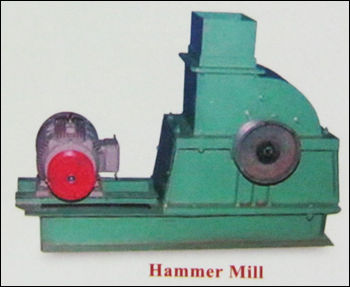

Hammer Mill - Mild Steel Beaters, High-speed Continuous Grinding With Interchangeable Sieves | Robust Design, Dynamic Balance, Easy Accessibility

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Capacity | 250Kg-2Tonnes |

| Motor | 5-30 Hp |

| Mixing Time | 4-6 Mins |

| Rotor | Double Ribbon |

| Discharge | Bottom/Gates |

| Bearings | Heavy Duty |

| Features | Uniform Mixing, High Efficiency, Durable Design, Easy Operation, Versatile Use, Bottom Discharge, Various Capacities, Multiple Motors |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, Spectoms Engineering Pvt. Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Food Processing Machinery in bulk from Spectoms Engineering Pvt. Ltd. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

1974

Working Days

Monday To Sunday

GST NO

24AACCS9401Q1Z0

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AACCS9401Q1Z0

Vadodara, Gujarat

Sr. Sales & Marketing Manager

Mr. Narendra Bhuptani

Address

Plot No. 114, GIDC, Makarpura Industrial Estate, Near Vadsar Railway Crossing, Vadodara, Gujarat, 390010, India

wood hammer mill in Vadodara

Report incorrect details