Maggie Fried Instant Noodles Making Machine Capacity: 30000bags/8hours Cubic Millimeter (Mm3)

Price: 10900 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Noodle making machine |

| General Use | Noodle making |

| Material | Stainless Steel |

| Type | Food Processors |

| Capacity | 30000bags/8hours Cubic Millimeter (mm3) |

| Weight (kg) | 20ton Kilograms (kg) |

| Product Shape | round |

| Computerized | Yes |

| Automatic | Yes |

| Control System | PLC Control |

| Installation Type | Free Stand |

| Voltage | 415v Siemens Volt (S ) |

| Power | 45kw Siemens Volt (S ) |

| Dimension (L*W*H) | 26*6*5 Meter (m) |

| Raw Material | Wheat |

| Feature | Low Noice, Lower Energy Consumption, ECO Friendly, High Efficiency, Compact Structure |

| Color | Stainless Color |

| Warranty | 1 year |

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Telegraphic Transfer (T/T) |

| Supply Ability | 5 sets per month Per Month |

| Delivery Time | 60 workdays after front money Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | Big parts are packed by thick film. Small parts are packed by wooden case. |

| Main Export Market(s) | Western Europe, Middle East, Africa, Eastern Europe, South America, Asia, Central America, North America, Australia |

| Main Domestic Market | North India |

| Certifications | ISO CE |

Product Overview

Key Features

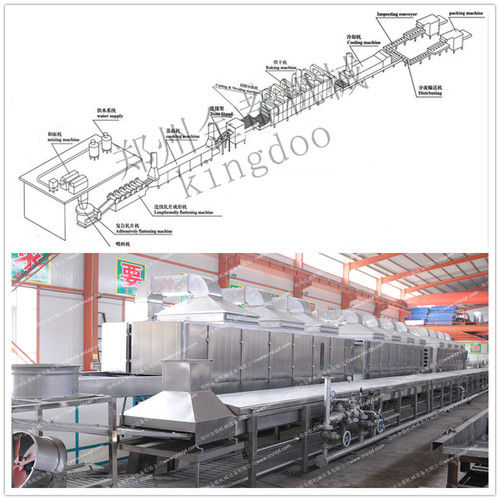

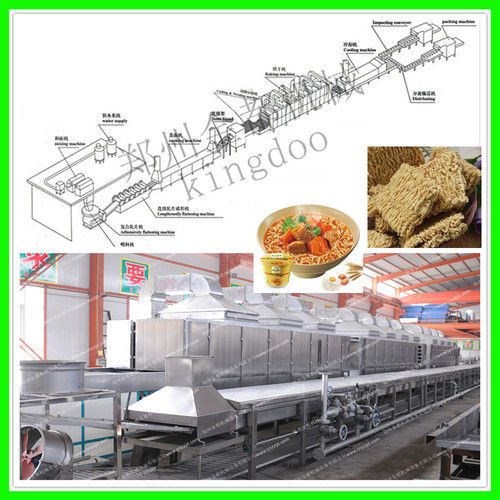

The process flow:

flour feeding-----adding water--------mixing-------dough aging------pressing-------steaming------cutting and dividing------frying------cooling------packing

The equipment of production of production line:-

1. Salt Water Mixer:water mixed with additive such as salt, alkali.

2. Brine metering device: measuring the water demand for every pot flour so as to

control quantitatively the salt water volume from salt water mixer into dough mixer.

3. Dough mixer: flour and water combined and mixed full.

4. Aging machine: dough aging, improve the elasticity of the flour

5. Pressing machine: pressing and cutting

6. Steaming machine: steaming the formed noodles

7. Cutting& Dividing machine: cutting, folding, dividing,, forming the dough pieces and entering boxes, it can form square or circular dough pieces from different molds.

8. Frying machine: dehydrated by frying, fixing the shape of dough pieces, making dough crispy to taste good

10.Cooling machine: lower the temperature of dough pieces to meet the demand of packing.

11. Conveyor: conveying finished instant noodles to each packing line.

12. Packing machine: choosing sauce package packing machine as customersa request, powder packing machine, vegetable bag packing machine, pillow type packing machine (instant noodles in bags), cap-tightener(instant noodles in bowls).

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

50

Establishment

2006

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Sales Manager

Ms Mia

Members since

2 Years

Address

Zhengzhou City, Economic Development Zone Technology, Mazhai Road On The 5th, Zhengzhou, Henan, 450064, China

noodles making machine in Zhengzhou

Report incorrect details