Hardening Tempering Services

Price:

Get Latest Price

In Stock

Product Specifications

| Process | Hardening Tempering |

| Materials | Steel alloys |

| Temperature Range | 200-700°C |

| Hardness Range | HRC 40-65 |

| Tolerances | +/- 0.1mm |

| Usage | Improving mechanical properties of various steel components for automotive, industrial, and tooling applications. |

| Standards | IS/ISO |

| Features | Improved Strength, Enhanced Durability, Stress Relief, Customizable, High Precision |

Product Overview

Key Features

We are instrumental in rendering Hardening Tempering Services from our true location Howrah, West Bengal, India. The provided services are offered by our dedicated professionals who use advanced tools and techniques to ensure total clients' satisfaction. These services are used to impart specific mechanical properties to any component. After metal hardening, tempering is performed at low temperature in order to remove stresses and brittleness. Moreover, the provided Hardening Tempering Services can be availed from us at market leading prices.

Features:

- We use modern tools and techniques to execute these services

- Ideal to improve mechanical properties of materials

- Ensure zero damage of materials during execution of this service

Hardening Tempering:

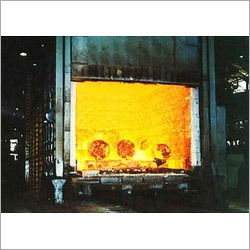

We are offering Hardening Tempering, These are extensively used in a variety of hardening and tempering applications in engineering related industries. Additionally, we custom design these furnaces as per the specific requirements and specifications provided by the customers.

Untempered materialistic steel, while very hard, is too brittle to be useful for most applications. A method for alleviating this problem is called tempering. Most applications require that quenched parts be tempered. Tempering consists of heating steel below the lower critical temperature, (often from 400 to 1105 E F or 205 to 595 E C, depending on the desired results). Higher tempering temperatures, (may be up to 1,300 E F or 700 E C, depending on the alloy and application), are sometimes used to impart further ductility.

Tempering may also be performed on normalized steels. Other methods of tempering consist of quenching to a specific temperature, which is above the martensite start temperature, and then holding it there until pure bainite can form or internal stresses can be relieved.

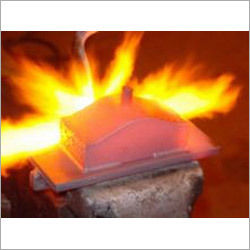

Tempering colors of steel :

Steel that has been freshly ground or polished will form oxide layers when heated. At a very specific temperature, the iron oxide will form a layer with a very specific thickness, causing thin-film interference. This causes colors to appear on the surface of the steel. As temperature is increased, the iron oxide layer grows in thickness, changing the color. These colors, called tempering colors, have been used for centuries to gauge the temperature of the metal. At around 350E F (176E C) the steel will start to take on a very light, yellowish hue. At 400E F (204E C), the steel will become a noticeable light-straw color, and at 440E F (226E C), the color will become dark-straw. At 500E F (260E C), steel will turn brown, while at 540E F (282E C) it will turn purple. At 590E F (310E C) the steel turns a very deep blue, but at 640E F (337E C) it becomes a rather light blue.[

The tempering colors can be used to judge the final properties of the tempered steel. Very hard tool steel is often tempered in the light to dark straw range, whereas spring steel is often tempered to the blue. However, the final hardness of the tempered steel will vary, depending on the composition of the steel. The oxide film will also increase in thickness over time. Therefore, steel that has been held at 400E F for a very long time may turn brown or purple, even though the temperature never exceeded that needed to produce a light straw color. Other factors affecting the final outcome are oil films on the surface and the type of heat source used.

Company Details

Focusing on a customer-centric approach, APTECH ENGINEERING CONCERN has a pan-India presence and caters to a huge consumer base throughout the country. Get Others from APTECH ENGINEERING CONCERN at Trade India quality-assured services.

Business Type

Service Provider

Establishment

2005

More Product From This seller

Seller Details

Howrah, West Bengal

Accepts only Domestic inquiries

Partner

Mr. Sambhu Samanta

Address

Unit(ii) : "V" Road, Shanpur, (Apanjan Smriti Club), Dasnagar, Howrah, West Bengal, 711105, India

Report incorrect details