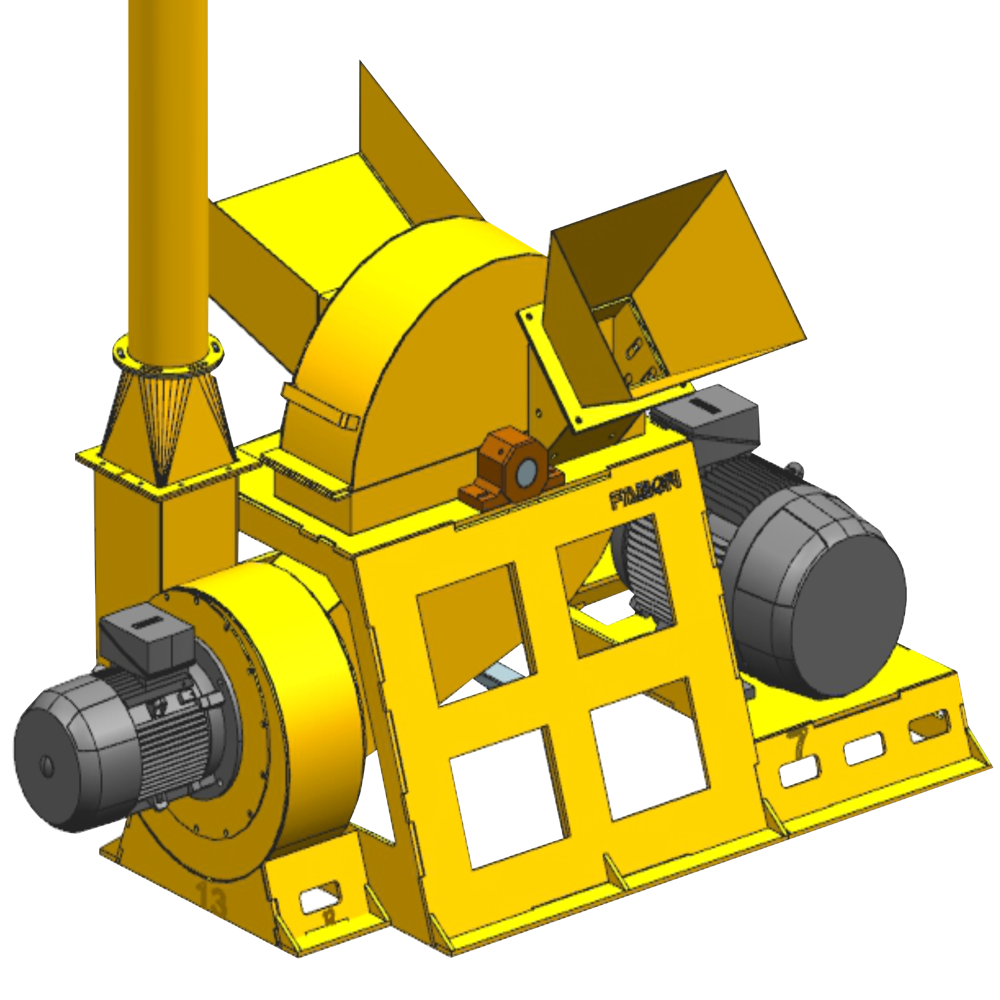

Cattle Feed Pellet Machine 75-100 Kg Hour - Color: Yellow

Price: 99750.00 INR / Unit

(95000.00 INR + 5% GST)

Get Latest Price

MRP:

99750.00 INR / Unit

Weight :

150.00 Kilogram

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Yellow |

| Type | Other |

| Material | Steel |

| Feature | Durable |

| Feeding System | Auto |

| Size | As per requirement |

| Technology | Automatic |

| Weight | 300 Kilograms (kg) |

| Supply Ability | 10 Per Week |

| Delivery Time | 2 Week |

| Sample Available | No |

| Main Export Market(s) | Africa, Asia, Australia |

| Certifications | Cattle Feed Pellet Machine (75 100 kg/hour)A compact, industrial-grade pelletizer for dairy farms, small feed mills, and pilot R&D lines. Designed for Indian conditions (dust, voltage fluctuation), with easy maintenance and low operating cost.1) Detailed Technical Specifications Rated capacity: 75 100 kg/h (formula, moisture, die size dependent) Pellet diameter options: 2 / 3 / 4 / 6 / 8 mm (interchangeable flat die) Drive power: 3 5 HP (2.2 3.7 kW), belt or gearbox drive Supply voltage: 220 240 V 1-phase or 380 415 V 3-phase, 50 Hz Control panel (standard): DOL/Star-Delta* starter, MCB, OLR, E-stop, phase protection (*Star-Delta recommended above 4 HP) Die & rollers: Hardened alloy/tool steel; crowned rollers for even load Feeder: Gravity (std) / screw feeder with VFD (opt.) Knife: Adjustable SS knife; typical pellet length 8 20 mm Discharge: Bottom spout; provision for tray/counter-flow cooler Noise level: 85 dB(A) at 1 m (with guards closed) Dust control: Top hood stub for connection to LEV (optional) Finish: Industrial enamel/PU; SS304 contact parts on request Approx. size: 900 1100 (L) 600 800 (W) 900 1200 (H) mm Approx. weight: 160 240 kg (configuration dependent)Typical output by die (indicative): 2 3 mm closer to 75 kg/h; 4 6 mm ~90 100 kg/h (with correct grind & moisture 12 16%).________________________________________2) Electrical & Power Details (India, 50 Hz) Motor FLA (approx.)o 3 HP @ 415 V 3- : ~4.6 A | @ 230 V 1- : ~14.3 Ao 4 HP @ 415 V 3- : ~6.1 A | @ 230 V 1- : ~19.1 Ao 5 HP @ 415 V 3- : ~7.6 A | @ 230 V 1- : ~23.8 A(Assuming pf 0.8, 0.85; starting current can be 3 6 FLA.) Suggested protection (typical):o 3 HP: 16 A 3-pole MCB (C-curve) + OLR set to FLAo 4 HP: 20 A 3-pole MCB (C-curve) + OLRo 5 HP: 25 A 3-pole MCB (C-curve) + OLR (prefer Star-Delta or soft-starter) Recommended cable (Cu flexible, short runs 20 m):o 3- : 2.5 mm (min); 4 mm if long run/voltage drop risko 1- : 4 mm (min); 6 mm for long run Earthing: 1 system earth; separate PE to frame________________________________________3) Upstream / Downstream Equipment (Recommended) Pre-processing: Hammer mill (1 3 mm screen), ribbon/paddle mixer, micro-dosing Conditioning (optional): Mini steam set or warm-water/molasses dosing (0.5 3%) Post-processing: Tray/ambient cooler, vibrating screen (fines recycle), bagging & stitching________________________________________4) Process Flow (Small Line)Raw material Grinding Mixing + micro-ingredients (Optional) Conditioning Pelletizer (this machine) Cooling Screening Bagging (25/50 kg)________________________________________5) Performance Benchmarks (Good Practice) Moisture into die: 12 16% Fineness: 60 80% passing 1 2 mm PDI (durability): 90 95% with proper conditioning/binder Bulk density: 550 700 kg/m Specific energy: 20 35 kWh/ton (small-scale)________________________________________6) Scope of SupplyStandard: Pellet mill on base, motor & guards, one die (chosen size), roller set, adjustable knife, control panel (DOL/SD), toolkit & manual.Options: Extra die/roller sets, screw feeder with VFD, mini-conditioner, fines cyclone, tray/counter-flow cooler, dust hood & ducting, bagging scale/sealer, SS304 contact parts.________________________________________7) Installation & Foundation Footprint: Keep ~1.5 m 1.5 m clear working zone Foundation: Level RCC floor (M20), anchor bolts recommended Alignment: True pulley alignment & belt tension; free discharge to cooler/bin LEV connection: If indoor, connect hood to 1 2 HP blower + cyclone/filter________________________________________8) Operation & Maintenance (Quick Schedule) Daily/Shift: Check belt tension, die-roller gap (typ. 0.1 0.3 mm), unusual noise/heat Every 100 150 hours: Grease bearings; inspect knife & rollers Weekly: Check MCB/OLR settings, terminal tightness, guards Wear parts to stock: 1 die (spare), 1 roller set, knife, V-belts, bearings, overload relay________________________________________9) Safety & Compliance Full belt/shaft guarding, mushroom E-stop, overload/phase protection Proper earthing & MCB/OLR per IS/IEC practice Dust kept low with LEV; PPE: ear muffs, dust masks, gloves Electricals: IEC/IS 60204-1 good practice; wiring ferruled & numbered________________________________________10) Acceptance & Guarantees Pre-dispatch inspection (PDI): No-load run, vibration, current, safety interlocks Site acceptance test (SAT): Capacity on buyer s formula/die, amperage, pellet length, visual fines Warranty: 12 months against manufacturing defects (consumables excluded)________________________________________11) Typical Formulations (Illustrative, consult nutritionist) Dairy 6 8 mm: Cereal (maize/wheat), oil cakes (DOC), rice polish/bran, mineral mix, salt, toxin binder Calf starter 3 4 mm: Finer grind, higher protein, careful conditioning________________________________________12) What Makes This Model Stand Out Right-sized for 0.75 1.0 TPD in a single shift Low skill bar: Quick die change, simple panel, easy cleaning Scalable: Same upstream kit supports upgrade to 200 500 kg/h later________________________________________13) Packing & Dispatch Packing: Stretch-wrap + wooden skid/crate; rust inhibitor on machined parts Docs: Manual, wiring diagram, test report, warranty card, spares list________________________________________14) FAQs (Extra)Q: Can I run without steam?Yes. Steam/warm-water/molasses improves PDI and reduces fines but isn t mandatory at this capacity.Q: Which die should I keep in stock?Keep one spare in your primary pellet size (e.g., 6 or 8 mm for dairy); add 3 4 mm if you also do calf feed.Q: Power backup?A 10 15 kVA genset typically covers 5 HP pelletizer plus lights/small auxiliaries.________________________________________15) Quick ROI Glimpse (Indicative) Shift output: ~0.8 ton/day (8 h @ ~100 kg/h) Conversion margin: 2.5 4.5/kg (local market dependent) Payback: ~6 12 months for micro units (validate with your inputs) |

| Brand Name | FABON |

| GSTIN | 5% |

| Pkg Box Height | 160.00 cm |

| Currency | INR |

| Product Unit | 1 Unit/Units |

| Unit Type | Unit/Units |

| Price Type | fixed |

| Weight | 150.00 Kilogram |

| Packsize | 1 |

| Color | Yellow |

| Price | 95000.00 INR (Approx.) |

| Stock Quantity | 15 |

| Pkg Box Breadth | 30.00 cm |

| Shipping Type | actual |

| Returnable | No |

| Mop | 1 |

| MRP | 99750.00 INR |

| Pkg Box Length | 100.00 cm |

| Moq | 1 |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, FABON ENGINEERING PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Poultry Equipment in bulk from FABON ENGINEERING PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

27

Establishment

2006

Working Days

Monday To Sunday

GST NO

27AADCF3398N1Z0

Payment Mode

Online Payments (NEFT/RTGS/IMPS)

Certification

ISO9001-2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AADCF3398N1Z0

Nashik, Maharashtra

Manufacture

Mr Satish Ghoderao

Members since

4 Years

Address

Sr. No. 153, Ambad-Gavalana Road, Behind D Mart, NH03, Pathardi, Nashik, Maharashtra, 422010, India

cattle feed machine in Nashik

Report incorrect details