Electrical Discharge Sawing Machine With Higher Cutting Speed Bladeâ Size: 0.7a A A A A A 1.2(thickness)x25-40(w)x7420(l)

Price: 166800 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | CNC |

| General Use | Sawing machine for Special hard materials, such as high-temperature heat-resistant alloys, high chromium, high nickel alloy, titanium alloy. |

| Material | Steel |

| Capacity | 40 Cubic Meter (m3) |

| Weight (kg) | 15000 Kilograms (kg) |

| Computerized | Yes |

| Automatic | Yes |

| Control System | PLC Control |

| Cutting Speed | 0.1080 sq m/hr |

| Cutting Thickness | 800 Millimeter (mm) |

| Cutting Function | Full Automatic |

| BladeÃÂ Size | 0.7AfA-A,A1/2A,Az1.2(thickness)x25-40(W)x7420(L) |

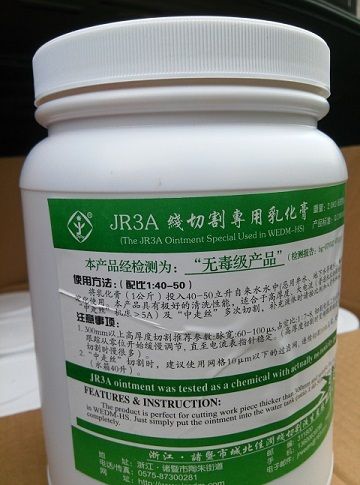

| Cooling System | Other |

| Drive Type | Electric |

| Voltage | 380 Watt (w) |

| Color | Green |

| Warranty | 1 year |

| FOB Port | shanghai |

| Supply Ability | 10 Per Year |

| Delivery Time | 6 Months |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Exporting Wooden cases |

| Main Domestic Market | All India |

Product Overview

Key Features

Benefits you will get with EDS machines:

Benefit A. Saving production time (Max cutting speed: 1800mm2/min)

Benefit B. Saving tool cost (the electrode is cheaper: around 1.2USD/pcs)

Benefit C. Saving material cost (the cutting gap is smaller: 1.5-2mm)

I.The machine characteristics:

(1)The machine utilizing anodic machining principle, cutting special steel that can't be easily cut, such as high-temperature heat-resistant alloys, high chromium, high nickel alloy, titanium alloy. It can also cut steel rail.

(2)The cutting efficiency is high, the maximum cutting speed is 1800mm2/min

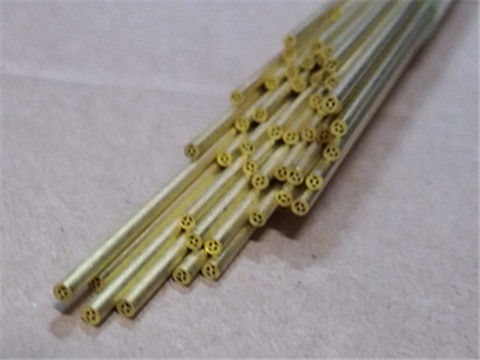

(3)Use steel as the electrode, the cost is rather lower

(4)Cutting gap, 2mm, save precious steel

II. Specification

Model No. : EDS350

Max. cutting diameter : 350mm

Max. workpiece width : 810mm

Max. cutting travel : 400mm

Max. cutting length : Unlimited

Worktable dimensions : 800x2000mm

Worktable moving travel : 800mm

Max cutting speed : 1800mm2/min

Max. worktable load : 2500kg

Electrode size : 0.7 1.2(thickness)x25-40(W)x7420(L)

Cutting gap : 3mm

Electrode Material : Steel

Max. output current : 500A

Controller : German Siemens

Feeding motor :AC servo motor

III. Introdution of Electrical Discharge Sawing machine.

Working theory

The machine utilizing anodic machining principle, cutting special steel that canA AcA A A A t be easily cut, such as high-temperature heat-resistant alloys, high chromium, high nickel alloy, titanium alloy. And the electrode is the mild steel, which is running fast on the pulleys.

The work piece is positioned on the worktable. And the mild steel electrode connects with the plus end of the power supply. And the work piece to the minus end of the electrical power supply. There is a flushing device which can supply sodium silicate solution (the coolant) to the cutting area. The electrical discharging happens continually between the mild steel and the work piece according to the drawing.

Simple description

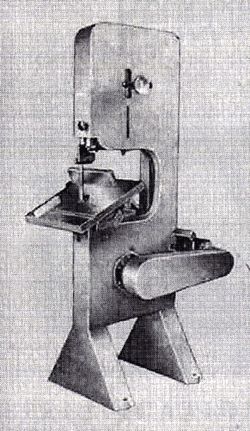

The machine is equipped with the main machine body, working liquid system and controller.

1) The main machine body

The machine is gantry structure which is made up with the worktable parts, moving crossbeam and upright column the motorized electrode, etc.

Worktable

The worktable is used for holding and adjusting the work piece. The worktable moves from point to point or continually, derived by the motor and couple and ball screw on the V guide way of the machine body.

Device of running the belt type steel electrode.

This device has functions of running& guiding and controlling the tension of the belt type electrode steel and also the function of higher power supply feeding, and checking and protection of belt-breaking.

The belt type steel electrode is running on the driving pulley and slave drive ones which are installed on the both holders of two ends of the crossbeam.

The driving pulley is moved by the 3 phases motor and the slave drive pulley by hydraulic pressure. The belt type steel electrode is guided with two guiders in order to make sure the electrode is under good tension condition. And the belt type steel electrode tension can be adjusted by the hydraulic pressure. In case the belt type electrode breaks or the tension is weak, the alarm will appear at once and the machine will stop working too. The power supply feeds through the pulley, installed with the power feed brush, pulley axle and to the belt type steel electrode.

The steel belt electrode is held by four sets of guiders in order to make the electrode running in the same surface of the work piece cross section and make the cutting gap as small as possible. There are flushing mouths on the guiders, which offer the working liquid to the cutting area.

Company Details

Focusing on a customer-centric approach, TECH EDM TRADE CO., LTD has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cutting Machine in bulk from TECH EDM TRADE CO., LTD at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

15

Establishment

2015

Working Days

Monday To Friday

Payment Mode

Cash on Delivery (COD)

Certification

Patents

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Suzhou, Jiangsu

Vp

Mr Bob Li

Address

No. 58 Huajin Road, Suzhou, Jiangsu, 215153, China

sawing machinery in Suzhou

Report incorrect details