Blue Industrial Earthing Electrode

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Marconite |

| Dimensions | Varied |

| Resistivity | 0.001 ohm-m |

| PH | Neutral |

| Strength | High |

| Conductivity | Excellent |

| Applications | Wide range |

| Features | Low resistivity, High conductivity, Easy install, Corrosion resistance, Durable design, Cost effective, Versatile use, Permanent solution |

Product Overview

Key Features

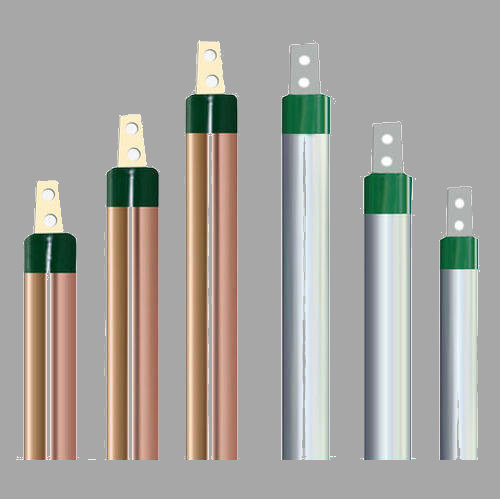

Earthing Electrode

We are specialized in offering a precision engineered range of Earthing Electrode that is an advanced solution for resistant to electrical shocks. Extensively used in various residential, commercial and industrial sectors, this electrode transfers the electric current leakage to the grounds that can cause severe damage to equipments and humans. It is manufactured by our deft technocrats at our technically sound manufacturing unit using supreme quality conductors. Clients can bought this Earthing Electrode in several technical specifications from us at most reasonable price.

Features:

- Rugged design

- High conductivity

- Easy to install

- Resistance against corrosion

Marconite is the worlds premium electrically conductive aggregate material. Used as a backfill to enhance the effects of earth electrodes, Marconite enables electrical engineers to achieve permanent, stable and low resistance earthing solutions, even in difficult ground conditions.

Specifically developed and manufactured for the needs of the earthing industry for over 40 years. Marconite has allowed electrical engineers to tackle the toughest conditions and achieve the satisfactory earthing of installations through out the world.

Marconite conducts electricity much in the same way as metals, through the movement of electrons.

Traditional earthing materials such as Bentonite conduct electricity through the movement of charged ions. These ions require the presence of an effective electrolyte, such as water and the presence of salts. Unlike Marconite, ionic based systems are subject to drying out and without water they do not conduct electricity. Marconite does not need water to conduct electricity and does not suffer any effects from drying out.

Applications:

Marconite has a long and proven track record and has been used within critical earthing solutions to a variety of industries including:

- Lightning conductor earthing

- Power generation and distribution

- Oil and gas production and distribution facilities

- Rail, underground and transport networks

- Telecommunications, High Speed Broadband and Media

- Utilities and Water treatment plants

- Defence facilities and equipment

- Anti-static environments

Benefits:

Low resistivity: 0.001 ohm-m is extremely low when compared to Bentonite's 3 ohm-m

Versatile: Suitable for most ground conditions and becomes a permanent, solid structure and is not prone to shrinking, drying out or being washed away

Cost effective: It is a permanent solution, there is no need to remove, replace or maintain it with additional water/salts every few years in order to achieve the desired earth values.

Chemically inert: is non-corrosive to steel or copper, does not attack cement structures and has a pH value within the neutral range.

High strength: can be used as part of the building structure itself and can achieve strength higher than Grade 25 concrete

Easy to use : forms a concrete like material from first pour, achieves a low resistance earth

Marconite is a synthetic material manufactured specifically for use in earthing applications and, unlike Bentonite, it is not a naturally occurring mineral or ore.

Its distinctive properties result from a unique manufacturing process, utilising specific raw

material feedstocks, carefully selected and mixed in tightly controlled ratios before undergoing a range manufacturing process and thermal treatments.

The end product is a precisely measured, is virtually dust free and with exceptional electrical properties. Then it is packed in high strength, UV resistant valve topped sacks and palletised.

Marconite is the best at what it does because it is manufactured to be that way.

Ease of use and Mixing

Marconite is a dark grey granular material that replaces traditional sand and aggregate materials used within concrete mixes. Lt should be mixed in the ratio of 3 parts of Marconite to1 part cement by weight and addition of 1 litre of water per 5 Kg of total mix, i.e.

- 3 x 25 Kg bags of Marconite

- 1 x 25 Kg bag of Cement

- 20 litres (25 Kg) of water

When mixed as described above, it forms a relatively dry material with an as poured density of around 1300 Kg / m3. The water content may be adjusted as the application requires, but this will affect the concretes compressive strength and drying times accordingly. Typically Marconite concretes are touch dry with in hours but can take several days to fully cure.

Marconite is chemically inert with very low soluble, sulphate content. It can be used with all conventional types of cement, as well as most proprietary resinbased cements,adhesives and gypsum plasters.

Marconite is supplied through out the world via a network of distributors and agents.

Company Details

Focusing on a customer-centric approach, INTER-TECH has a pan-India presence and caters to a huge consumer base throughout the country. Buy Earthing Electrodes in bulk from INTER-TECH at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

12

Establishment

1983

Working Days

Monday To Sunday

GST NO

07AAAFI1510P1ZI

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAAFI1510P1ZI

New Delhi, Delhi

Partner

Mr. Mohit Ahuja

Address

Office No. B-83, Flatted Factory Complex, Near Modi Mill, Okhla Phase-III, New Delhi, Delhi, 110020, India

Report incorrect details