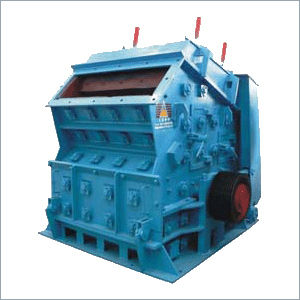

Backed by rich industry expertise we are offering our clients with Hammer Crusher. Our team of expert professionals manufacture these products making use of superior quality stainless steel that is sourced from authorized vendors of market. We manufacture these products keeping in mind the industry laid parameters and norms employing advanced technology and latest machines. The Hammer Crusher made available by us offers high performance and long lasting service. We offer these products in various specifications to meet the requirements of our clients.Hammer Crusher Application: Crusher is suitable for mid-hard and light erosive materials whose pressure resistance strength is no more than 100Mpa and humidity lower than 15% such as coal salt chalk gypsum blocks limestone etc.Hammer Operating Principle: The main working part of crusher is rotors with hammer. The rotors consist of main shaft disk pin shaft and hammers. The motor drives the rotors to rotate quickly in the crushing cavity. Raw materials enter the crusher through the feed opening and are stricken impacted cut and ground by the high-speed hammer to small size. There is a screening plate under the rotor so that materials with size smaller than the screen mesh will be screened out and others are left to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the screening plate. The gap between the rotors and the screening plate can also be adjusted according to different requirement. Model Input size(mm) Output size(mm) Capacity (t/h) Power (Kw) Weight (t) PC 400-300 100 15 5-10 11 0.8 PC 600-400 220 15 10-25 22 1.5 PC 800-600 350 15 20-50 55 4.7 PC 800-1000 400 15 20-75 110 7.9 This specification is just for reference any changes are subject to the crusher products.