Cetex Ld Lithium Densifier - 24% Total Solids Content, Non-toxic & Eco-friendly Liquid Densifier For Concrete Surfaces, Deep Penetrating Hardening Solution With Abrasion Resistance & Fast Curing Properties

Price: 210 INR / Kilograms

Get Latest Price

Minimum Order Quantity :

60 Kilograms

In Stock

Product Specifications

| Physical Form | Liquid |

| Application | Industrial |

| Shelf Life | 1 Years |

| Storage | Room Temperature |

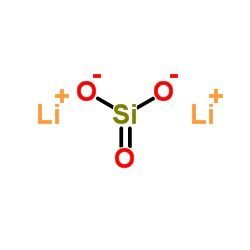

| Ingredients | Lithium Silicate |

| Properties | Total Solids Content : 24% (approx.) Specific Gravity at 25AdegC : 1.20 +/- 0.02pH : Alkaline VOC Content : Nil |

| Poisonous | NO |

| Grade | Industrial |

| Product Type | Nano-lithium based densifier / hardener |

| Appearance | Transparent |

| Ph Level | Alkaline |

| Usage | CETEX LD is concentrated & premium nano-lithium based densifier / hardener for cementatious surfaces. It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance. |

| FOB Port | JNPT |

| Payment Terms | Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA) |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | CETEX LD is available in 60 kg carbuoy and 250 kg plastic drum. |

| Main Export Market(s) | Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO 9001:2015 |

Product Overview

Key Features

CETEX LD is concentrated & premium nano-lithium based densifier / hardener for cementatious surfaces. It is safer, faster and easier to apply. It penetrates deep in the concrete to produce insoluble calcium silicate hydrate within the concrete pores. The increased surface hardness imparted by LD drastically improves abrasion resistance, reduces liquid penetration and dusting and simplifies maintenance.

ADVANTAGES

No scrubbing. No flushing. No wastewater.

By reducing the pores of the surface, it aids in curing of green concrete.

Can be applied on any uncoated concrete or mortar finishes in both new as well as old constructions.

Treated surface is breathable, but seals micro-channels against chemical attack that cause corrosion.

Helps reduce damaging alkali-silica reactions (ASR) and protects from weathering and efflorescence.

Penetrates deep into the surface to improve hardness, compressive and flexural strength of surface.

Provides better abrasion resistance than conventional hardeners.

Reduces application time and costs of diamond polishing operations.

Though it improves gloss and hardness, it does not reduce slip resistance.

Treated surface is breathable, UV stable and maintains natural appearance.

Produces a fast permanent surface gloss which improves with traffic and maintenance.

Makes the surface better looking and dust-proof. Will not yellow, discolour, peel or flake.

Cures quickly. Treated surface can be used within one hour of treatment.

VOC content is nil, thus helps earning LEED points in green building.

It is concentrated. Hence economical for transport. Non-flammable. Non-toxic. Low odor.

Reduces maintenance, cleaning costs and repairs. It is economical to use.

PROPERTIES

Total Solids Content : 24% (approx.)

Specific Gravity at 25A A C: 1.20 +/- 0.02

pH : Alkaline

VOC Content: Nil

APPLICATION METHODS

Clean the surface before application. If there is coating on the surface, for example curing compound, oil, dust etc., it should be removed. Fill and repair all holes, cracks and deteriorated areas. For best result, the surface should be dry to touch to allow diluted LD penetrate the pores and react.

LD is concentrated material and can be diluted with 1-3 parts of soft water for every one part of LD. It can be applied on old or new clean surface by using a low-pressure sprayer, roller or brush.

For Horizontal surfaces, apply enough diluted LD to keep the surface wet for 20 minutes. If areas dry out before that, apply more diluted LD. In hot, dry or windy conditions dampen concrete before application to prevent flash drying. Remove any dried powder residue using a stiff broom, power sweeper or floor scrubbing machine. For immediate, enhanced shine, buff or burnish the dry concrete surface in both directions using an orbital floor machine or burnisher equipped with an appropriate polishing pad. This is a dry buffing operation.

For vertical surfaces, apply from the bottom up. For maximum penetration and desired coverage rates, a wet-on-wet application is recommended; re-treat within three to five minutes after initial application. Repeated applications should be made until the surface remains moist for a minute or so before solution disappears.

PACKING

CETEX LD is available in 60 kg carbuoy and 250 kg plastic drum.

STORAGE

When stored in an airtight, sealed container in normal conditions has a shelf life of 12 months from date of shipment.

Company Details

XETEX INDUSTRIES PRIVATE LIMITED, a leader in the manufacturing industry, has set the bar with its unwavering commitment to quality and exceptional client service. Through our extensive inventory of diverse and customizable products, our talented team goes above and beyond to make sure your needs are not only met, but exceeded. Waltar Enterprises is being spearheaded by Tarun Agrawal, a chemical engineer from the Indias premier institute, IIT Kharagpur. His hands on experience in the field of chemicals has helped to develop innovative and customizable product for the various industries construction, agriculture, speciality chemicals. Our decision to foray into other business is based on our ability to innovate and satisfy customer needs.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Producer

Employee Count

10

Establishment

2006

Working Days

Monday To Sunday

GST NO

27AAACX2263R1ZR

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Certification

ISO 9001:2015 Certified Company

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACX2263R1ZR

Mumbai, Maharashtra

Director

Mr Tarun Agrawal

Members since

15 Years

Address

DBS House, Prescott Road, Fort, Mumbai, Maharashtra, 400001, India

concrete densifier in Mumbai

Report incorrect details