Dry Mix Mortar Plant - Cement, Lime & Silica Sand Composition | Automated Mixing & Efficient Packing System, Versatile Applications For Tile Fixing And Waterproofing

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Capacity | Customizable |

| Power | Electric |

| Automation | Robotic |

| Controls | Plc-Based |

| Safety | Cage System |

| Features | Automated Mixing, Precise Dosing, Efficient Packing, Consistent Quality, Customizable Blends, Reduced Labor Costs, Increased Output, Economical Design |

Product Overview

Key Features

Dry Mix Mortars are pre blended in a factory delivered to a site in bags and applied mechanically using special application technology or simply by hand. Dry mix mortars offer a number of advantages such as consistent product quality, customized logistics and planned inventory for the contractor/clients.

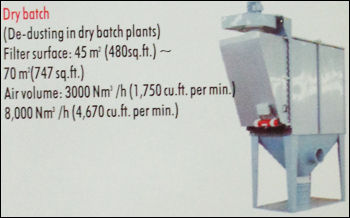

Process: The process of manufacturing Dry Mix Mortars consists of Dosing, Weighing, Mixing and packing. Our plants are simple & economically designed keeping our clients best interests in mind. All materials are formulated using locally available raw materials as for as possible. The main raw materials i.e. cement, lime & silica sand are first dried, screened, weighed and conveyed to storage silos. From the silos each material is fed into the weigh batch hopper above the mixer as per the formulated weights. The material is then emptied in to the mixer. Special additives are added to the mixer by a dosing system and the mixer is then run for 2 minutes. After the mixing process the prepared material is emptied to a hopper of a packing machine. The product is then packed in 25 or 50 kgs bags.

Product for which we offer formulations

1. Tile Glue

2. Repair Mortars.

3. Tile Grout

4. Non- Shrink Grout.

5. Pre Mixed Plaster

6. Rebar Coat.

7. Water Proof Cement.

8. Brick laying Mortar

9. Polymer Mortar

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

Report incorrect details