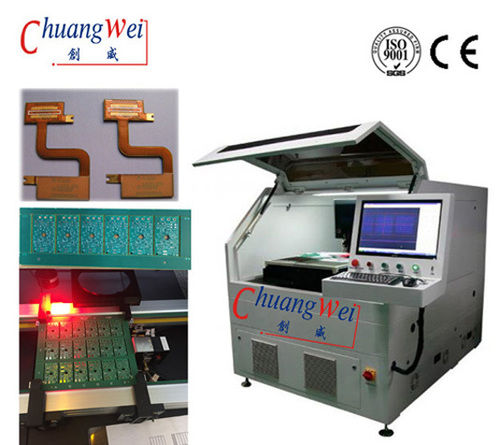

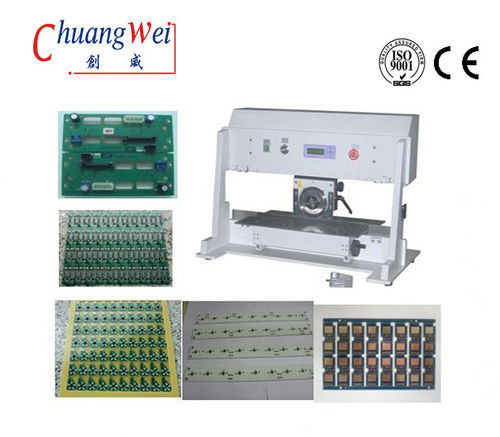

Inline Pcb Router Pcb Depanelers Smtfly-f03

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Motor | High-Speed |

| Control | Rm Based |

| Structure | Rail-Mounted |

| Speed | 60000 Rpm |

| Material | Metal/Plastic |

| Dimensions | Customizable |

| Power | Variable |

| Features | Auto Tool Change, Esd Monitoring, Stress Feedback, Auto Production, Spc Linkage, Explosion-Proof |

| FOB Port | Shenzhen |

| Payment Terms | Paypal, Others, Letter of Credit (L/C), Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 1000 Per Year |

| Delivery Time | 7 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | plywood case |

| Main Export Market(s) | Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia |

| Certifications | CE |

Product Overview

Key Features

Simple Introduction:

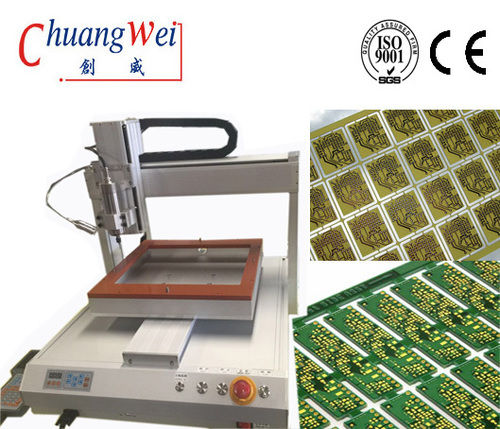

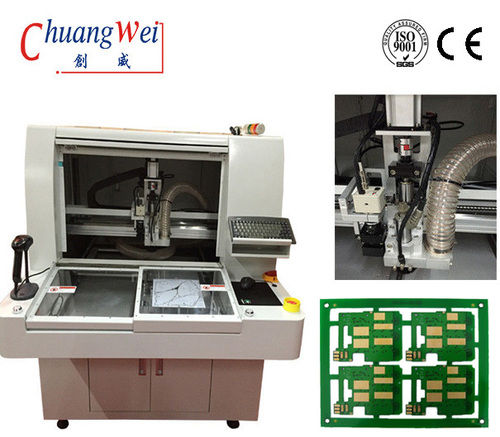

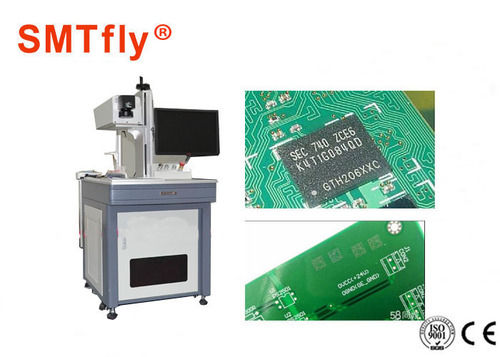

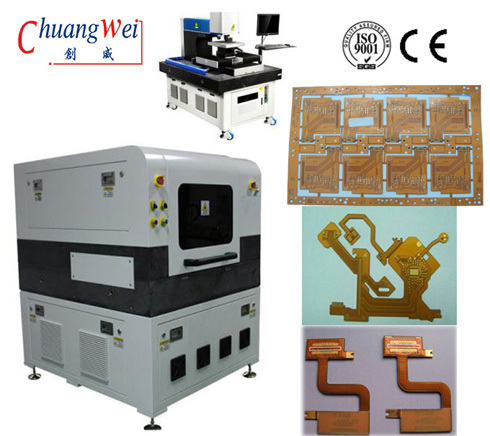

An on-line PCB which is specially used to cut PCBA components(panel) into separate parts, featuring rail-mounted structure without jig cutting. It can be put into production immediately. Featuring ESD static monitoring, cutting stress feedback, and automatic tool changing, it can reach a top speed of 60000 rotates. The control system developed on the basis of our RM system can ensure customer's rapid and accurate programming.

Features:

1. Automatic tool change

2.A ESD monitoring

3.A Cutting stess feedback

4.A Automatic production mode

5.A Linkage between Spc statistic functionand customer's managementA system-ERP

6.A Can be equipped with explosion-proofA function of vacuum cleaner.

ESD ATPD panel forwarding system:

Panel forwarding solution 1: the cut PCB will be delivered by clamping system to belt transmission line, and then sent by ESD transmission line via machine into assembling line, or be picked up and loaded into product case by customized manipulator solution.

Panel forwrding solution 2: use batch panel forwardingA unit ARM-1 dismantle belt transmission line fromA machine, insert panel forwarding unit from behind theA A machine, and directly load the panel into blister boxA in ARM-1 via clamping system. The solution is featuredA By simplicity and convenience.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

52

Establishment

2004

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shenzhen, Guangdong

Mr. Doreen

Address

Add: Building 2, Gang Hua Xing Industrial Park, Chongqing Road, Fuyong Town, Shenzhen, Guangdong, 518103, China

pcb router in Shenzhen

Report incorrect details