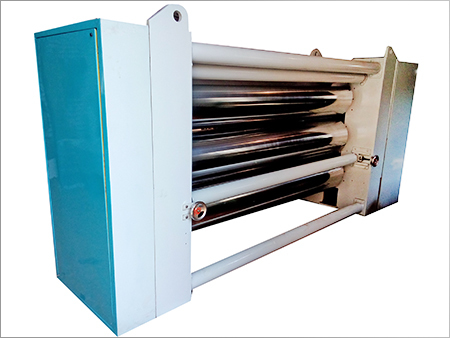

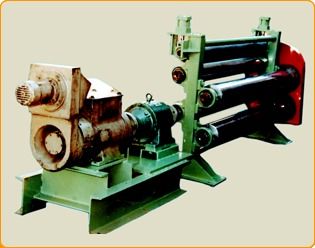

Available In Different Color Factory Price Calender For Paper Making Machine

Price Trend: 100000.00 - 300000.00 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Product Type | Calender for Paper Making Machine |

| General Use | Calender Making |

| FOB Port | QINGDAO |

| Payment Terms | Paypal, Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | All India |

| Certifications | ce |

Product Overview

Key Features

Product Description:

features

1. The 12 rolls are separately driven by 12 DC motors, which allow a wide rang of speed adjustment.

2. The rolls are made of chilled cast iron with vanadium and titanium alloys. The roll face is hard and anti-wear.

3 The rolls are arranged in S form. Roll 1# and roll 4# have roll cambers that can eliminate bending impact on rolls during working process. Thus, it is possible to make products with same thickness along axial direction.

4The transmission system adopts a hard facing gear reducer, which has a compacted structure with higher transmission efficiency, lower noise and longer service life.

5The machine is equipped with emergency device. When an emergent accident occurs, the calendar will be immediately stopped to open the roll space so as to protect the operator and equipment. PLC program controller is used in electric system.

Main Data:

Trimed Sheet Width max 6000mm

Operating Speedmax 1500m/min

Paper Threading Speedoff-line operating:5~15 m/min

online operating: the same as PM and coater

Working Liner Pressuremax350N/mm

Thermal Roll Surface Temp180A C

Number of Calendering Rolls6~12

Top and Bottom Roll Typemulti-zone controllable crown roll

Thermal Roll: shell materialalloy chilled cast iron

Surface HardnessHSD72

surface temp variationA 1A C

Soft Rollroll cover is imported, done by special manufacturers

Calendering roll loading and releasing stylebottom tank loading,and releasing

The loading oil tank is controlled by PLC

Quick releasing and slow releasing

Calendering roll quick releasing time a 0.5s

Calendering roll weight hydraulic compensating systemhydraulic entire or sectional compensation

Thermal roll heating systemElectrical heating, body temp linear control

The heads of soft roll is cooled by blowing

Paper release type( off-line)Constant tension control motor brake to release paper

Under emergency stop, motors generate electricity to brake

Max unreel tension: 0.7~1.5N/mm

Reel change flying connecting speed:20~30m/min

Reel Typeconstant tension control, float loading shaft type( off-line)

Max reel tension:0.7~1.5N/mm

Paper Threadingseparate threading

DriveAC frequency conversion sectional drive

Expect the main drive, the other calendering rolls and some leading rolls, spreader

rolls are equipped with auxiliary drive

Electrical and hydraulic control system

Main drive, reeling and unreeling drive are AC frequency conversion variable-speed

The reeling and unreeling drive are equipped with special operation card and tension

detecting feedback system. Reel and unreel emergency braking tome: 5~10s.

Auxiliary drive s speed and load distribution control.

The oil pressure of bottom roll and controllable crown roll is controlled by PLC.

The oil pressure can be tracked automatically according to the setting linear pressure.

The reel loading linear pressure can be adjusted separately.

Through PLC and field bus, control the machine operation and hydraulic system logic

operation. All the operation can be done through the touching screen.

The operation plant is equipped with buttons, knobs and indicator lights

Inside and outside lifting table

Hydraulic drive, machinery synchronization, equipped with electrical, hydraulic,

machinery

safety device.

CraneUsed for roll changing and maintaining

Our company

Qingdao Jieruixin Co., Ltd., one of the oldest paper companies in China, mainly produce paper making machine and paper coating machine. In addition, we also provide chemicals about paper coating.

Based on more than ten-year experience, we have formed a professional team, and established long-term friendly relationship with our customers. Our products are expoted to different countries around the world, such as Australia, Egypt, Mexico. All in all, as a manufacturer, we try our best to provide the best product and the best service for our customers.

Company Details

Business Type

Exporter, Manufacturer, Supplier, Producer

Employee Count

30

Establishment

2009

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

More Product From This seller

Seller Details

Qingdao, Shandong

Proprietor

Mr Eric Qi

Address

9TH FLOOR, GEMINI TOWER B, 88TH CHUNYANG ROAD, Qingdao, Shandong, 266109, China

calender rolls in Qingdao

Report incorrect details