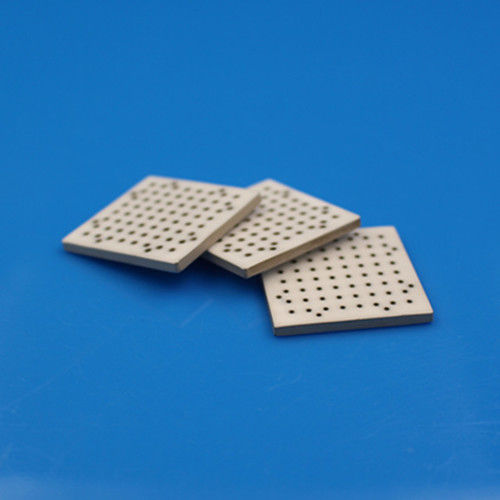

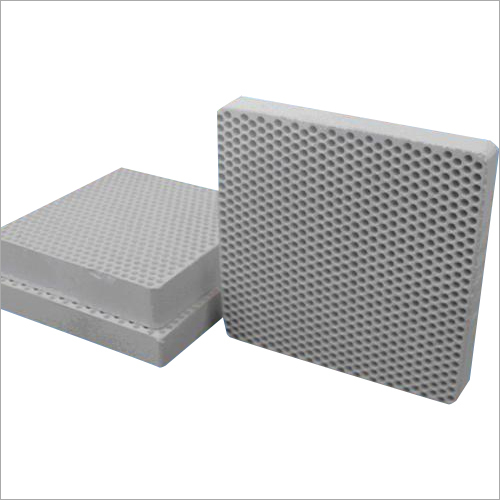

Foundry Molten Metal Filters Ceramic Foam Filter Diameter: 30-600 Millimeter (Mm)

Price Trend: - 50.00 USD ($)

Get Latest Price

Minimum Order Quantity :

2000 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Pressure | 0.8 mpa |

| Length | 40-500 Millimeter (mm) |

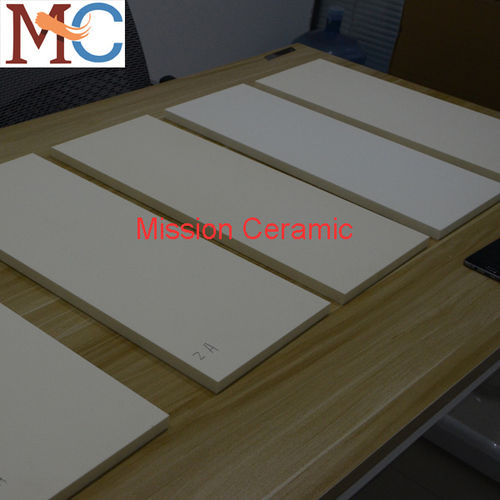

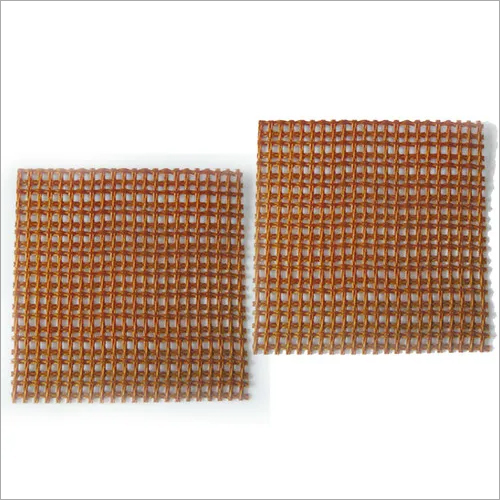

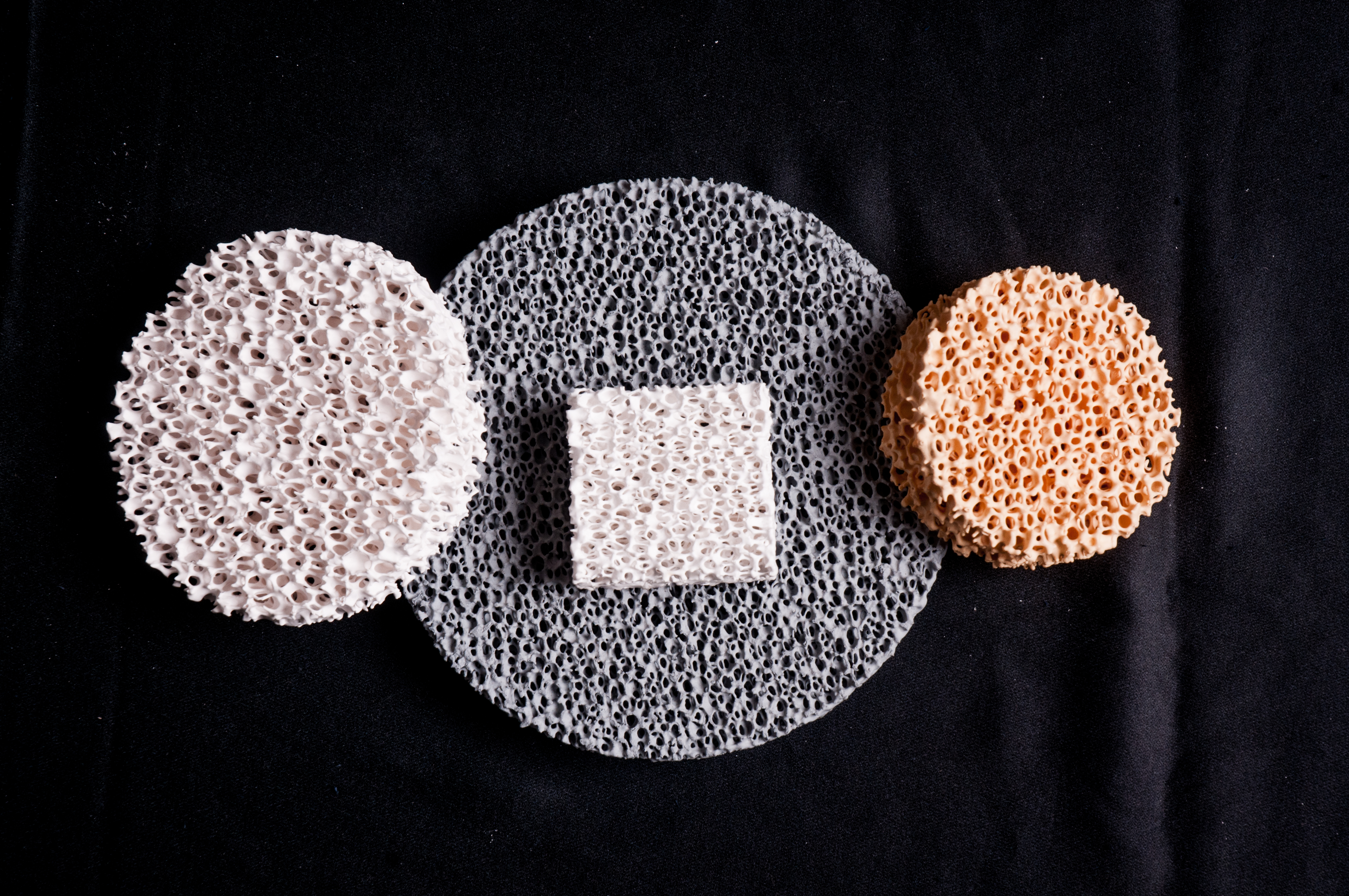

| Color | yellow ,white ,grey |

| Width | 40-500 Millimeter (mm) |

| Product Type | mass production |

| Outlet Diameter | 30-600 Millimeter (mm) |

| Size | 40-500 |

| Pore Size | 10-40ppi |

| Inlet Diameter | 30-600 Millimeter (mm) |

| Filter Rating | 2-45kg/s |

| Weight | 15-6000 Grams (g) |

| Shape | Round ,square ,custom geometric shapes |

| Filter Media | Other |

| Height | 12-50 Millimeter (mm) |

| Usage | Set the filters as close as possible of the casting. |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Other |

| Diameter | 30-600 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Days after Acceptance (DA) |

| Supply Ability | 2000000 Per Year |

| Delivery Time | 10-15 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | carton and pallet |

| Main Export Market(s) | Australia, Eastern Europe, Middle East, Central America, South America, Western Europe, North America, Africa |

| Main Domestic Market | All India |

| Certifications | We can supply ceramic foam filters are as follows: 1.Silicon carbide ( SiC) is used as a distinctive element in the refractory mixture material to make foam filters. Gray in color, foam filter is a strong and durable foam filter, which can be used to purge and filter solution of ductile iron casting, grey iron and other iron casting.2. Zirconia Ceramic Foam Filter is applied to purge and filter solution of steel high temperature metal such as steel alloy stainless steel etc.Typical application of zirconia ceramic foam filter is for in-mold, tundish, pouring cup or baffle-type filtration.3. Alumina Ceramic Foam Filter is applied to purge and filter solution of aluminium and aluminium alloys. White in color alumina foam filter is made from high purity alumina (AI2O3). It has excellent ability to resist high thermal shock while maintaining efficient removal of impurities with continuous and thorough filtration.Advantage of Ceramic Foam Filters1.Simplified and shorten gating system,increasing yield.2.High strength without loose ceramic particles or powder3.Remove tiny slag effectively and purify molten metal.4.Three dimensional connected mesh structure and high porosity5. Well-distributed molten metal and improve performance.6. Quiet laminar flow of molten metal.7.Smaller particles are captured on the filter cake created by the larger particles , finer particles are captured within the pores in the filter.Principle Of Using Filter:AC/AEURAC/ Set the filters as close as possible of the casting.AC/AEURAC/ Use simple gating system without dirt trap ( improve yield).AC/AEURAC/ The working area of filter should be 4AC/AEURA"6 times of the section of chocked flow in gating system to makesure that the pouring speed is not affected.AC/AEURAC/ Select the proper filters according to types of metal and pouring temperature.AC/AEURAC/ The higher porosity, the better filtration. |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

alumina ceramic plate in Cangzhou

Report incorrect details