Heat Treatment Services By Aptech Engineering Concern

Price:

Get Latest Price

In Stock

Product Specifications

| Process Types | Annealing, Quenching |

| Material Types | Steel Alloys |

| Temperature Range | 500-1200 °C |

| Furnace Type | Various |

| Cooling Methods | Air, Oil, Water |

| Usage | Auto, Aero, Rail industries. Improves metal properties. |

| Quality Standards | ISO 9001 |

| Features | Improved Strength, Enhanced Durability, Increased Hardness, Superior Toughness, Cost-effective |

Product Overview

Key Features

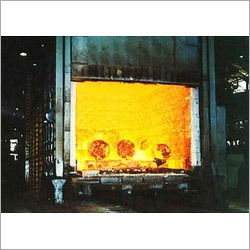

Based at Howrah, West Bengal, India, our firm is engaged in rendering Heat Treatment Services. In order to offer these services, our ingenious professionals work closely with clients to know their exact needs. The offered services are highly demanded in all manufacturing industries such as automobile, aviation, railways, aerospace, tools and dies. These services are best suited for improving the metal mechanical properties such as strength, durability, hardness and toughness. In addition to this, the provided Heat Treatment Services can be availed from us at competitive prices.

Features:

- We use modern tools and equipment to execute these service

- Ensure zero damage of materials during heat treatment

- Suitable for every kind of metal alloy products

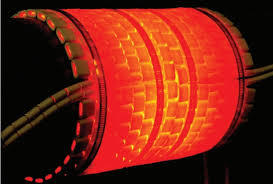

Steels can be heat treated to produce a great variety of microstructures and properties. Generally, heat treatment uses phase transformation during heating and cooling to change a microstructure in a solid state. In heat treatment, the processing is most often entirely thermal and modifies only structure. Thermomechanical treatments, which modify component shape and structure, and thermochemical treatments which modify surface chemistry and structure, are also important processing approaches which fall into the domain of heat treatment.The iron-carbon diagram is the base of heat treatment.

Thermal history of heat treatment operation. According to cooling rate we can distinguish two main heat treatment

operations:

annealing upon slow cooling rate (in air or with a furnace)

quenching upon fast cooling (in oil or in water)

annealing - produces equilibrium structures according to the Fe-Fe3Cn diagram

quenching - gives non-equilibrium structures

Among annealing there are some important heat treatment processes like:

normalising

spheroidising

stress relieving

Company Details

Focusing on a customer-centric approach, APTECH ENGINEERING CONCERN has a pan-India presence and caters to a huge consumer base throughout the country. Get Others from APTECH ENGINEERING CONCERN at Trade India quality-assured services.

Business Type

Service Provider

Establishment

2005

More Product From This seller

Seller Details

Howrah, West Bengal

Accepts only Domestic inquiries

Partner

Mr. Sambhu Samanta

Address

Unit(ii) : "V" Road, Shanpur, (Apanjan Smriti Club), Dasnagar, Howrah, West Bengal, 711105, India

heat treatment services in Howrah

Report incorrect details