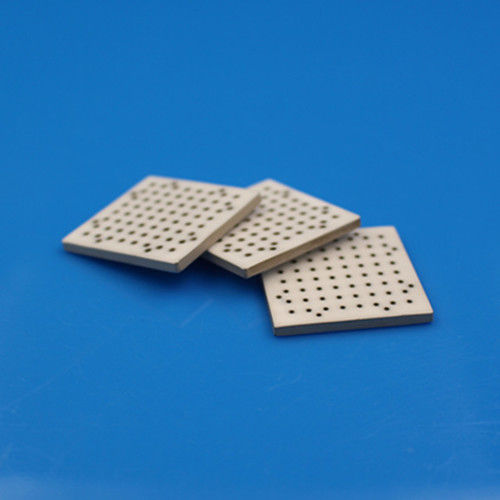

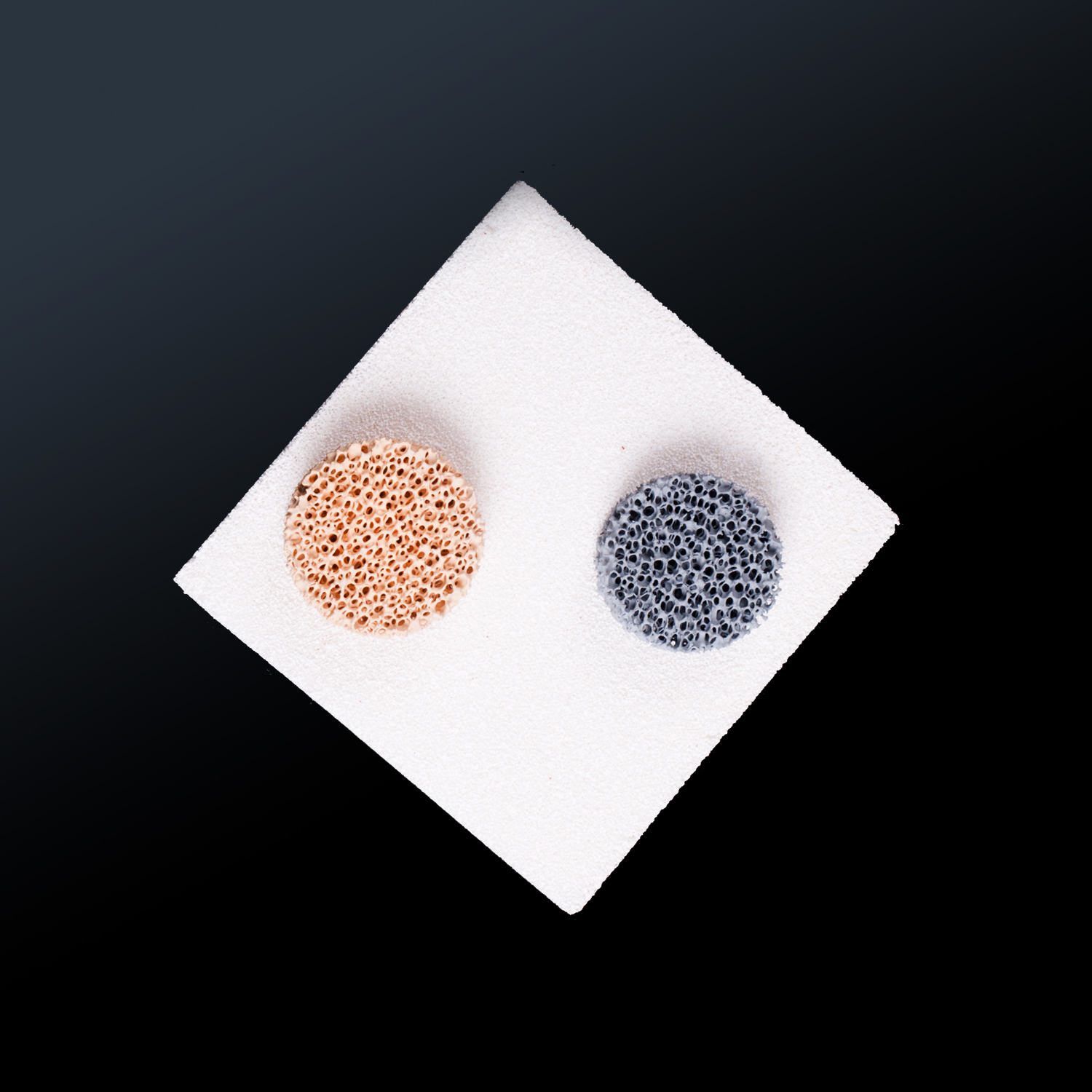

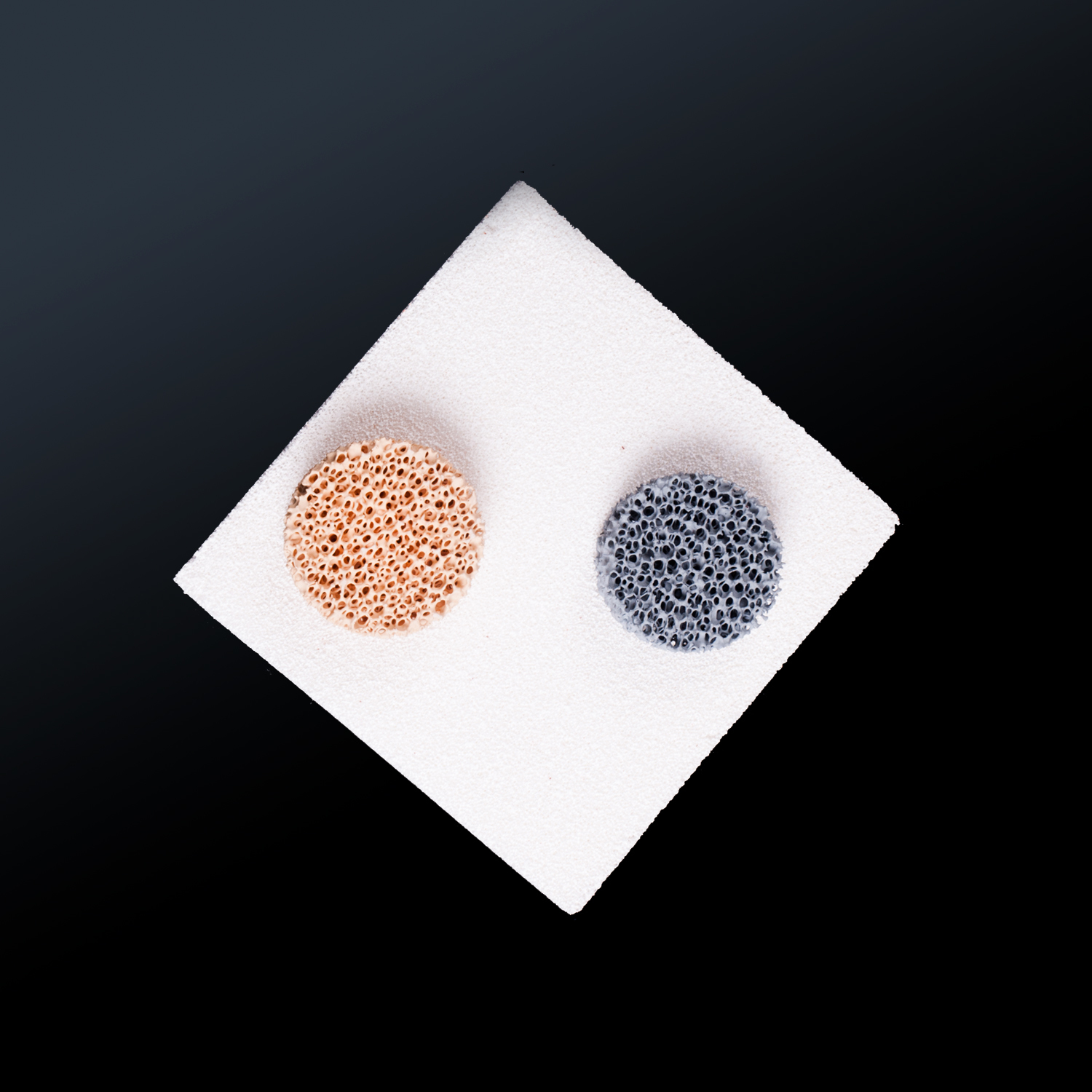

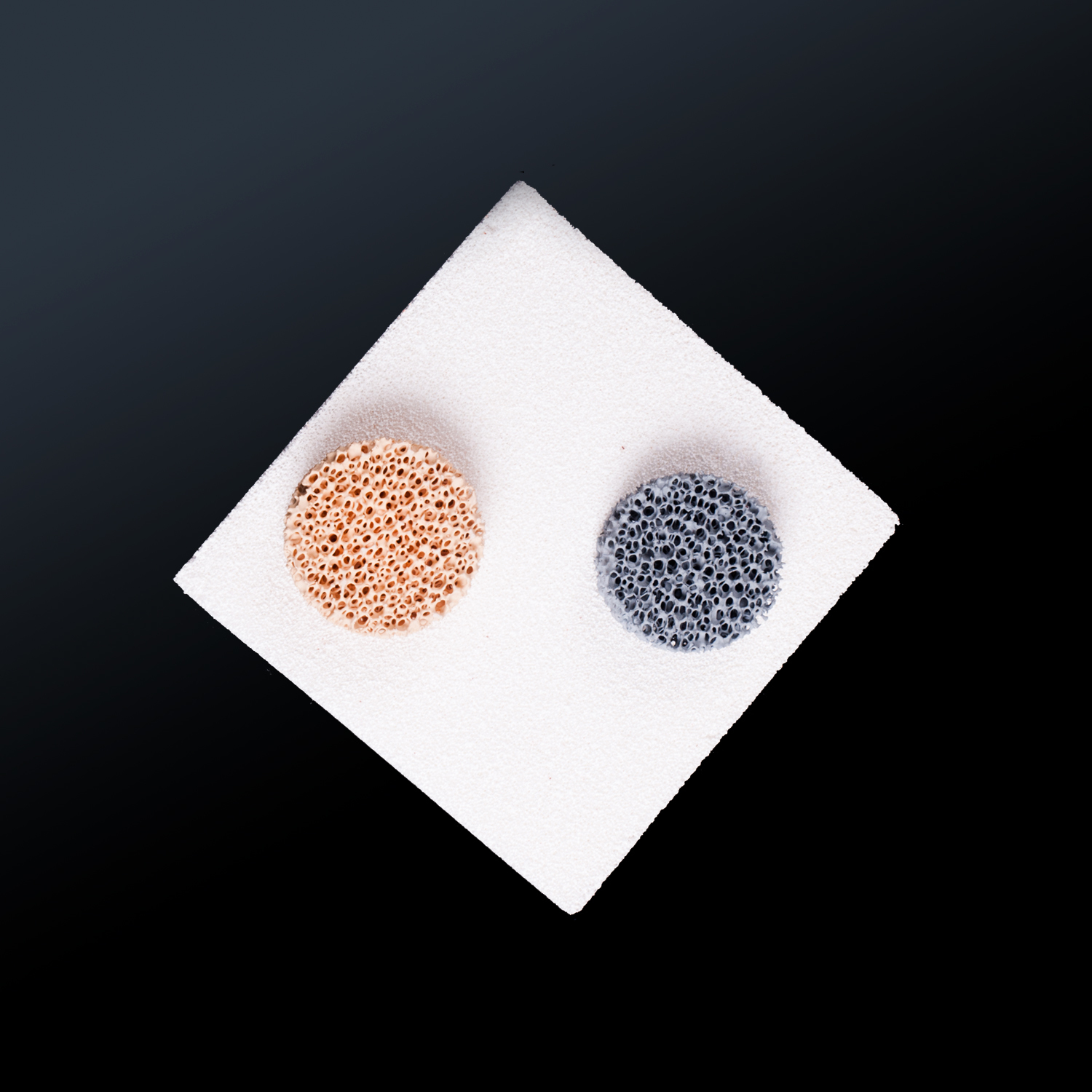

Cearmic Foam Filter For Sand Casting And Investment Diameter: 40-500 Millimeter (Mm)

Price Trend: - 50.00 USD ($)

Get Latest Price

Minimum Order Quantity :

2000 Piece

Brand Name :

Sf

In Stock

Product Specifications

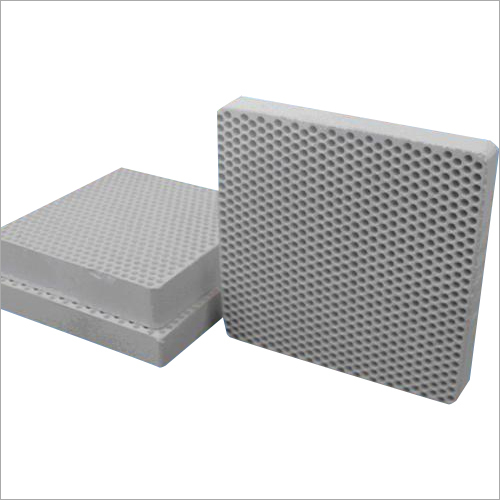

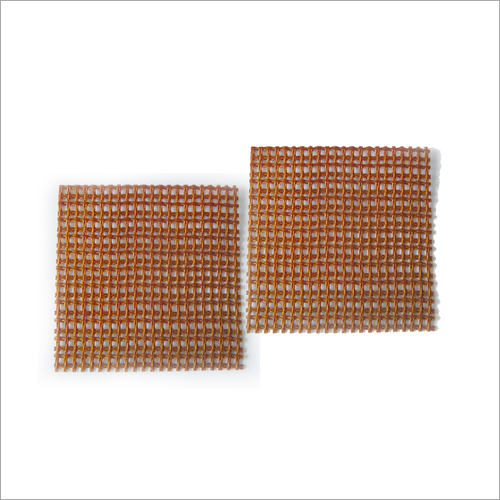

| Shape | Round ,square ,custom geometric shapes |

| Pressure | 0.8 mpa |

| Height | 11-50 Millimeter (mm) |

| Filter Media | Other |

| Size | 40-500 |

| Length | 40-500 Millimeter (mm) |

| Weight | 26-6000 Grams (g) |

| Inlet Diameter | 40-500 Millimeter (mm) |

| Pore Size | 10-40ppi |

| Product Type | mass production |

| Outlet Diameter | 40-500 Millimeter (mm) |

| Filter Rating | 2-45kg/s |

| Usage | Place the filter near the sprue opening |

| Width | 40-500 Millimeter (mm) |

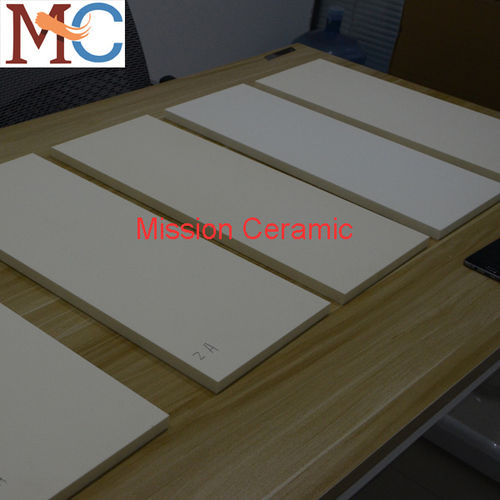

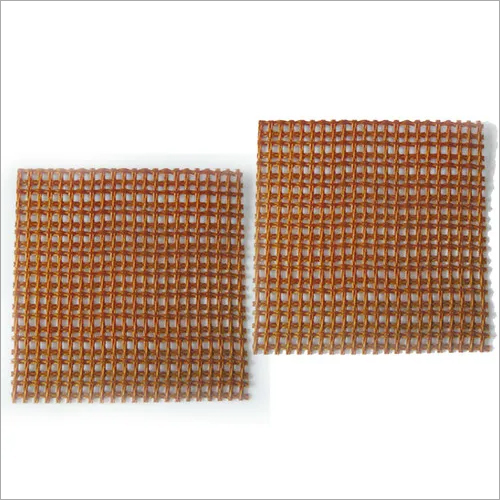

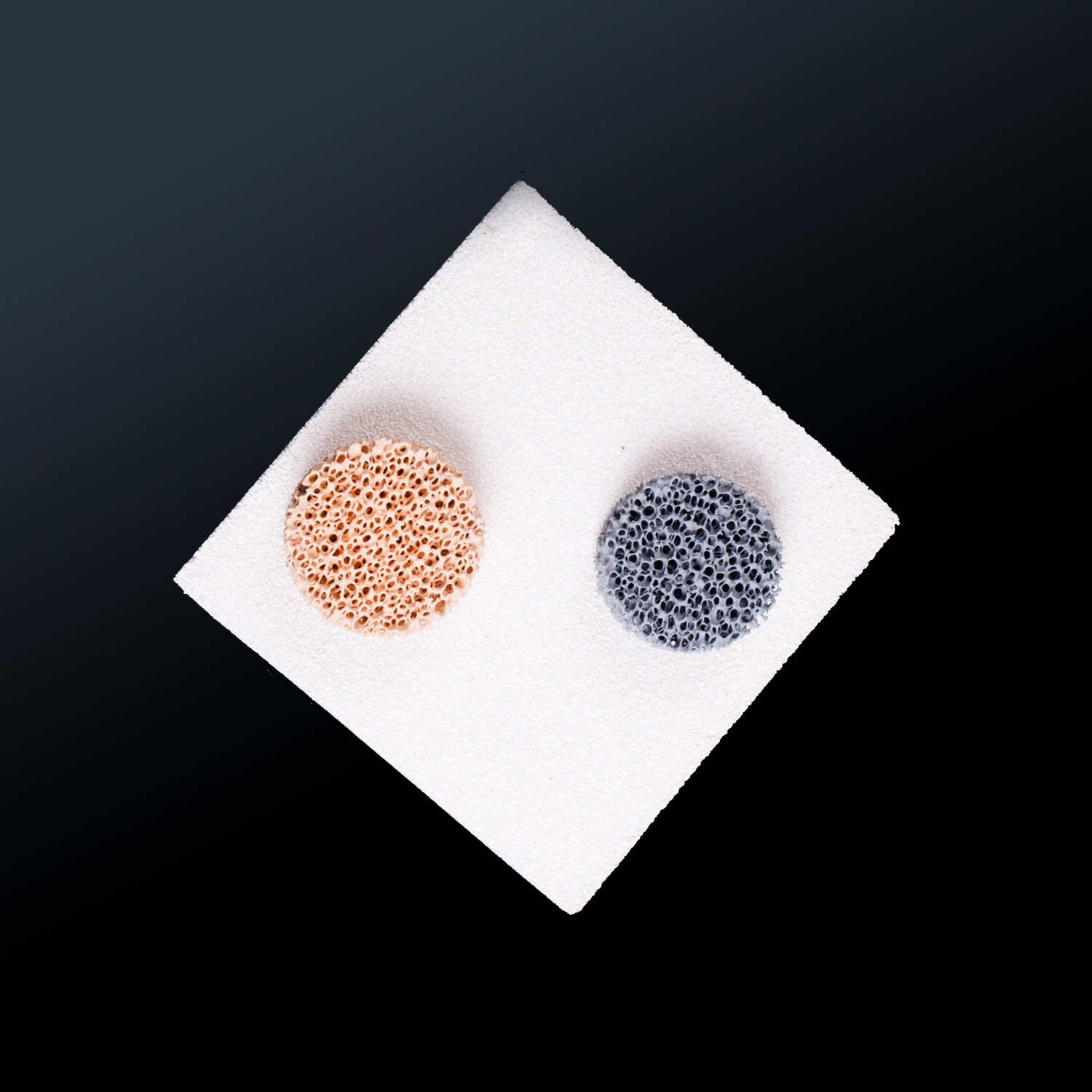

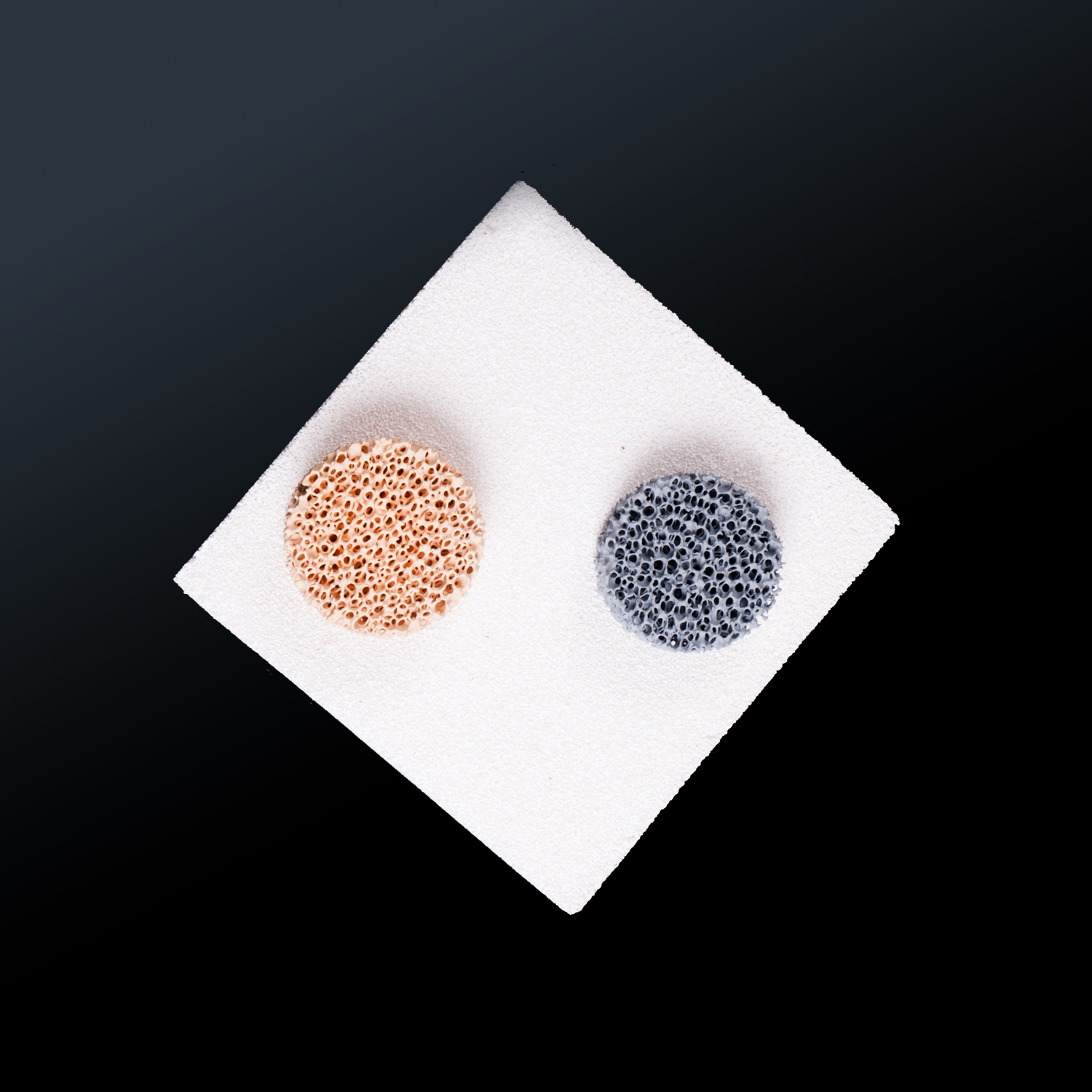

| Color | yellow ,white ,grey |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Double Open End |

| Diameter | 40-500 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Days after Acceptance (DA) |

| Supply Ability | 800000 Per Year |

| Delivery Time | 15-25 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | cartons and pallet |

| Main Export Market(s) | Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Asia, Africa |

| Main Domestic Market | All India |

| Certifications | Physical properties and ApplicationsA A A A A A A A A A Physical Properties For Ceramic Foam FilterMaterial SIC AL ZRColor Grey Black White YellowPore Density 10-40 PPI 10-60 PPI 10-40 PPIPorosity 80%-90% 80%-90% 80%-90%Operating temperature (AoC) a%0$? 1500 a%0$? 1100 a%0$? 1700Bending Strength (MPa) a%0Y=0.8 a%0Y=0.6 a%0Y=1.0Thermal Shock Resistance(times/1100AoC) 6 6 6Applications Ductile cast iron ,Grey iron and other cast iron and nonferrous alloy Aluminum , Aluminum alloys and other non-ferrous alloy. Stainless steel ,Carbon steel and large cast iron .How To Choose Porosity Of Filter:aEURC/ The higher porosity, the better filtration. But too high porosity leads to low speed rate of metal. This is especially important for SG iron.Usually our recommendation are as belowi1/4saEURC/ 10ppiaEUR"for ductile iron, big grey iron, steel casting.aEURC/ 20ppiaEUR"for grey iron, malleable cast-iron,non ferrous alloy casting.aEURC/ 30ppiaEUR"for grey and malleable cast-iron, non ferrous alloy casting.How To Set Filter:The ceramic foam filter can be used in the filtration chamber of a gating system as well as for directpouring on the filter.Filter is usually set above or below the sprue, runner, in pouring cup. |

Product Overview

Key Features

Description

These ceramic foam filters are designed for mould-casting metal.The reticular shape of the foam filter provides a thorough and deep filtration to remove impurities in molten metal stream.Ceramic foam filters have excellent ability to resist high thermal shock while maintaining efficient filtration. They are widely used in sand, investment, shell and permanent molds for both ferrous and non-ferrous alloy filtration operations.Thanks to the mechanism of creation of the filter cake on the inlet filter side and thanks to depth filtration inside the ceramic matrix, these ceramic foam filters are an effective instrument to reach metallurgical purity of molten metal during the process of casting. The filters also calm mould filling, thus preventing creation of undesirable defects in the casting. Thanks to the mechanism of creation of the filter cake on the inlet filter side and thanks to depth filtration inside the ceramic matrix, these ceramic foam filters are an effective instrument to reach metallurgical purity of molten metal during the process of casting. The filters also calm mould filling, thus preventing creation of undesirable defects in the casting.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

alumina ceramic plate in Cangzhou

Report incorrect details