Earthing Electrodes

(1168 products)

Earthing electrode price in India starts from INR 500 to INR 10000. Available in different product specifications like dimension: 10 to 25.0 meters (m), weight: 0.6-10 kilograms (kg), application: electricity, colour: grey and can be available as per customers' requirements.

Related Categories

Brass Electrical & Electronic Components

Bulbs & Tubelight

Cable Terminal, Lugs & Socket

Cable Trays

Cables/Cable Accessories & Conductors

Calculator

Capacitors

Chargers

Circuit Boards

Circuit Breaker

Commercial Field

Control Panel Boards

Dc Power Supplies

Decorative Lights

Diesel Generator Sets

Doorbell

ESD Products & Equipment

Earthing Electrodes

Electric Motors & Engines

Electric Power Tools

Electrical / Lighting Products & Components

Electrical Enclosures

Electrical Goods, Equipment & Supplies

Electrical Outlets

Electrical Product Agent

Electrical Safety Products

Electrical Testing & Measuring Equipment

Electrical Transmission Line Goods

Electro Magnets

Electro Stampings

Electronic Data Systems

Electronic Enclosures

Electronic Instrument

Electronic Liquid Level Controllers & Indicators

Electronic Products & Components

Electronic Safe

Electronic Signs & Sign Board

Electronic Testing Equipment

Electronics Agents

Electronics Stocks

Emergency & Safety Lights

Energy Saving Devices

Fibreglass Cable

Financial Field

Flashlights

Flood Light

Frames & Display

Generator Parts & Accessories

Generators

Heat Resistance Wire

Home Automation Systems

Industrial Automation

Insulation Material

Insulation Paper

Inverters & Ups Equipment

Jacks

LED Displays

LED Products

Lamps & Lampshades

Laser

Light Fittings & Fixtures

Lightning Protection System

Mobile Phones, Accessories & Parts

Outdoor Lighting

Plastic Enclosures

Plastic Welding Equipment

Power Cable Accessories

Power Supplies

Power Transmission Equipment

Pressure Switches

Public Address Systems

Radio & TV

Radio & TV Equipment

Rectifiers

Relays

Residential Lighting

Semiconductors

Sensors

Speakers & Speaker Parts

Stainless Steel Wires & Cables

Switchboard

Switches

Switchgear & Allied Products

TV Picture Tubes

Transformer & Transformer Components

Turbine

Voltage Stabilizers

Water Heater

Welding Equipment

Wires/Cables & Accessories

Wiring Harness

Top Earthing ElectrodesCategories

Explore More Categories

Gel Earthing Electrode Application: Industry

Price: 700 INR (Approx.)/Piece

MOQ- 5 Piece/Pieces

3 Years

Shree Shyam Engineering Company

Indian Inquiries Only

GI Earthing Electrode for 25x3 Tape

Price: 3500 INR (Approx.)/Unit

MOQ - 100 Unit/Units

15 Years

Business Type: Manufacturer | Supplier

AXIS ELECTRICAL COMPONENTS (I) P. LTD.

Verified Exporter

( Accepts only Foreign Inquiry)

Copper Chemical Earthing Electrodes

Price: 1900.00 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Color - Copper

Product Type - Chemical Electrodes

Material - Copper Bonded Steel

9 Years

Business Type: Manufacturer | Supplier

ZARAL ELECTRICALS

Earthing Electrodes Application: Industrial

Price: 1000.00 - 5000.00 INR (Approx.)/Piece

MOQ - 50 Piece/Pieces

Product Type - Earthing Electrodes

Material - Galvanized Steel

Application - Industrial

8 Years

Business Type: Manufacturer | Distributor

SG POWER

Copper Bonded Earthing Electrode Dimension(L*W*H): Dia - 40Mm

Price: 100.00 - 500.00 INR (Approx.)/Piece

MOQ - 100 Piece/Pieces

Product Type - Copper Bonded Earthing Electrode

Material - Pure Copper

Application - Industrial

8 Years

Business Type: Manufacturer | Exporter

AI EARTHING

Silver Gi Earthing Electrode

Price: 1000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Silver

Product Type - GI Earthing Electrode

Material - other, Galvanized Iron

6 Years

Business Type: Manufacturer | Exporter

SAFE EARTHING

Polished Finish Corrosion Resistant Hot Rolled Copper Chemical Earthing Electrode For Industrial

Price: 10000 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Life Span - Long

Strength - High

Product Type - Earthing Electrode

13 Years

Business Type: Manufacturer | Supplier

Allied Power Solutions

Gunmetal B Bond

Price: 100-350 INR (Approx.)/Piece

MOQ - 500 Piece/Pieces

13 Years

Business Type: Manufacturer | Exporter

VISHNU BRASS INDUSTRIES

Copper Coated Earth Electrode

Price: 18500 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Properties - We all know that copper is a very good conductor.Due to its excellent conductive property, it allows more current to flow easily. As there is no corrosion issue, copper lasts longer.Copper earthing electrodes demand very less maintenance. The durability is also impressive.

11 Years

Business Type: Manufacturer | Distributor

ELAPP POWER PRIVATE LIMITED

Round C.I. Earth Electrode Pipe

Price: 700 INR (Approx.)/Meter

MOQ - 100 Meter/Meters

Connection - Other

Shape - Round

14 Years

Business Type: Manufacturer | Exporter

JOY KRISHNA ENGINEERING WORKS

Copper Bonded Rods Application: Earthing

Price: 2,000 INR (Approx.)/Piece

MOQ - 20 Piece/Pieces

Purity - 99%

Product Type - Bonded Rods

Material - Copper Bonded Steel

2 Years

Business Type: Manufacturer | Distributor

SHREENATH ENTERPRISES

Earthing Pipe

Price: 1250.00 - 3500.00 INR (Approx.)/Meter

MOQ - 100000 Meter

2 Years

Business Type: Manufacturer | Distributor

SWASTIK GREEN SOLUTIONS LLP

Industrial Earthing Strap Application: These Products Are Suitable For The Connection Of Dc Resistivity Of Copper Stranded.

Price: 700 INR (Approx.)/Kilograms

MOQ - 20 Kilograms/Kilograms

Product Type - Industrial Earthing Strap

Material - Pure Copper

Application - These products are suitable for the connection of DC resistivity of copper stranded.

3 Years

Business Type: Manufacturer | Exporter

AMA METAL LINK INDIA PVT.LTD

Galvanized Sheet Earthing Electrode

Price: 180 INR (Approx.)/Square Foot

MOQ - 100 Square Foot/Square Foots

Usage - Industrial

Purity - High

Material - Galvanized Sheet

2 Years

Business Type: Manufacturer

ELCON INDUSTRIESS

Galvanized Earthing Electrode Application: Industrial

Price: 100 INR (Approx.)/Kilograms

MOQ - 05 Kilograms/Kilograms

Surface Treatment - Casting

Alloy - Steel

Grade - Industrial

3 Years

Business Type: Manufacturer

PARCO ENGINEERS (M) PVT LTD

Indian Inquiries Only

Indian Inquiries Only

Gel Earthing Electrodes Application: Industrial

Price: 600 INR (Approx.)/Unit

MOQ - 5 Unit/Units

Product Type - Gel Earthing Electrodes

Material - Galvanized Steel

Application - Industrial

2 Years

Business Type: Manufacturer | Supplier

Shree Arihant Enterprises

Indian Inquiries Only

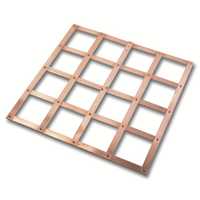

Rectangular Mesh Tem Grids - Copper Diameter: 3.05Mm Diameter Millimeter (Mm)

Price: 12500 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Diameter - 3.05mm diameter Millimeter (mm)

Product Type - Rectangular Mesh TEM Grids - Copper

Application - rectangular mesh grids. Copper

7 Years

Response Rate: 91.28%

Business Type: Manufacturer | Supplier

ARITECH CHEMAZONE PVT LTD.

Ashlok Earthing Electrode Copper Thickness: 3.5 Millimeter (Mm)

Price: 8350 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Copper Thickness - 3.5 Millimeter (mm)

Material - other, Copper

Weight - 22 Kilograms (kg)

17 Years

Business Type: Manufacturer | Distributor

LINK ELECTRICALS (INDIA)

Indian Inquiries Only

Earthing Electrode

Price: 35.00 - 300.00 INR (Approx.)/Piece

MOQ - 6 Piece/Pieces

7 Years

Business Type: Distributor | Exporter

VIJETHA EARTHING SYSTEM

Indian Inquiries Only

Chemical Earthing Pipe

Price: 330-6900 INR (Approx.)/Unit

MOQ - Any Unit/Units

5 Years

Business Type: Manufacturer | Supplier

PROJECTLINE MATERIALS

Cast Iron Earthing Electrode Pipe Application: Industrial

Price: 5500 INR (Approx.)/Unit

MOQ - 100 Unit/Units

Diameter - 250mm Millimeter (mm)

Product Type - Cast Iron Earthing Electrode Pipe

Application - Industrial

Business Type: Manufacturer | Supplier

Veraizen Earthing

Copper Earthing Electrode Diameter: 50 Millimeter (Mm)

Price: 75.00 - 80.00 INR (Approx.)/Kilograms

MOQ - 10 Kilograms/Kilograms

Diameter - 50 Millimeter (mm)

Product Type - Earthing Electrode

4 Years

Business Type: Manufacturer | Distributor

YASH EARTHING SOLUTIONS PRIVATE LIMITED

Indian Inquiries Only

Black Fitel S177 Electrode

Price: 2500 INR (Approx.)/Piece

MOQ - 100 Piece/Pieces

Purity - High

Product Type - Fitel S177 Electrode

Material - Pure copper

1 Years

Business Type: Service Provider | Trading Company

A. K. TELECOM

Indian Inquiries Only

Copper Gi Chemical Earthing Electrode

Price: 6600 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Purity - 99%

Strength - High

Product Type - GI Chemical Earthing Electrode

2 Years

Business Type: Trading Company

SARJU AGENCY

Indian Inquiries Only

Copper Earthing Rod Purity: High

Price: 11000 INR (Approx.)/Piece

MOQ - 100 Piece/Pieces

Purity - High

Material - Pure Copper

Surface Treating - Polished

3 Years

Business Type: Manufacturer | Distributor

U-PROTEC EARTHING PRIVATE LIMITED

Indian Inquiries Only

Silver Gi Earthing Electrode

Price: 5500 INR (Approx.)/Set

MOQ - 1 Set/Sets

Copper Thickness - 3.9 Millimeter (mm)

Diameter - 30-76 Millimeter (mm)

Product Type - Earthing Electrode

7 Years

Business Type: Supplier | Service Provider

BHAWANI ELECTRICAL WORKS

Earthing Electrodes Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Link Electricals (India) | Delhi, India | 17 Years |

| Sanjay Casting & Engineering Company | Howrah, India | 15 Years |

| Axis Electrical Components (I) P. Ltd. | Mumbai, India | 15 Years |

| Joy Krishna Engineering Works | Howrah, India | 14 Years |

| Allied Power Solutions | Delhi, India | 13 Years |

| Vishnu Brass Industries | Jamnagar, India | 13 Years |

| Elapp Power Private Limited | Kolkata, India | 11 Years |

| Zaral Electricals | Vadodara, India | 9 Years |

| Anssen Metallurgy Group Co., Ltd. | Dalian, China | 9 Years |

| Sg Power | Ghaziabad, India | 8 Years |

Top Related Searches Chemical Earthing Electrodes

What are Earthing Electrodes and How Do They Work?

Through electrical cables and low-resistance wires, earthing is a process or technique that transmits the instantaneous electrical discharge directly to the ground. It can be defined more simply as the straight transfer of electrical charge to the earth. By earthing the system, you can prevent electrical damage and gadget malfunction. When the electrical system overloads, earthing serves the primary goal of reducing the load.

Earthing electrodes are installed and specially created to enhance a system's earthing. To decrease resistance, these earth electrodes should ideally reach the moisture content below the ground.

Additionally, they must be made of metal conductors (or a combination of metal conductor types) that do not corrode too much over the course of the anticipated lifespan. Rods or pipes driven into the ground, metallic plates or mats buried in the earth, or a copper wire ring encircling the building are all examples of earth electrodes.

Different Types of Earthing Electrodes

Earthing Plates

Thin copper plates that are buried in close proximity to the soil are commonly used as grounding plates. According to the National Electric Code, ground plates must have a minimum of 2 ft2 of surface exposed to the earth. Non-ferrous materials (copper) only need to be.060 inches thick; metallic materials must be at least.20 inches thick. Grounding plates are frequently positioned beneath rods or as additional counterpoises.

Concrete-encased or Ufer Ground Electrodes

Ufer grounds were initially concrete-encased copper electrodes that surrounded ammunition shelters. Ufer grounds are any electrodes that are enclosed in concrete, including rebar used as a grounding electrode in a structure foundation or wire or wire mesh embedded in concrete.

A building or Ground Foundation

Ufer Grounds or building foundations may be used as long as the rebar is at least 0.500 inches in diameter, the concrete is in direct contact with the ground (with no plastic moisture barriers), and there is a direct metallic connection from the service ground to the rebar buried inside the concrete.

Water Pipe

Water pipelines have been widely employed as grounding electrodes. Because tar coatings and plastic fittings are used, water line connections are not testable and are unreliable. To stop the passage of current and lessen the corrosive effects of electrolysis, city water departments have started installing plastic insulators, especially in the pipelines. When using water pipes as an electrode, at least one extra electrode must be installed, according to the National Electric Code.

Electric arc discharge

The shortcomings of other grounding electrodes were particularly addressed by the electrolytic electrode's design. This active grounding electrode is made of a copper shaft that is hollow and filled with desiccants and natural earth salts whose hygroscopic nature pulls moisture from the atmosphere. The salts and wetness combine to create an electrolytic solution, which seeps into the nearby backfill material and keeps it moist and rich in ions.

Positive Earthing

Through the use of the GI wire, the neutral of the system is immediately connected to the earth during neutral earthing. System earthing is another name for neutral earthing. Such earthing is typically offered to systems with star winding. For instance, the generator, transformer, engine, etc. all have neutral earthing built in.

The Importance of Proper Earthing for Electrical Safety

To safeguard both building occupants and machinery from the danger of high voltage, grounding your electrical systems is essential. A conductive surface, such as metal, can transport enough voltage to deliver a lethal shock when it is not grounded and electrically energised.

Protection from Electrical Overload

One of the most significant benefits of earthing electrical current is that it shields you and the people you love. Additionally, it shields everyone from electric surges as well as your house's equipment. Whatever the cause, lightning strikes or a power surge at your location could result in extremely high electrical volts within your system and cause damage to your property as well as loss of life.

Aids Electricity Direction

If your home or business has a correct electrical earthing system, you will be able to easily direct power in the desired directions, such as fault current to the earth, and it will also help electrical currents move safely and effectively throughout your electrical system.

Maintains stable voltage values

Voltage levels are stabilised as a result. A grounded electrical system also makes it simpler to spread the right amount of power to all the appropriate locations, which can be extremely helpful in preventing overloaded and blown circuits. For the various power sources in an electrical system, the earth serves as a single point of reference.

How to Select the Right Earthing Electrode?

The dirt resistivity at the location of the earthing system installation should be taken into account when selecting an earthing electrode. You might be able to use a smaller or less costly earthing electrode if the soil resistivity is low because the soil will be able to conduct electricity more efficiently.

Innovations in Earthing Electrode Technology

According to experts., big advancements are on the way, including improving the grounding system's core material. Research and development are already underway, and the products being offered are the best in terms of quality and design. A new generation lightning protection system, a variety of surge protection devices for every purpose, freshly created premium grade chemical mixes, new copper electrodes with amazing new designs, and the list goes on are just a few of these offers.

FAQs: Earthing Electrodes

Q. Why are earthing electrodes necessary?

Ans. Every professional who works with electric equipment abides by the health and safety regulations related to electrical installations and the power sector. When developing intricate electric networks and wiring, earthing segments fall under the category of fundamental safety installations.

Q. How does an earthing electrode work?

Ans. Earthing electrodes play a critical role in two grounding system activities. The first, and riskiest, is dispersing the high amperage of a lightning strike away from the structure into the earth. The fault current from a lightning strike is trying to reach Earth in an effort to balance the potential between the ground and the sky, unlike a typical electrical fault, which has its source in the electrical supply and returns to that same electrical supply.

Q. Can earthing electrodes be installed in all types of soil?

Ans. The soil's electrical resistance is measured by its soil resistivity. A low resistivity is frequently sought because low ground resistance is typically favoured or even required in most applications. The ground resistance itself is not as important in some applications as the grounding configuration. High soil resistivity, however, still poses difficulties for these designs and can exacerbate flaws or under-design.

Related Categories

Related Categories

Brass Electrical & Electronic Components

Bulbs & Tubelight

Cable Terminal, Lugs & Socket

Cable Trays

Cables/Cable Accessories & Conductors

Calculator

Capacitors

Chargers

Circuit Boards

Circuit Breaker

Commercial Field

Control Panel Boards

Dc Power Supplies

Decorative Lights

Diesel Generator Sets

Doorbell

ESD Products & Equipment

Earthing Electrodes

Electric Motors & Engines

Electric Power Tools

Electrical / Lighting Products & Components

Electrical Enclosures

Electrical Goods, Equipment & Supplies

Electrical Outlets

Electrical Product Agent

Electrical Safety Products

Electrical Testing & Measuring Equipment

Electrical Transmission Line Goods

Electro Magnets

Electro Stampings

Electronic Data Systems

Electronic Enclosures

Electronic Instrument

Electronic Liquid Level Controllers & Indicators

Electronic Products & Components

Electronic Safe

Electronic Signs & Sign Board

Electronic Testing Equipment

Electronics Agents

Electronics Stocks

Emergency & Safety Lights

Energy Saving Devices

Fibreglass Cable

Financial Field

Flashlights

Flood Light

Frames & Display

Generator Parts & Accessories

Generators

Heat Resistance Wire

Home Automation Systems

Industrial Automation

Insulation Material

Insulation Paper

Inverters & Ups Equipment

Jacks

LED Displays

LED Products

Lamps & Lampshades

Laser

Light Fittings & Fixtures

Lightning Protection System

Mobile Phones, Accessories & Parts

Outdoor Lighting

Plastic Enclosures

Plastic Welding Equipment

Power Cable Accessories

Power Supplies

Power Transmission Equipment

Pressure Switches

Public Address Systems

Radio & TV

Radio & TV Equipment

Rectifiers

Relays

Residential Lighting

Semiconductors

Sensors

Speakers & Speaker Parts

Stainless Steel Wires & Cables

Switchboard

Switches

Switchgear & Allied Products

TV Picture Tubes

Transformer & Transformer Components

Turbine

Voltage Stabilizers

Water Heater

Welding Equipment

Wires/Cables & Accessories

Wiring Harness