machine

is used for high precision roughness grinding of various dies and

molds, special tools, cylinders, and rollers. Our associated vendors

manufacture this grinder using high grade components in tandem with

international standards. Clients can purchased offered Optical

Profile Grinder from us in

several designs and other technical specifications at market leading

price.

Features:

Easy handling

Low power consumption

Durable finish

Rust resistance

Description

In our NH family we have separated all movements in X,Y and Z direction. Our objective is to attain a precision of 90+-0 in all 3 axes and to preserve this precision at all times. This provides superior stability even at extreme ends of working range.

The spindle runs in super precision angular contact preloaded bearings with optimum concentricity and balance characteristics.

The spindle head travels in the vertical column in handscrapped guideways with power elevation and manual infeed

The transverse carriage carrying the column traverses firmly on the base on handscrapped guideways via electromechanical drive. This provides intermittent cross infeed.

The table carries out longitudinal traverse only, so that the entire grinding area is at all times fully supported by the slide ways of the front base, even when the table is in its end position.

The column carries out cross traverse only. This ensures the transverse guiding system is always uniformly supported by the rear base slideways regardless of column position. the spindle head only carries out vertical traverse, hence the grinding wheel is always at the same distance from vertical guideways regardless of working height, which in turn ensures absolute parallelism between grinding wheel and worktable.

For large working area, high table loads and very high rates of material removal we offer our BW Series that distinguishes itself by its heavy duty construction. The spindle head as well as vertical cross traverse and table guideways are specially designed for heavy duty cycles.

The Alex low pressure hydraulic unit is located inside the base which establishes a defined thermal state in the machine frame.

Optional: All models are available with CNC controls for automatic grinding cycle including wheel dressing and compensation.

All models can be customized for specific application to suit customer needs.

For Creep feed applications we offer our CF Series. This series focus is on individual production solutions. All 3axes X,Y,Z are powered by servomotors and drives through precision ball screws. feed rates start from a few millimeters to a very wide range on the upper end.

Spindle is of superior rigid construction to handle heavy full cur grinding load.

Coolant system is of very robust design to ensure adequate dissipation of heat.

Dressing system is designed to suit individual application. (Fully automatic cycle to include rapid approach creep feed grinding, auto dressing, compensation and return to home position)

Technical Specifications

| Model |

|

| BW-1000 |

|

Machining Range | Grinding length x width9Max | mm(inch) | 1000x500(40x20) |

| Distance between table and spindle centre(Max) | mm(inch) | 450(18) | |

| Working surface | mm(inch) | 1000X500 (40x20) | |

| Weight carrying capacity of table(Max) | Kg(Lb) | 1000(2200) | |

|

Table | Max.longitudinal movement | mm(inch) | 1050(42) |

| Max. Cross movement | mm(inch) | 550(21.65) | |

| T-slots (number X width) | mm(inch) | 1x14(1x0.55) | |

| Longitudinal Movement | Max Table speed | m/min(ft/min) | 20(65) |

|

Cross Movement | Auto cross feed at each Table reversal | mm/stroke(inch/stroke) | 1-10(0.04-0.40) |

| Manual feed rate/turn | mm/inch | 1(0.04) | |

| Least count of hand wheel | mm/inch | 0.01(0.0004) | |

|

Vertical Movement | Manual feed rate per/turn | mm/inch | 0.2(0.008) |

| Least count of hand wheel | mm/inch | 0.002(0.0001) | |

| Power elevation | mm/min(inch/min) | 100(4) | |

| Grinding Wheel | Diameter X thickness X bore | mm/inch | 350x50x127(14x2x5) |

| Speed | rpm | 1500 | |

|

Motors | Grinding spindle | hp(KW) | 10(7.5) |

| Vertical up down | hp(KW) | 0.75(0.56) | |

| Cross feed | hp(KW) | 0.75(0.56) | |

| Coolant pump | hp(KW) | 0.12(0.1) | |

|

Hydraulic System | Working Pressure | kg/cm2 Lb/inch2 | 15(210) |

| Power of Hydraulic Pump Motor | hp(KW) | 3(2.25) | |

| Tank Capacity | Liters | 200 | |

| Machine Size | Length x Width x Height | mm(inch) | 1890x2900x1890(75x114x75) |

| Weight | Net Weight | Kg(Lb) | 4700(10340) |

| Gross Weight | Kg(Lb) | 5500(12100) |

Company Details

Focusing on a customer-centric approach, J. R. RAO & CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Grinding & Milling Machinery in bulk from J. R. RAO & CO. at Trade India quality-assured products.

Business Type

Exporter, Importer, Supplier, Trading Company

Establishment

1983

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Bengaluru, Karnataka

Proprietor

Mr. U. C. R. Prasad

Address

706, 7th Floor, Devatha Plaza 131, Residency Road, Bengaluru, Karnataka, 560025, India

optical profile grinding machine in Bengaluru

Report incorrect details