CNC Machined Components

(4541 products)Cnc Miling - Color: Sliver

MOQ1 Piece/Pieces

ColorSliver

UsageIndustrial

SizeStandard

MaterialMetal

SurfacePowder Coated

UseIndustrial

Brown Cnc Machine Telescopic Cover

Price Trend: 1000.00 - 10000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeCNC Machine Telescopic Cover

Colorbrown

MaterialStainless Steel

CNCYes

SurfacePolishing

UseIndustrial

Adtech Cnc Punching Controller - Application: Industrial

Price: 90000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeAdtech CNC Punching Controller

ColorBlack

UsageIndustrial

ShapeRectangle

MaterialPLASTIC

ApplicationIndustrial

White Led Cnc Machine Light

Price: 1500 INR/Unit

MOQ10 Unit/Units

ShapeRectangle

ColorWhite

Light ColorWhite

Product TypeMachine Light

BaseCoated

Input Voltage230 Volt (V)

CNC Router Collet - Steel Material, ER Type, 0.001mm Accuracy | HRC 45-50 Hardness, Ideal for Precision CNC Routing

Product DescriptionWe are counted among the leading manufacturer, exporter and supplier a huge gamut of CNC Router Collet in Ahmedabad, Gujarat, India. Offered CNC Router Collet comply with the latest trends of the market as these are manufactured by our experts with the assistance of latest machinery available at our

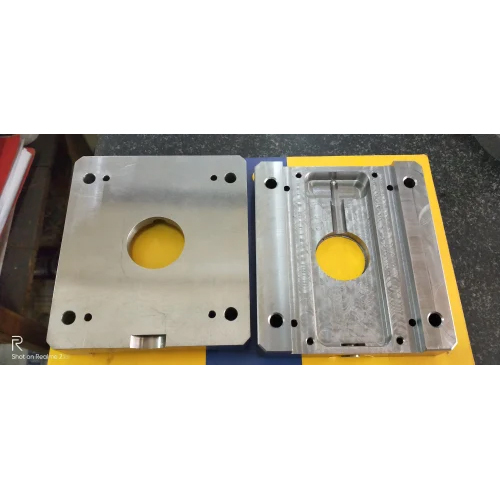

CNC Machined Components - Precision-engineered Aluminum Alloy, Custom Sizes Available , High Tolerance and Durability

Price Trend: 1000.00 - 10000.00 INR/Piece

MOQ1 Piece/Pieces

MethodTurning milling or drilling processes

AccuracyHigh accuracy

WeightLightweight to medium-weight components depending on material

CoatingNone or standard protective coating

Load CapacityDependent on application

Spindle SpeedConfigured speed as needed for precision machining

Black Electric Cnc Germany Controller

Price: 200000 INR/Unit

MOQ1 Unit/Units

ColorBlack

Product TypeElectric CNC Germany Controller

SizeDifferent Available

UsageIndustrial

MaterialABS

CNCYes

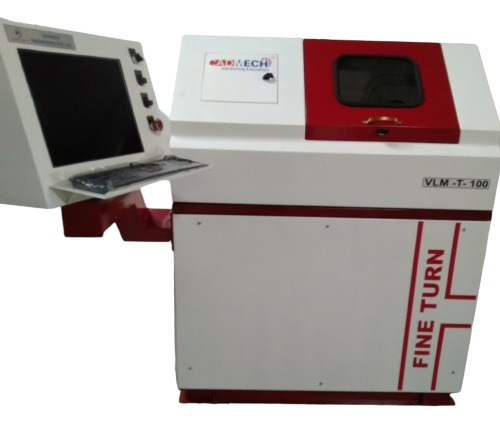

CNC Lathe Trainer Kit - 92x94x67 Inches , White and Red Finish, 1000 Kg Weight, Rugged Design with Advanced Stepper Motors and Emergency Safety Features

Price: 600000.00 INR/Unit

MOQ1 Unit/Units

UsageFor Training

Height92 Inch (in)

Weight1000 Kilograms (kg)

Width67 Inch (in)

Product TypeCNC Lathe Trainer Kit

ColorWhite and Red

Round Precision Turned Components

Product DescriptionBrand - Zenith\015\012Finish - Anodizing, Zinc-Plated\015\012Process - CNC machining\015\012Shape - Round\015\012Material - Brass

Ruggedly Constructed Heavy Duty Cnc Tools

ColorMulti Color

ShapeMultiple

Product TypeCnc Tools

SizeAll

UseWorkshop

ApplicationIndustrial

White Megmeet Gk Series Controller For Imm Operations

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

Size470x260x50 Mm

Product TypeMegmeet Gk Series Controller For Imm Operations

UsageIndustrial

ColorWhite

ShapeRectangle

Durga Hydraulics

Delhi

Trusted Seller

Trusted Seller3 Years

3x1x3 Inches Galvanized Mild Steel CNC Soft Jaw - Mild Steel Material, Silver Color, 500 Grams Weight | Ideal for Precise Fixture During Machining

Price: 370 INR/Set

MOQ200 Set/Sets

Width1 Inch (in)

Size3x1x3 Inches

Product TypeCNC Soft Jaw

UsageIndustrial

Height3 Inch (in)

Weight500 Grams (g)

Ve To Clamping Systems Private Limited

Faridabad

Trusted Seller

Trusted Seller7 Years

Universal Rotary Table

Price Trend: 34000.00 - 115000.00 INR/Set

MOQ1 Set/Sets

Delivery Time1 Week

Main Domestic MarketAll India

Starcut (65 105) Manual Plasma Cutting Machine - Color: Blue And White

Price: 195000 INR/Piece

MOQ1 Piece/Pieces

Product TypeManual Plasma Cutting Machine

UsageIndustrial

ColorBlue And White

SizeStandard

UseIndustrial

ApplicationPlasma Cutting Machine

Cnc Busbar Machine In Bengaluru Noel Machinery, Material: Copper and Aluminium

Product DescriptionCnc Busbar Machine In Bengaluru Noel Machinery

Precision Turned Components - Application: Industrial

Price: 1000 INR/Piece

MOQ100 Piece/Pieces

Product TypePrecision Turned Components

ShapeRound

ColorGray

MaterialSS

SurfacePolishing

ApplicationIndustrial

Golden Cnc Turning Parts

MOQ10000 Piece/Pieces

UsageFor Electronic Use

FinishPolished

TypeCNC Turning Parts

MaterialBrass

Surface TreatmentYes

CNC MachiningYes

CNC Precision Turned Components - Stainless Steel, Customized Size, Silver Color | Chromium Surface Finish, Corrosion Resistant, Ideal for Industrial Applications

Price: 400 INR/Piece

MOQ100 Piece/Pieces

Weight100 Grams (g)

ShapeRound

CoatingZinc, Anodized, Chrome Plating, ENT

UsageIndustrial

SizeAs per required

ColorSilver

Reliable Cnc Tooling

Payment TermsCash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA)

Delivery Time13 Days

Sample PolicyContact us for information regarding our sample policy

Tools Unlimited

Mumbai

Trusted Seller

Trusted Seller12 Years

Precision Machined Components - Stainless Steel & Steel , Silver Color, 0.1 to 100 Kilograms weight, Polished Surface Finishing, Industrial Usage, Structural & Dimensional Precision

Price Trend: 10-1000 INR/Piece

MOQ500 Piece/Pieces

UsageIndustrial

Product TypeCNC Components

ColorSilver

MaterialSteel

Surface FinishingPolishing

UseIndustrial

Harshvijay Exim Opc Private Limited

Ahmedabad

Premium Seller

Premium Seller7 Years

CNC Press Brake Machine - Aluminium, 5.5 kW Power | Automatic and Semi-Automatic Operating Modes

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

Main Domestic MarketAll India

Precision Turned Threaded Components Application: Industrial

Price Trend: 3.00 - 5.00 INR/Piece

MOQ10000 Piece/Pieces

LengthCustomize Millimeter (mm)

Product TypeComponents

ColorSilver

SizeCustomize

MaterialFree Cutting

SurfacePolishing

CNC Lathe Chuck Hard Jaw - EN8 Mild Steel, 8 Inch Chuck Diameter, Silver Color | Ideal for Holding Rotating Workpieces

Price: 400 INR/Piece

MOQ1000 Piece/Pieces

UsageIt Is Used To Hold A Rotating Workpiece

ColorSilver

Product TypeCNC Lathe Chuck Hard Jaw

MaterialMild Steel

UseIt Is Used To Hold A Rotating Workpiece

Ruggedly Constructed Automatic CNC Machine

MOQ1 Unit/Units

Product TypeAutomatic CNC Machine

ColorBlue, White

ApplicationIndustrial

Cnc Machining Components Application: Industrial

MOQ1 , Unit/Units

Product TypeCNC Machining Components

ShapeRound

MaterialMild Steel

SurfacePolishing

ApplicationIndustrial

CNC Machined Components - Metal, Standard Size, Silver Finish | Precision Parts for Industrial Applications, Ideal for Aerospace, Automotive, Medical, Electronics Industries

Price: 30000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

SizeStandard

UsageIndustrial

Product TypeCnc Machined Components

MaterialMetal

SurfacePowder Coated

Latest From Cnc Machined Components

Precision CNC Machined Components

By:

Vinkat Engineers Pvt. Ltd.

Precision CNC Machined Components

By:

Mooto Precision Tools

Explore More Cities

Ready To Ship Cnc Machined Components

Overview of CNC Machined Components

CNC stands for Computer Numerical Control. These machines have computerised controls for operating and manipulating machine tools throughout the manufacturing process. CNC machines are widely utilised in a variety of industries, including aerospace, automotive, electronics, and medical because they can produce high-precision components with complex geometries. CNC machined components are basically parts or goods made utilising CNC machining processes. These parts are often constructed from a variety of materials, including composites, metals (such as titanium, steel, brass, and aluminium), and polymers.

CNC Machined Components | Definition & Functions

Computer-controlled machines known as CNC machines are used to create parts or pieces. These are also known as CNC machined components or Computer Numerical Control machined components. These tools can precisely cut, shape, drill, and finish a variety of materials, including composites, metal, plastic, wood, and wood-plastic composites. A very flexible and effective manufacturing technique, CNC machining is utilised extensively in a variety of sectors, including the automotive, aerospace, electronics, and medical fields.

Applications of these CNC machined components are as follows:

Precision Machining: CNC machines employ computer-aided design (CAD) files and specialised software to precisely and consistently control the cutting tools and movements. This makes it possible to produce complicated and sophisticated shapes that are challenging to produce with manual machining techniques.

Production and prototype: CNC machining is frequently utilised for both large-scale production and prototype. It provides a practical method for making affordable functioning prototypes so that concepts can be tested and improved before going into mass production. Additionally, identical components can be produced in bulk using CNC machines, ensuring uniformity and quality.

Surface Finishing: To acquire the appropriate surface polish, CNC machined components can go through additional processes. Sanding, polishing, grinding, and coating are some of these procedures. Engraving and embossing tasks can also be completed by CNC machines to add aesthetic or practical elements to the components.

Assembly and Integration: CNC machined components are frequently made to integrate with or fit into other components of a bigger assembly. CNC machining possesses high accuracy and dimensional consistency which guarantee precise fit and alignment.

Different Types of CNC Machined Components

CNC Turned Components: These components include shafts, pins, and threaded parts that are manufactured using a CNC lathe that rotates the workpiece as a cutting tool removes material to mould it into the desired shape.

CNC Milled Components: These tools are used to manufacture milled components, which are used to remove material from workpieces by moving the cutting tool in a variety of directions such as brackets, enclosures, and mould cavities.

CNC Drilled Components: Revolving cutting tools are used in the process of making holes in a workpiece. These are capable of precisely positioning and drilling holes of different diameters and depths.

CNC Swiss Machined Components: Swiss machining is a specialised form of CNC machining that is excellent at creating small, very precise components. These are ideal for precision instruments, medical equipment, and electronics.

CNC Laser Cut Components: Laser cutting uses a strong laser beam to pierce a variety of materials, including wood, plastic, and metal.

CNC EDM Parts: Electrical discharge machining is a technique for removing material from a workpiece by using electrical sparks. It is perfect for shaping complicated designs that are difficult to produce with conventional cutting tools and for milling hard materials.

CNC Wire Cut Components: Wire EDM makes precise cuts in complex designs using a thin, electrically charged wire.

Functions of CNC Machined Components

Manufacturing, automotive, aerospace, electronics, and other industries depend heavily on CNC (Computer Numerical Control) manufactured parts. CNC machines, which are automated instruments that execute pre-programmed instructions to cut, shape, and finish the desired parts, are used to manufacture these components. These are some of the main purposes of components made with CNC machines:

Precision Manufacturing: production of complicated and sophisticated components is made possible by the high levels of accuracy and precision offered by CNC machines. These parts frequently have to adhere to strict dimensional specifications because of their tight tolerances. The parts are created with great accuracy thanks to CNC machining, ensuring their consistency in quality and compatibility.

Customization and prototyping: CNC machining allows for a degree of flexibility when making prototypes and custom parts. The capacity to programme the machines allows for the creation of distinctive components that are suited to particular needs. This skill is useful in fields where prototyping and customization are necessary since it enables quick iteration and the creation of new goods.

Mass Production: The mass production of components also employs CNC machining. The machine can produce huge numbers of parts with high efficiency if it has been configured to perform the same processes properly and consistently. Because of this, CNC machining is appropriate for manufacturing sectors that need high-volume production runs.

Versatility in Material Compatibility: CNC machines can deal with a variety of materials, including plastics, composites, wood, and metals (such as aluminium, steel, and titanium). Due to its adaptability, CNC machined components can be employed in a variety of settings and sectors. Various materials might need particular tools and machining processes, but CNC machines can handle them rather easily.

Complex Geometries: CNC machining makes it feasible to produce components with intricate shapes and geometries that are difficult or impossible to realise using conventional machining techniques. The machines' ability to carry out complex tasks like drilling, milling, turning, threading, and other operations enables the development of elaborate shapes and features.

High Quality and Consistency: Precision CNC machining assures high-quality components. CNC machines are automated, which removes human error and lowers production variability to produce reliable and uniform parts. This is crucial in sectors where component interchangeability and quality assurance are essential.

Cost-Effectiveness: CNC machining can be cost-effective in the long run, especially for high-volume production, despite having greater initial setup costs than alternative manufacturing techniques. Once the machine is configured and programmed, it can work independently, which lowers labour costs and boosts production.

Top CNC Machined Components suppliers in India

Some of the suppliers in India are:

-

MIFA Systems PVT. LTD.

-

Success Technologies

-

Victor Enterprise

-

Punit Industries

-

Shanghai Ehan-Am Co., LTD.

-

JNE Co., LTD

-

R R Engineering

-

A.R. International

-

Zenith Industries

-

Daksh Enterprises

-

J.K. Machines

-

Vardhaman Industries

-

Ajanta Engineers

-

D.K. Brothers

FAQs: CNC Machined Components

Q. What are machined components?

Ans. Machined components create parts or objects by using the machining process. The machining process uses a variety of cutting tools and equipment to shape and mould raw materials into the desired finished product. In the context of manufacturing, a variety of materials, including metals, polymers, and composites, can be used to create machined components.

Automotive, aerospace, electronics, machinery, and many other fields and applications frequently require machined components. Depending on the needs of the finished product, they might have simple or sophisticated designs. High precision and accuracy are made possible through machining, allowing for the creation of complex shapes, close tolerances, and flawless surface finishes.

Gears, shafts, valves, pistons, bearings, brackets, and connections are a few examples of machined parts. These parts are frequently assembled into bigger machinery or systems, where their exact measurements and functional attributes are essential to their proper performance.

Q. What parts are CNC Machined?

Ans. Computer Numerical Control is a flexible manufacturing technique used to make precise and complex pieces out of a variety of materials. CNC machining is possible for a wide range of components, including but not restricted to:

Prototypes: Before going into mass production, prototypes are often made using CNC machining for testing and validation.

Components for industrial machinery: CNC machining is used to make gears, shafts, housings, brackets, and structural parts for a variety of industrial machinery.

Automotive parts: CNC machining is used to create parts for the brake system, the suspension, the engine, and the gearbox.

Aerospace parts: The production of crucial parts including airplane engine parts, turbine blades, landing gear components, and structural components uses CNC machining extensively.

Medical devices: CNC machining is used in the production of medical equipment, such as orthopaedic parts, surgical tools, implants, and prostheses.

Electronics: CNC machining is used to create circuit boards, connectors, heat sinks, enclosures, and other precise parts for electronic equipment.

Tooling: Moulds, dies, and other tooling components needed for various manufacturing processes are made using CNC machining.

Jewellery: Using CNC machining, sophisticated and precise jewellery items made of materials like metals and gemstones can be produced.

Custom components: CNC machining is frequently used to create parts that are specifically developed for applications where high precision and complex geometries are necessary.

Q. Which motor is used in CNC?

Ans. Depending on the exact application and requirements, different types of motors can be used with CNC equipment. In CNC machines, the following motor types are most frequently used:

Stepper motors: Due to their ability to give precise movement control, stepper motors are frequently utilised in CNC machines. They rotate incrementally or in small amounts, enabling precise alignment. Applications that demand precise positioning, such 3D printers, laser cutters, and small to medium-sized CNC mills and routers, frequently use stepper motors.

Servo motors: These are a further common option for CNC machines, particularly for larger and more intricate systems. High torque, high-speed operation, and superb control are all features of these motors. The position, speed, and acceleration of servo motors are accurately controlled via a feedback system (such as encoders). They are frequently utilised in industrial-grade CNC systems, CNC lathes, and CNC milling machines.

Brushless DC motors: CNC machines are used due to their dependability and efficiency. They keep a small size while having excellent torque and speed capabilities. Since BLDC motors don't have brushes, they require less maintenance and have a longer useful life. They are utilised in CNC spindles for applications requiring high-speed milling and machining.

Q. How can I buy CNC machined components online?

Ans. These steps can be used to purchase CNC-machined components online:

Find out what you need: Decide what CNC-machined components you require, and take account of their dimensions, construction, number, and any other requirements.

Research suppliers: Find trustworthy online manufacturers or suppliers who specialise in CNC machining by doing some research on potential sources.

Evaluate suppliers: Review the websites and online profiles of possible suppliers to gauge their qualifications, experience, and client feedback. Take into account elements such as their experience, certifications, quality control procedures, and client happiness.

Request quotes: By getting in touch with the suppliers who made the shortlist and giving them the details of your component, request quotations. Asking about any minimum order quantity is also beneficial.

Comparing quotes: Consider the cost, quality, lead times, and other aspects that are crucial to your particular needs when comparing bids from various vendors.

Place an order: Decide on the order's specifics, such as the quantity, payment conditions, and delivery timetable, after selecting a provider.

Manufacturers & Suppliers of Cnc Machined Components

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 23 Years |

Zenith Industries Jamnagar, India | 17 Years |

Shree Laxmi Brass Industries Jamnagar, India | 17 Years |

Maruti International Vadodara, India | 15 Years |

Egp Sales Corporation Faridabad, India | 15 Years |

Victor Enterprise Mumbai, India | 13 Years |

Ipan Machineries (India) Pvt. Ltd. Ahmedabad, India | 13 Years |

Tools Unlimited Mumbai, India | 12 Years |

Success Technologies Ahmedabad, India | 11 Years |

Gurukrupa Bellows Pvt Ltd Pune, India | 10 Years |

Popular Products