Continuous Fermenting Machine - Stainless Steel, Modular Design Dimensions, Low Power Compact Shaft-mounted Drive | Individual Air Control, Easy Cleaning, Uniform Results, Two-stage Process, Magic Mesh

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Variable |

| Mesh Type | Magic Mesh |

| Power | Low |

| Drive | Compact Shaft-Mounted |

| Air Control | Modular Dampers |

| Capacity | Modular Enhancement |

| Features | Even Fermentation, High Output, Modular Design, Easy Cleaning, Improved Hygiene, Uniform Results, Space Saving, Low Power, Two-Stage Process, Individual Air Control |

Product Overview

Key Features

THE NEW -AGE CFM

TIG's Matrix PVB Magic Mesh CFM is the answer to all fermentation needs. It's individuals air control design, imported Magic Mesh and Centralised Control Console ensure the best possible hygiene, high output and uniform fermentation. The 'modular' concept allows for enhancement in capacity. The Matrix is supplied with individual modular dampers for complete flexibility in air control. Humidified air from a specillly designed Mist Chamber complete the system.

TWO STAGE MATRIX CFM

The concept of two stage fermentation has gained wide popularity in the Tea Industry due to better results. The orientation of two stages can be arranged in different ways to suit individual reqirement and preference. The first stage and the second stage have independent fermentation time setting arrangement and provide much more flexibility to the user to achieve desired results. The bed thickness can also be varied in two stages depending on fermenting needs. The Dhool dropping from the first stage to second stage allows better aeration & the cascading effect avoids caking of the tea bed, resulting in more uniform fermentation across the width and length of the machine. The use of upturner and /or plough is eliminated, resulting in better tea character.

Salient Features & Advantages:

- Magic Mesh:

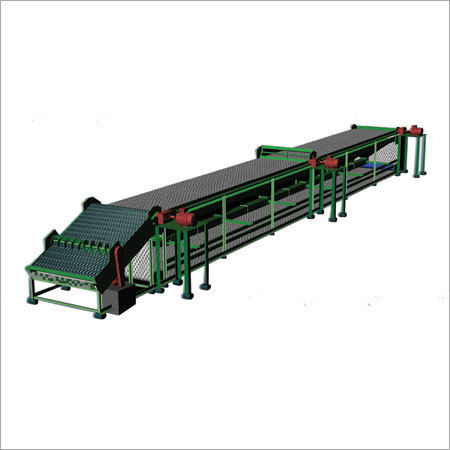

The heart of TIG's Matrix PVB CFM is the specially imported Magic Mesh with 46% open area. This Magic Mesh provides several advantages: Open area nearly 80% more than SS trays/belts, which ensures even fermentation across the tea bed, improved cup characteristics and infusions. Availability of the Magic Mesh in up to 10ft,width,which is space saving and enables wider machines and shorter lengths. Specially designed idlers and SS skid plates are provided to support the Magic Mesh conveyor. - Modular Air Control Arrangement:

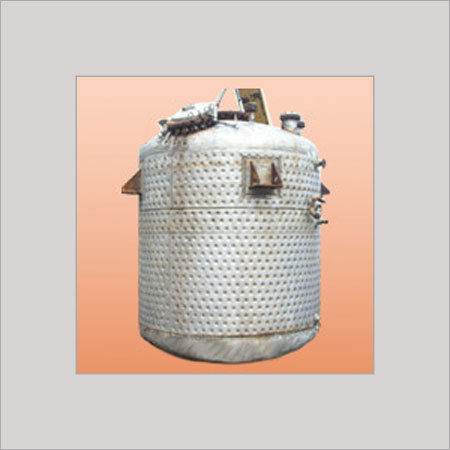

Each module is fitted with an Individual Damper to draw only the required quantum of humidified air. The common duct runs parellel to the machine and specially designed air chambers with perforated pressure plates are used to feed humidified air to each module. This design eliminates accumulation of tea in ducts. - Construction:

The machine is designed for maintaining the highest standards of hygiene and uses stainless steel Aerodynamic Hoppers. All parts of the machine coming in contact with tea are also made of stainless steel. The heavy duty rectangular tube section framework adds to the strength of the machine. The matrix is low in height making it convenient to monitor and easy to clean. - Stainless Steel Air Ducts:

Circular SS Tapered Air supply Ducts are provided to maintain uniform air pressure throughout the length of the machine. The circular design improves hygiene and air flow into the machine. - Compact Shaft-Mounted Drive:

This advanced mechanism has following benefits : - 1. Eliminates the needs for a drive pedestal.

- 2. No obstruction in floor space.

- 3. Low power consumption.

- 4. Longer,trouble-free life.

- 5. No V-Belts used.

- Centralised Operating Control Console:

This console has an in-built AC Variable Speed Drive, Temperature Inductors, busbar arrangement with MCBs, Ammeter, Voltmeters and push button motor on/off switches. These are all enclosed in dust proof, powder coated, two-door panel. - Humidfication:

For continuous supply of fresh humid air into each module, a Centrifugal Blower is connected to the Mist Chamber or Y-Duct to suit the site conditions. Two humidifiers are provided with the humidification system. - Feed Conveyor:

A full width(10'/8'/6'/4') PVC Feed Conveyor with Spiral Spreader ensures regulated feed and even spreading of 'dhool' on the machine. An extended belt can be provided to reduce feed height and enable direct feed from the CTC or Googhie. - Nylon Cleaning Brush:

Unique simple detachable design which allows changing and cleaning brush even when machine is in use.

OPTIONAL ACCESSORIES:

- Oscillating Conveyor

- Effective Upturner

- Discharge Conveyors

- Bail Breakers

Specifications:

| Matrix PVB | Machine Widths : 10',8',6' & 4' | ||||

| Overall length W/O Feed Conveyor | 10076 | 12100 | 14124 | 16148 | 18172 |

| Overall length with Feed Conveyor Extn. | 13426 | 15450 | 17474 | 19498 | 21522 |

| Std. | 11460 | 13484 | 15508 | 17532 | 19556 |

| Overall Width | 3590 | 3590 | 3590 | 3590 | 3590 |

| Feeding height of Feed Conveyor Extn. | 590 | 590 | 590 | 590 | 590 |

| Std. | 1225 | 1225 | 1225 | 1225 | 1225 |

| Discharge Height from Floor Level | 700 | 700 | 37 mins to 700 mins | 700 | 700 |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1949

Working Days

Monday To Sunday

GST NO

19AAACT8460G1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 19AAACT8460G1Z4

Kolkata, West Bengal

Executive Chairman

Mr. Sajjan Bagaria

Address

11, Jassal House, 4-A, Auckland Square, Kolkata, West Bengal, 700017, India

fermentation equipment in Kolkata

Report incorrect details