Mill Stands - Graded Cast Iron, Multi-groove Roll Design | High-rigidity, Heavy-duty Structure, Quick Roll Change Mechanism, Versatile Configurations

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Varied |

| Roll Diameter | Customizable |

| Power | Variable |

| Weight | Heavy |

| Roll Gap | Adjustable |

| Speed | Variable |

| Features | Heavy-Duty Design, Roll Drafting, Axial Adjustments, Hydraulic Clamping, Constant Pass Line, Versatile Placement, Easy Maintenance, High Rigidity, Quick Roll Change, Compact Design |

Product Overview

Key Features

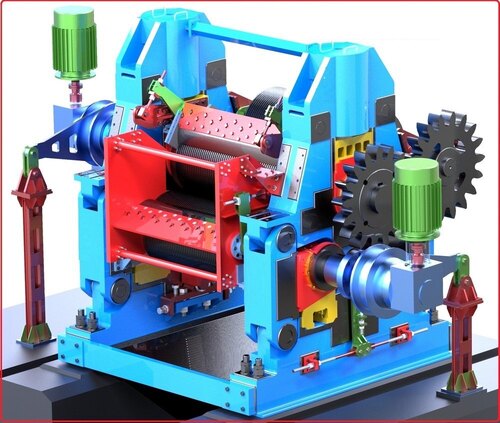

AREW design "Mill Stands"

Mill Stands are the most important instrument in the Rolling Mill Process. It consists of numerous components and systems. The mill stand is usually equipped with two rolls, which are subject to high loads, temperature and efficient working in other extreme conductions. The processed bar passes through the rolls, giving it the desired shape via the roll grooving process and as per the roll passes design. There are various types of mill stand design available in the market suiting the different application need of the rolling process.

Key Features of Rolling Mill Stands

- Heavy duty and sturdy design which is suitable to bear overloads

- Roll drafting arrangement

- Axial adjustments

- Hydraulic stand clamping

- Constant pass line

- Can be placed in both horizontal and vertical configurations

Type Of Mill Stand

- Conventional Mill Stand

- Housing Less Mill Stand

- Cantilever Stands

- Universal Mill Stand

Housing Less Mill Stand Further Classified As

- Vertical Stand

- Horizontal Stand

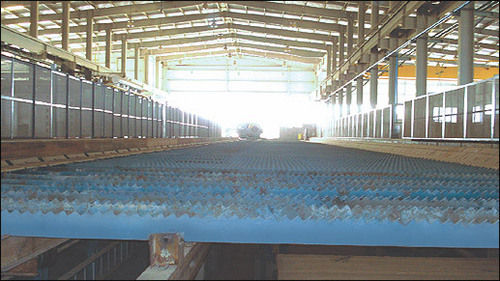

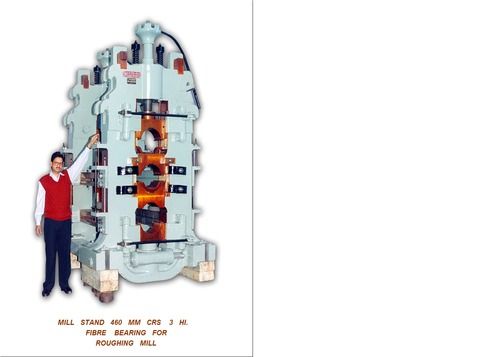

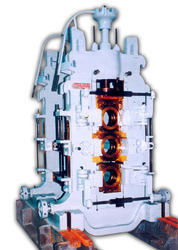

CONVENTIONAL MILL STAND

The Conventional Mill Stand is designed to meet the application needs of various steel industry segments. It is ruggedly built to meet several mill conditions. The Conventional Mill Stand comprises mill spindles, a gear reducer, a roll stand, a pinion stand and a motor. The roll stand slides are provided on the surface of the sole plate for continuous or constant pass line. And, for the low speed rolling mill, with the speed of 18 m/sec, the gear reducer and the pinion stand from a single unit is provided. A cross pin joint of the stand was used for the mill spindle and being supported by the spindle carrier at the time of the rolling process.

HOUSING LESS MILL STAND

The Housing Less Mill Stand has durable roll chocks, which are held tighter by tension screws. It makes it more rigid as well as durable than the conventional stands. The roll chocks are threaded on the both sides (left & right) of the two tension screws. This effective mechanism helps in mathematical opening & closing of the roll gap, which is related to the pass line. The roll changing process in the Housing Less Mill Stand is easy and quick due to its roll changing device. The device pulls out the roll changing assembly and replaces the cartridge without any hurdle. The Housing Less Mill Stand is arranged in Horizontal or Vertical position with no twist arrangement.

Technical Details

- Can be fitted with a set of idler rolls to work the flange

- Has a quick stand change system

- Has vertical and horizontal roll adjustment

- Requires less than two minutes to change position

Advantages Of Housing Less Stands

- Compact Stand & Easy Handling

- Easy Maintenance

- Easy Operation

- High Rigidity

- Saves Installation Space

- Sufficient Reliability

VERTICAL STAND

Vertical Stand is extensively used where the material running speed is high. It is designed to manufacture flats, bars, universal beams, angles, wire rods and other material. The stands can be interchanged very quickly and efficiently as per requirement. It is possible due to the automatic connection and disconnection of the spindles and all fluid utilities.

Following are the striking features of Vertical Mill Stand:

- Automatic screw-down system

- Automatic utility connections

- Axial roll adjustment

- Easy adjustment under load

- Eliminates backlash due to a roll balance system

- Fully automatic operation

- High component rigidity

- Long bearing life

- Reduced stress path

Technical Features

- Bearing: Tapered Roller Bearing

- Chocks: Steel chocks

- Housing: Two open housing

- Material: Graded Cast Iron, M.S. Prime Plate, etc.

- Roll Adjustment: Mechanical type adjustment via the means of Bevel Gear

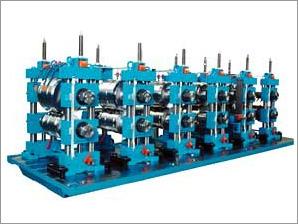

HORIZONTAL STAND

The robustly designed and precision engineered Horizontal Stand is more rigid than the conventional stands. Its roll chocks are properly held together by two tension screws. The stand is developed using the best quality base plates, stand bodies, shafts, couplings and gearbox. Its all gears and gear pitches are stringently tested for quality and performance prior to use. It is easy to install, accurate in dimensions, corrosion resistant, highly efficient and posses longer functional life. Some of the other designing features of Horizontal Stand are cited below:

- Compact

- Durable and reliable

- Easy to operate and safe handling

- Low maintenance

- Sturdy

Core Specification:

- Gives high & optimum performance

- High axial rigidity

- Multi-groove rolls

- Quick roll changing facility

- Supporting stands for high speeds

CANTILEVER STANDS

The Cantilever Stands are available in a variety of sizes for various applications in the industries. The stand is preferred for the use in mill train modifications, wire rod delivery sections, finishing trains, etc. There are several advantages of the cantilever compact stands with roll shafts, which is mounted in floating bearings, such as:

- Quick roll disconnecting mechanism or quick roll changing

- Easy operation

- Quick guide setting and Minimizes the down -time

- Compact in size thus saves installation space

- Short erection time and low erection costs

- Stand shifting mechanism

- High reliability and High level of rigidity

Special Design Features:

- Axial roll ring adjustment requires no maintenance

- Cassette construction

- Large roll shaft diameter and Compact in sizes

- Low weight and Low roll bending

Cost Benefits:

- No need of changing parts, such as assemblies or complete stands

- Requires less labor and Less space

- Lesser changing times

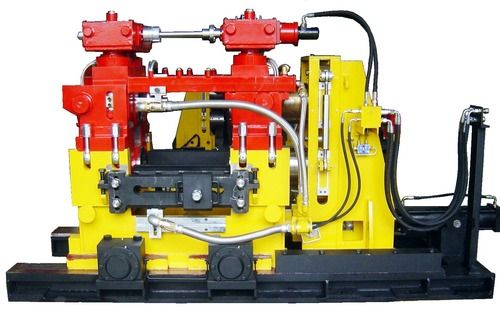

UNIVERSAL MILL STAND

The Universal Mill Stand is a four way rolling stand, which is usually used in the rolling of the section. The section is shaped from all four sides and the stand has both horizontal & vertical sets of rolls.

Company Details

Focusing on a customer-centric approach, A. R. ENGINEERING WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Rolling Mill Machinery in bulk from A. R. ENGINEERING WORKS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

160

Establishment

1985

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

New Delhi, Delhi

Accepts only Foreign inquiries

Mr. Anil Khanna

Address

22, Okhla Industrial Estate, Phase-III, New Delhi, Delhi, 110020, India

Report incorrect details