Consumables Ceramic Brush Roller For Pcb Scrubbing/grinding

Price Trend: 500.00 - 1000.00 USD

Get Latest Price

Minimum Order Quantity :

2

In Stock

Product Specifications

| Surface Treatment | abrasive |

| Type | consumables |

| Material | ceramic roller |

| Function | remove copper particles, remove plugging resin, deburring the plugging holes |

| Application | PCB manufacturing |

| FOB Port | Guangzhou or shenzhen |

| Payment Terms | Cash on Delivery (COD), Others, Cash in Advance (CID) |

| Supply Ability | 5000Pcs Per Month |

| Delivery Time | 6 Week |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | Packed in carton boxes with good protection |

| Main Export Market(s) | South America, Western Europe, Asia, North America |

| Main Domestic Market | All India |

| Certifications | SGC, ISO |

Product Overview

Key Features

Place of Origin:

China

Brand Name: Ontop

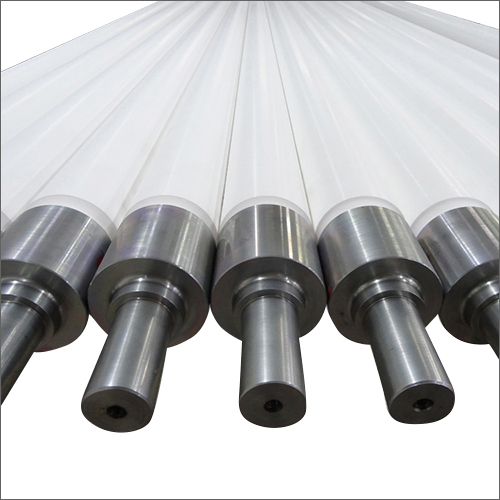

Size:

150 x 610 x 76.2mm (could be customized)

Specifications

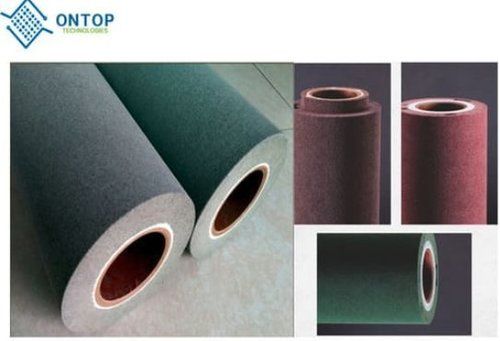

Fine Super Pellet (FSP-WM) is precision polishers for PCB (Printed Circuit Boards).

Fine Super Pellet (FSP-WM) is precision polishers for PCB (Printed Circuit Boards). This can be solved any problems on the process of producing PCB.

Features

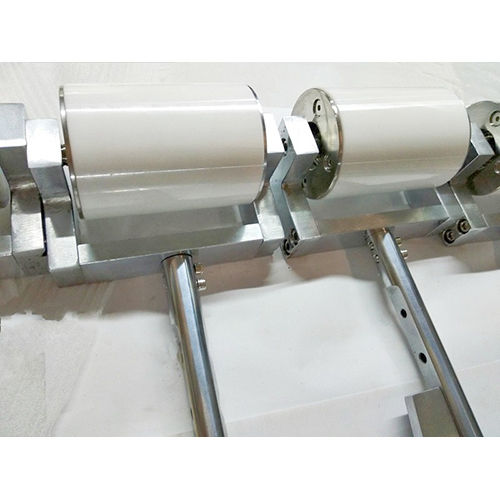

1. A roll drum type of Fine Super Pellet consists of a core,a backing,and abrasives. The backing is detachable from the abrasives.

2. Since the magic type cores pipe is reusable,the abrasives are the only wastes to be rejected and replaced with new ones after they are worn out. This contributes to minimize the problem of industrial wastes and environmental issues the users are concerned(ISO-14001).

3.The moderately flexible structure enables the product to fit well,to prevent the thin PCB from stretching,and to smooth the surface extremely well.

4.The product shows the constant sanding performance because the abrasives in each pellet are effectively derived from the pellet and prevents clogging.

5.Compared to buffs,the product can minimize clogging of the holes on the board by eliminated tips and prevent inferior printing.

6.Compared to buffs,the product improves the sanding ability and minimizes uneven surfaces around the holes caused by polishing.

Usage

1.To remove the plugging ink,paste,and the film.

2.To smooth the surface of build-up,IVH,and pre-preg.

3.To smooth the surface of additive-processed PCB.

4.To deburr the hole and to remove foreign matter after plated.

5.To polish the surface of SUS press plate.

Precision Polishers for PCB are developed, seeking the goal of low cost high quality, considering the problems of environment and industrial wastes in sanding PCB,or print-circuit board.

Works effectively on smoothing the surface such as removing the plugging paste ink on the surface of PCB and polishing the surface of build-up board and the pre-preg.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

100

Establishment

2010

Working Days

Monday To Saturday

Certification

ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Guangzhou, Guangdong

Sales Director

Mr. Ditto Yuan

Address

Room 1401, Tianyu Building No. 3 Of Tie Zhong Road, Shilou Township, Panyu District, Guangzhou, Guangdong, 511447, China

Report incorrect details