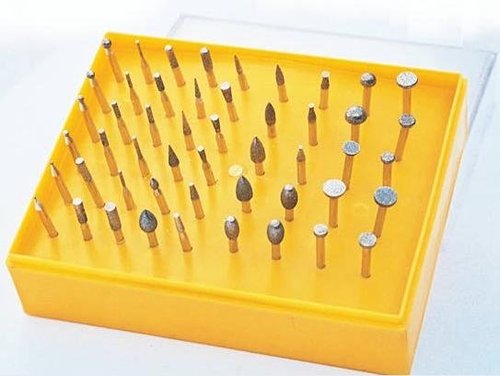

Diamond Mounted Points - Grit Size 80/100 To 200/240, Sizes From 1.0 Mm To 20 Mm | Precision Grinding For Carbides, Glass, Ceramics, And Tough Alloys

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Diamond/Cbn |

| Diameter | 1.0Mm-20Mm |

| Grit Size | 80/100-240/240 |

| Shank Diameter | Variable |

| Length | Variable |

| Shape | Various |

| Application | Internal Grinding |

| Features | Precision Grinding, Durable, Versatile, Efficient, Long-Lasting, High-Performance, Cost-Effective |

Product Overview

Key Features

Diamond mounted points are used for jig, internal grinding and precision grinding of small holes in carbides, glass, ceramics, sapphire and many of the tough, super alloys presently being machined. CBN mounted points are used similarly on tough, high carbon, high chrome steels. These are readily available in sizes varying from 1.0 mm to 20 mm.

Grit Size: 80 / 100 (Rough), 120 / 140 (Medium), 200 / 240 (Fine), or as specified.

Recommended Use:

Low wheel speed is one of the major causes of poor performance in super abrasive products like Diamond or CBN. Wheel loading and heat build-up are common signs of low RPM. The recommended speed for Electroplated Diamond Internal Grinding Wheel is 2100 to 3600 m/min and for Electroplated CBN Wheel is 3600 to 6000 m/min. The suggested feed vary from 0.005mm to 0.05mm depending on the material ground. Coolant should be used wherever possible, but can be used dry successfully.

Internal grinding is arguably the most challenging of all grinding applications. In no other type of grinding can the entire range of parameters change from one job to the next. Therefore, it is necessary to consider the specifics of each job individually in order to arrive at the wheel best suited for the job.

In order to maximize performance capabilities and profit margins, choosing the correct wheel for a job is extremely important. Unfortunately, this isn't always the easiest decision to make, as many factors play into such a selection. One must consider material to be ground, size of area to be ground, amount of stock to be removed, finish desired, machine capabilities and a number of other factors.

The following is a general outline of the steps which would lead to the selection of the correct wheel for you:

MATERIAL TO BE GROUND

The deciding factor in which Super abrasive to use lies in whether the material to be ground is ferrous (containing iron) or non-ferrous (carbide, glass, ceramic, etc.). Generally, ferrous materials are ground with CBN and non-ferrous materials are ground with diamond.

HOLE SIZE (AREA TO BE GROUND)

In the case of Super abrasive internal grinding, the wheel is generally 40-60% the size of the hole diameter being ground. Larger diameter holes will require a lower percentage, while smaller holes require a greater percentage (see illustrations). The depth of the hole determines the length of the abrasive as well as the undercut (if required) and the overall length of the mandrel (abrasive length + shank length). The other basic variable to be considered in wheel size is shank diameter, and that is determined by the size of the Collete, or simply by choosing the stiffest shank that will fit reasonably with the wheel diameter. In most cases, if the wheel diameter is smaller or equivalent in size to the shank diameter, an undercut may be required behind the wheel for needed clearance (see Illustration 1).

MACHINE SPECIFICATIONS

Required information includes type of machine (jig grinder, I.D. grinder, machine center, etc.) and spindle r.p.m. capabilities. Machines should have a rigid wheel head spindle, rigid bearings in the headstock spindle, and feed increments of .0001" or smaller. Industry-wide, these machines have a wide variety of r.p.m. ranges, and Va-run Udyog has addressed this with the development of a variety of bonding systems which would maximize performance on any machine. Using spindle speed and the wheel diameter one can determine the surface feet per minute (SFPM) for a particular job, which will lead to the next step.

BOND SELECTION

With the correct SF PM figure at hand, the correct bond may be chosen, a general rule to follow in bond selection by cutting surface feet per minute is as follows:

| BOND | SF PM |

| VM (Standard) Vitreous Metal | 1,000-3,000 |

COOLANT

Proper coolant will enhance the performance of the wheel as well as the finish in cases of heavy stock removal or fine finish requirements. Diamond wheels require a synthetic coolant, while CBN wheels use oil or water-soluble oil

GRIT SIZE SELECTION

Finally, the grit of the wheel can be determined. This is accomplished by considering the median between stock removal and finish desired. A coarse grit will be more aggressive, but will consequently leave a rough finish, while the opposite is true for a finer grit. Varun Udyog has experience working with grits as coarse as 30/40 and as fine as

20,000, so arriving at a figure to suit the need of individual customers is a commonplace operation.

CONCENTRATION

Concentration refers to the ratio of the volume of Super abrasive to the volume of bond in a grinding tool. Although there is some variation throughout the industry, generally accepted standards are as follows:

| CONCENTRATION | ABRASIVE BY VOLUME |

| 50 | 12.5% |

| 100 | 25% |

| 150 | 37.5% |

Low concentration provides more aggressive cutting, coarser finish and potentially higher wheel wear while high concentration provides less aggressive cutting, finer finish and lower wheel wear.

The following table gives recommendations regarding materials to be ground either with Diamond or with CBN Wheels.

| | DIAMOND | CBN |

| TC, Presented | 0 | |

| TC / Steel Combinations | 0 | |

| Wear Resistant Coatings | 0 | |

| High Alloy Steels | | 0 |

| High Speed Tools Steels | | 0 |

| Hot and Cold Working Steels | | 0 |

| Case Hardening Steels | | 0 |

| Tempering Steels | | 0 |

| Ball Bearing Steels | | 0 |

| Spring Steels | | 0 |

| Cast Iron | 0 | 0 |

| Glass, Quartz, Precious and Semi Precious Stones | 0 | |

| Alumina and Ceramics | 0 | |

| Porcelain, Stoneware, Steatite | 0 | |

| Germanium, Silicon, Fer-rites | 0 | |

| Graphite | 0 | |

| Natural and Artificial stone, Refractories | 0 | |

| Duro Plastics, Glass Fiber Reinforced Plastics | 0 | |

| Bonded SiC or Aluminum Oxide Abrasives | 0 | |

Company Details

Focusing on a customer-centric approach, VARUN UDYOG has a pan-India presence and caters to a huge consumer base throughout the country. Buy Diamond Cutting Tools in bulk from VARUN UDYOG at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

1993

Working Days

Monday To Sunday

GST NO

27AAFPG3491C1ZZ

Payment Mode

Cheque/DD, Wallet & UPI

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAFPG3491C1ZZ

Navi Mumbai, Maharashtra

Proprietor

Mr Varun Gupta

Address

C-337, Pawane, MIDC TTC Indl Area, Navi Mumbai, Maharashtra, 400703, India

diamond mounted points in Navi Mumbai

Report incorrect details