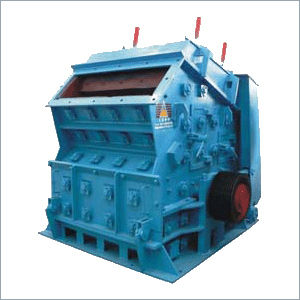

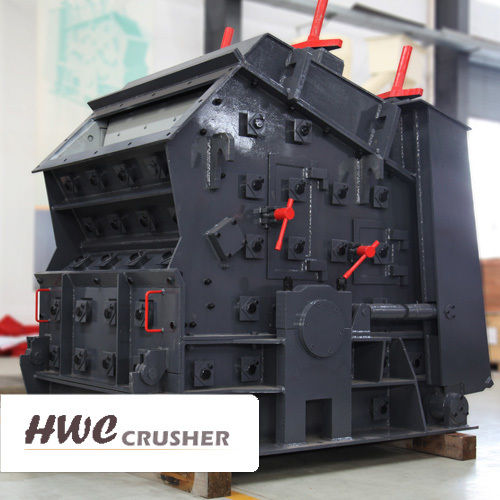

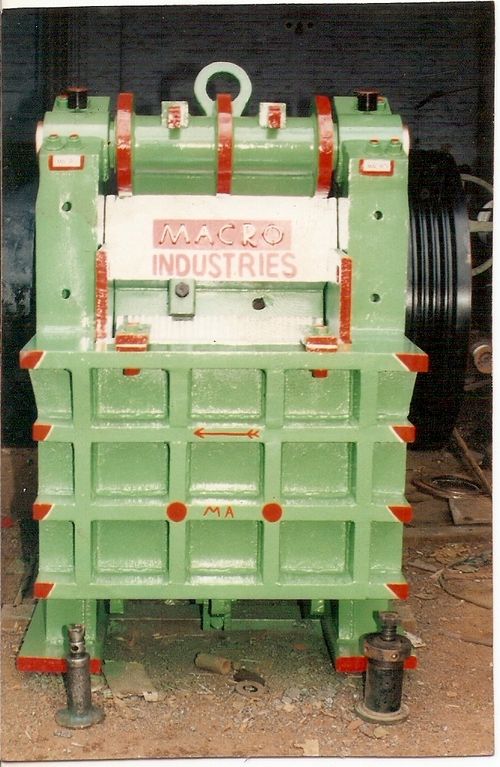

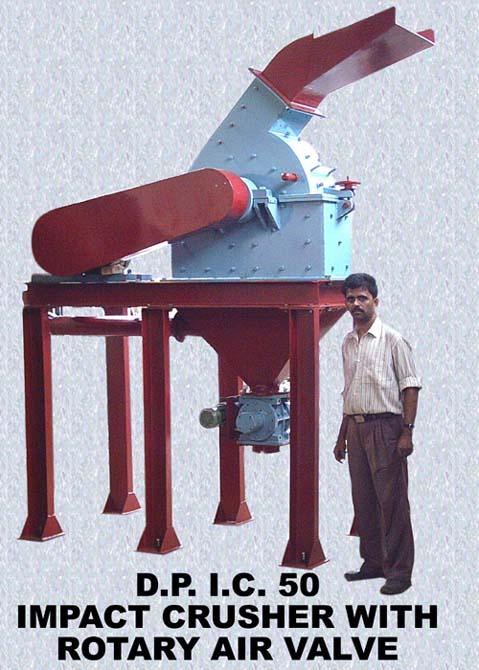

We are a well established organization engaged in manufacturing supplying and exporting premium grade Impact Crusher. These products are widely demanded by mining industries chemical industries and many others owing to their longer service life and excellent performance. We manufacture these products from stainless steel and other components following industry norms and standards. We are able to offer this Impact Crusher in various specifications to meet the requirements of our clients. Other information: Shanghai Shibang series of impact crusher is widely applied in mining transportation energy construction and chemical industry. They are ideal choice for crushing and screening. This crusher features reasonable structure high productivity easy operation and maintenance and safe performance. The most outstanding advantage of this machine is that its finished powder is in good cubic shape and without tensility and cranny.Crusher Features and Benefits: 1. High reduction ratio and crushing efficiency;2. No-board connection; The blow bar with high chrome(high chromed blow bar).3. Impact plate with a special shape.4. Crushed product with cubical shape.5. Easy maintenance and reliable operation.Crusher Working principle:The crusher materials with impact force. When the materials enter the blow bar area they are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor for secondary crush. Then the materials will be shot back to the blow bar again for the third crush. This process repeats until the materials are crushed to the required size and discharged from the lower part of the machine. The size and shape of the finished powder can be changed by adjusting the gap between the impact rack and rotor support. The crusher employs self-weigh security device in its back frame. When other objects enter the impact cavity they will be forced out of the machine by the impact rack in the front and back of the machine. Model Input size(mm) Output size(mm) Capacity (t/h) Power (Kw) Weight (t) PC 400-300 100 15 5-10 11 0.8 PC 600-400 220 15 10-25 22 1.5 PC 800-600 350 15 20-50 55 4.7 PC 800-1000 400 15 20-75 110 This specification is just reference any changes are subject to the crusher products.