- Tradeindia

- Food Processing Machinery

- Feeding Machine

Feeding Machine

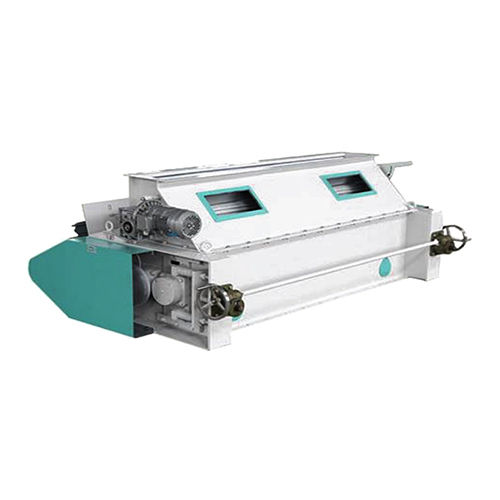

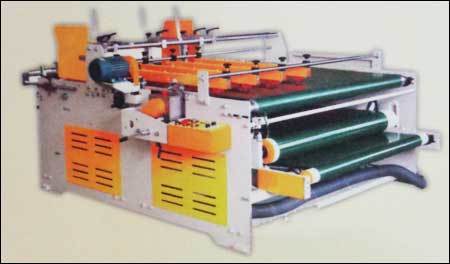

(485 products)Dual Feeding System - Attributes: Easy To Operate

Price: 550000 INR/Unit

MOQ1 Unit/Units

ColorWhite and Green

UsageIndustrial

ConditionNew

SizeDifferent Size

Product TypeDual Feeding System

AttributesEasy To Operate, Durable, Strong

Knovocon Private Limited

Howrah

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium3 Years

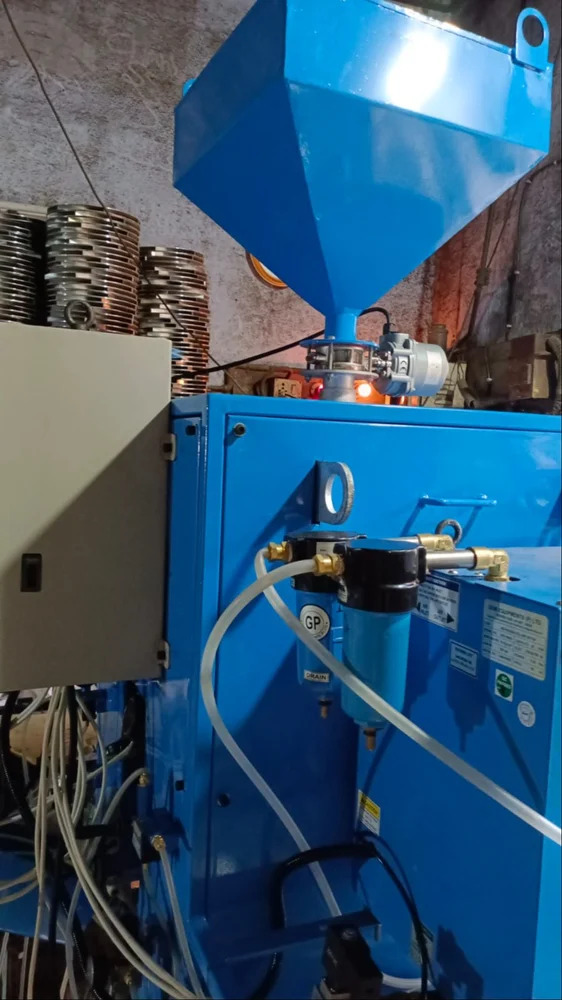

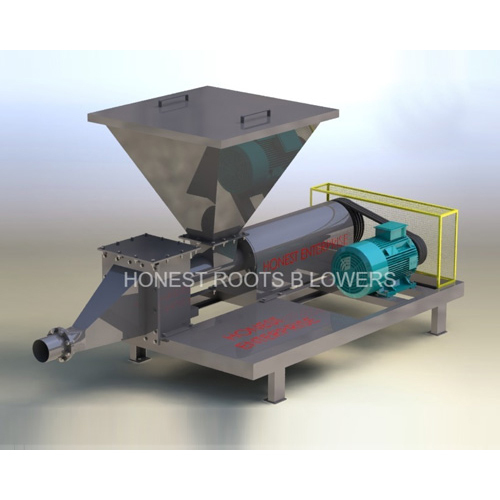

Steel Feed Making Machine

Price: 125000 INR/Set

MOQ1 , Set/Sets

TypeFeeder

MaterialSteel

Weight800 Kilograms (kg)

Rising Industries

Kolkata

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium14 Years

View More

Cattle Feed Grinding Machine, Material: Mild Steel

Get Best Deal

Fish Feed Machine, Dimensions (LxWxH): 1000*600*500

Get Best Deal

Stainless Steel Cattle Feed Machine

Get Best Deal

Seed Dryer Machine - Color: White

Price : 32500.00 INR

COW FEED MACHINE

Price: 45000 INR/Piece

MOQ1 Piece/Pieces

Speed Modeother, Single Speed

Machine TypeCattle Feed Processing

Frequency50 Hz

Operating TemperatureAmbient

ColorOther, Green & Yellow

Function TypeMixing Other, Mixing and Grinding

Zigma Machinery & Equipment Solutions

Coimbatore

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Dough Kneading Cum Feeding Machine

MaterialSteel

DimensionsVariable

PowerElectric

CapacityCustomizable

WeightHeavy-Duty

Voltage220V

Ambica Engineering Equipment Private Limited

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

Automatic Chocolate Feeding System - Color: Silver

Price: 500000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

MaterialMetal

FeatureHighly Efficient

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Industrial Hydraulic Auto Feeding Cutting Machines Body Material: Stainless Steel

Price: 750000 INR/Unit

MOQ1 Unit/Units

Product TypeHydraulic Auto Feeding Cutting Machines

Body MaterialStainless Steel

MaterialSteel

TypeHydraulic Cutting Machine

ForceHydraulic Meganewton (MN)

AutomaticYes

Santec Exim Private Ltd

Gurugram

Trusted Seller

Trusted Seller Super Seller

Super Seller23 Years

Feeding Conveyor - Mild Steel, Customized Length, 200 Kg Load Capacity, 180 m/m Speed | Durable Bucket Conveyor, Colour Coated, Industrial Use, Warranty Included

Price: 98,000 INR/Unit

MOQ1 Unit/Units

Usageindustrial

MaterialMild steel

Sizediff sizes available

TypeBucket Conveyor

Colorcolour coated

Lengthcoutomized Foot (ft)

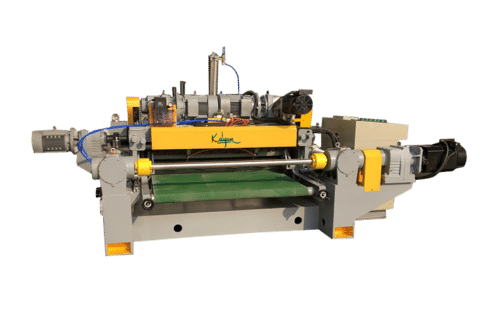

Job Feeder Special Purpose Machine

Price: 100 INR/Number

MOQ1 Number

ColorYellow and White

Product TypeJob Feeder Special Purpose Machine

MaterialSteel

CapacityHigh

ComputerizedYes

Automatic GradeAutomatic

Bale Feeding System - Color: Silver

Price: 2000000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

UsageIndustrial

ConditionNew

SizeStandard

Product TypeBale Feeding System

Power SourceElectric

Rollcon Technofab India Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller14 Years

Semi-Automatic Industrial Dri Feeding System

MOQ10 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Drive TypeElectric

Midas Autosoft Engineers Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

KI-C18 Feed Crumble Machine - Semi-Automatic, Electric Powered | Durable Painted Finish, Laser Technology Precision, Warranty Included

Price: 185000 INR/Kilograms

MOQ1 Kilograms/Kilograms

Colorany

TechnologyLaser

Power SourceElectricity

Operating TypeSemi Automatic

Product Typecrumbler machine

Surface TreatmentPainted

View More

Premium Quality Cattle Feed Making Machine With High Production, 500 Kg Per Hr Terms & Conditions

Price Trend : 50000.00 - 100000.00 INR

Tmr Feed Mixer Machine With 1 Year Warranty Installation Type: Free Stand

Price Trend : 290000.00 - 485000.00 INR

Power Efficient Cattle Feed Mixer Machine

Price : 140000 INR

Cattle Feed Machine - 500 Kg/hr Capacity, Galvanized Steel, Eco Friendly, High Efficiency, Blue

Price Trend : 50000.00 - 100000.00 INR

Semi Automatic Cattle Feed Machine - Power: 10 Hp Horsepower (Hp)

Price : 130000 INR

Poultry Automatic Pan Feeding System - Feature: Complete Turnkey

Price: 5000.0 INR/Piece

MOQ200 Piece/Pieces

TypeFeeder

MaterialSteel

Featurecomplete turnkey

Feeding Systemautomatic

SizeStandard

TechnologyAutomatic

Quality Systems And Equipments Private Limited

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

FAQs Related to Feeding Machine

Who are the top feeding machine manufacturers in India?

- Santec Exim Private Ltd

- Associated Industrial Corporation

- Rising Industries

- Zigma Machinery & Equipment Solutions

- 3teck Engineering

- Rollcon Technofab India Pvt. Ltd.

- Kalyan Industries

- Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd.

- Quality Systems And Equipments Private Limited

- Ambica Engineering Equipment Private Limited

Which cities have the largest number of feeding machine suppliers?

- Delhi

- Pune

- Mumbai

- Kolkata

- Bengaluru

- Chennai

- Hyderabad

- Coimbatore

- Ahmedabad

- Rajkot

- Noida

- Indore

- Vadodara

- Faridabad

- Surat

- Anand

- Bareilly

- Ambala

- Thane

- Nagpur

What is the price range for feeding machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| TRIMURTI ENGINEERS | INR | Hydraulic Feeding Machine | 350000 |

| VIJAY MARUTI PRINT PACK MACHINERIES | INR | Board Feeder Chain Feeding Machines | 500000 |

| UNIVERSAL WELD INDUSTRIES | INR | Co2 Mag Wire Feeding Machine | 7500 |

| GARTECH EQUIPMENTS PVT. LTD. | INR | High Performance Automatic Universal Feeding System For Industrial | 100000 |

| Ramatech Machinery | INR | Feeder Machine For Inkjet Printer | 125000 |

| ZIGMA MACHINERY & EQUIPMENT SOLUTIONS | INR | COW FEED MACHINE | 45000 |

How many trusted sellers are available for feeding machine?

- Knovocon Private Limited

- RISING INDUSTRIES

- ZIGMA MACHINERY & EQUIPMENT SOLUTIONS

- AMBICA ENGINEERING EQUIPMENT PRIVATE LIMITED

- 3TECK ENGINEERING

- SANTEC EXIM PRIVATE LTD

- Icon Conveyors

- VARDHAMAN ENGINEERING

- ROLLCON TECHNOFAB INDIA PVT. LTD.

- MIDAS AUTOSOFT ENGINEERS PVT. LTD.

- Kalsi Industries

- QUALITY SYSTEMS AND EQUIPMENTS PRIVATE LIMITED

- Grain & Pulses Engineers Pvt. Ltd.

- Milvin Agro Machinery

- CODEZI ENGINEERING SOLUTIONS PVT. LTD.

- Farmiaze Engitech Private Limited

- KALYAN INDUSTRIES

- FOSHAN SHUNDE KINGTOOL ALUMINUM PROCESSING MACHINERY CO., LTD.

- TRIO RENEWABLE ENGINEERING PRIVATE LIMITED

- Saw Equipments And Automations

- RR Systems

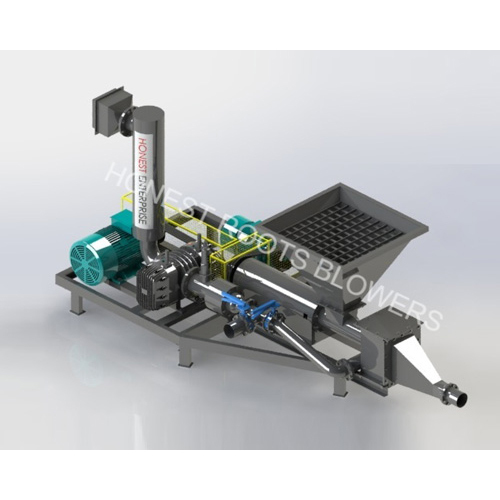

- HONEST ENTERPRISE

What is the minimum order quantity for feeding machine?

Do listed companies have registration & certifications?

- Knovocon Private Limited

- RISING INDUSTRIES

- SANTEC EXIM PRIVATE LTD

- VARDHAMAN ENGINEERING

- ROLLCON TECHNOFAB INDIA PVT. LTD.

- ASSOCIATED INDUSTRIAL CORPORATION

- WELCO GARMENT MACHINERY PVT. LTD.

- RR Systems

What is the get latest price feature?

What types of payment methods are accepted by the feeding machine suppliers?

Pnuematic Flux Feeding System - Color: Blue

Price: 250000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

MediaAir

StructurePneumatic

UsageIndustrial

Size200-400 mm Max Width

MaterialMild Steel

Feeding Machine - Capacity: 4 Ton/Day

Price: 75000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialOther, Stainless Steel

Capacity4 Ton/day

AutomaticYes

Control SystemPLC Control

Voltage220 Volt (v)

Grain & Pulses Engineers Pvt. Ltd.

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

60Kg Animal Feed Machine - Color: Yellow

Price: 39999.0 INR/Unit

MOQ1 Piece/Pieces

Machine TypeSEMI AUTOMATIC

Control SystemSemi-Automatic

Country Of OriginINDIA

ColorYELLOW, GREEN

Voltage220 Volt (v)

Product TypeAgricultural Machine

Milvin Agro Machinery

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

View More

10HP 8mm Cattle Feed Machine

Price : 95000 INR

10 HP Animal Feed Machine

Price : 95000 INR

60kg Poultry Feed Machine

Price : 40000 INR

Animal Cattle Feed Making Machine

Price : 40000 INR

Cattle Feed Making Machine

Price : 50000 INR

Three Phase Poultry Feed Machine 5HP

Price : 50000 INR

Auto Board Feeding Unit - Color: White

Price: 1000000 INR/Unit

MOQ5 Unit/Units

GradeSemi-Automatic

ColorWhite

TypeOther, Auto Board Feeding Unit

MaterialStainless Steel

ComputerizedNo

Control SystemFrequency Speed Control

Material Feeding System - Feature: High Performance

Price: 4500000.0 INR/Unit

MOQ1 Unit/Units

Product TypeMaterial Feeding System

General UseIndustrial

MaterialCarbon Steel

ComputerizedNo

AutomaticYes

Touch ScreenNo

Codezi Engineering Solutions Pvt. Ltd.

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Potry Feed Making Machine - Automatic Grade: Semi-Automatic

Price: 130000.0 INR/Unit

MOQ1 Piece/Pieces

Usage & ApplicationsCommercial

MaterialMild Steel

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Drive TypeElectric

Voltage240 Volt (v)

Farmiaze Engitech Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Automatic Through Feed Edge Banding Machine - Mild Steel, 10-50 mm Working Height, 0.4-3 mm Edge Thickness | Automatic, Digital Indicators, 12-18 m/min Feeding Speed

MOQ1 Unit/Units

TypeAutomatic Through Feed Machine

MaterialMild steel

ComputerizedYes

Automatic GradeAutomatic

ColorWhite,Blue

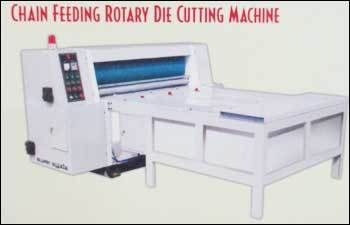

Chain Feeding Rotary Die Cutting Machine - Electric-Pneumatic-Hydraulic Control System | High Production Efficiency, Fault-Free Assurance

ModelVariable

Power3-Phase

Dimensions1500x1000x1200 mm

MaterialSteel

Cutting Speed100-200 ppm

UsageDie-cutting various materials such as paperboard, cardstock, and more.

View More

Partition Slotting Machine (Auto Feeding)

Get Best Deal

Chain Feeding Rotary Die Cutting Machine - Automatic Grade: Automatic

Price : 124500 INR

Auto Cloth Feeding Device

ModelYb-180Wb

AlignmentY

Cloth StirY

Length ConcenterElectric

Max Width1800 Mm

Inspecting Speed0~24 M/Min

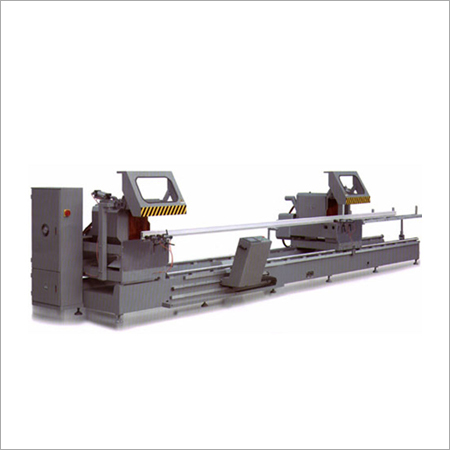

Aluminum Cutting Machine (Auto-Feeding)

Cutting length10-830mm

Cutting width200*120mm

Cutting height230*100mm

Main motor power2.2KW

Main motor rotation speed2840r/min

Saw blade dimensionD450*d30*120T

Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd.

Foshan

Trusted Seller

Trusted Seller14 Years

View More

High Precision Auto Feeding Single Head Saw - 500mm Blade, 5000x1250x1350mm Dimensions, Gray Color | Automatic Feeding, High Efficiency, 1-Year Warranty

Price : 11500 USD ($)

High Performance End Milling Machine By Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd.

Price : 4000.0 USD ($)

3-Roller Bending Machine - 4mm Iron/6mm Aluminum Thickness Capacity, 3000mm Width, 1500Kg Weight, 5Kw Motor Power

Get Best Deal

CNC Bending Machine KT-343C

Get Best Deal

Automatic Feeding Unit - Capacity: 2-2.5 T/Hr

Price: 790000.0 INR/Unit

MOQ1 Unit/Units

Power SourceElectric

Automation GradeAutomatic

FeaturesHigh Quality

Operating TemperatureAs per industry standard Celsius (oC)

Frequency50 Hertz (HZ)

General UseIndustrial

Trio Renewable Engineering Private Limited

Jaipur

Trusted Seller

Trusted Seller1 Years

Feeding Unit With Saturation Coil - Operating Type: Semi Automatic

Price: 800000 INR/Set

MOQ1 Set/Sets

TechnologyMagnetism

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentGalvanized

WarrantyYes

Feeding Systems - Feature: High Efficiency

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel Alloy

AutomaticYes

Control SystemFrequency Speed Control

Surface TreatmentPolishing

Voltage220 Volt (v)

Dual Feeding System Machine - Color: White And Yellow

Price: 480000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite And Yellow

Product TypeDual feeding system machine

MaterialSteel

UsageIndustrial

Smart Measuring Feeding System

Automation GradeYes

Power SourceElectrical

FeaturesEasy to Install, Easy to Operate, Energy Efficient, Heavy-Duty

Product TypeSmart Measuring Feeding System

General Usefor Industrial

MaterialStainless Steel

Manual Bag Feeding Machine - Automatic Grade: Semi Automatic

Price: 250000 INR/Unit

MOQ1 Unit/Units

General UseIndustry

TypeBag Feeding Machine

Capacity36 T/hr

Automatic GradeSemi Automatic

Dimension (L*W*H)3000mmX1800mmX1800mm Millimeter (mm)

FeatureHigh Quality

View More

Dual Cement Feeding Machine - Automatic Grade: Semi Automatic

Price : 485000 INR

Manual Cement Bag Feeding Machine - Automatic Grade: Semi Automatic

Price : 490000 INR

Semi Automatic Cement Silo Feeding Machine - Capacity: 40 Ton

Price : 500000 INR

Industrial Cement Feeding Machine - 850 Kg Weight, 4.5 x 3 x 4.5 ft Dimensions, 30 Ton Capacity | Semi-Automatic, 220-440 Volt Compatibility

Price : 255000 INR

Metal Cement Feeding Machine - Automatic Grade: Semi Automatic

Price : 490000.0 INR

Cement Manual Bag Feeding Machine - Automatic Grade: Semi Automatic

Price : 230000.0 INR

Popular Feeding Machine

How Feeder Machines Facilitate Easy Material Movement?

Feeder Machines are the lifeline of industrial spaces including manufacturing, construction, warehousing, etc, where frequent material handling processes are carried out with precision and accuracy. This industrial-grade equipment facilitates the movement of material into the equipment, making operations smooth and swift. Feeder Machines are equipped with conveyor belts, vibratory motors, pneumatic systems, etc, allowing them to move material from one location to another. This reduces the requirement of manual feeding and enhances the overall productivity levels.

Major Applications of Feeder Machines

-

Manufacturing

Feeder Machines are most commonly used in manufacturing fasciitis to streamline material movement from one assembly line to another. They help move various parts, machine components, products, etc. The automatic movement of these items enhances the productivity levels and reduces the downtime.

-

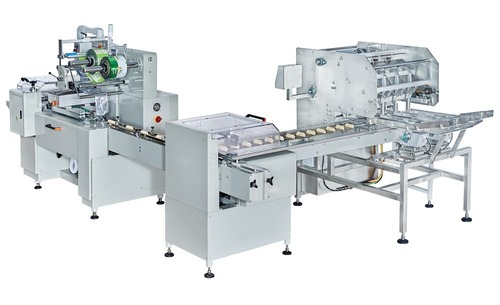

Packaging

Feeder Machines are extensively used for packaging operations to facilitate product movement into the packaging equipment including bottles, containers, cartons, caps, etc. The packaging equipment includes filling machines, capping machines, wrapping machines, etc. Feeders offer precision and accuracy.

-

Food Processing

The Food Industry employs feeder machines to facilitate the movement of various food products and ingredients between stations including fruits, veggies, grains, etc. These items are moved across stations for processes including packaging, processing, sorting, grading, etc. Feeder Machines feature a hygienic environment and contribute to improving productivity levels.

-

Pharma

Feeder Machines are used across pharmaceutical products manufacturing facilities for moving materials to the machines including ingredients, medicines, syringes, capsules, and other types of medical equipment. These machines are either used for further processing the ingredients, packaging products, etc.

-

Automotive

Feeder Machines are most commonly hired in the automotive industry to enhance the manufacturing process by streamlining the movement of components between stations or machines for further processing. These components or parts include fasteners, nuts, bolts, bearings, electric motors, engines, etc.

-

Electronics

In the electronics product manufacturing industry, feeder machines are hired to facilitate the movement of electronic components including chips, connectors, PCBs, etc. into assembly machines or between stations for further processing. These machines carry out essential tasks including pick and place, soldering, assembling components, etc.

-

Textiles

Feeder Machines are most commonly hired in the textiles industry for moving or feeding ingredients like fabrics, yarns, fibers, etc into the various machines facilitating essential processes including knitting, weaving, sewing, etc. Feeders assist in maintaining a consistent flow of materials and enhance productivity levels.

-

Printing and Labeling

For printing and labeling processes, feeder machines are hired to feed essential materials or ingredients into machines for further processing. These materials include paper, cardboard, labels, kinds of packaging material, etc, which are fed into machines for printing, labeling, and various other essential processes.

-

Recycling and Waste Management

Feeder Machines are extensively used in recycling and waste management for feeding waste materials like plastic, paper, metal, cans, glasses, organic waste, etc into recycling machines for further processing. These materials are sorted, shredded, and sent for reproducing new products.

Key Benefits of Feeder Machine

-

Increase Efficiency

Feeder Machines improve the efficiency levels of whichever industrial process they are hired for. They automate the process of feeding materials or ingredients into the equipment for further processing with consistency, without the need for manual intervention. This helps businesses as the output rate becomes higher and reduces the labor cost.

-

Enhance Accuracy

Accuracy is highly essential in industrial settings as minute errors can also lead to production failure. Feeder Machines enhance the accuracy of the industrial process by streamlining the consistent flow of materials or ingredients for higher output. Including high product quality, feeders eliminate the chance of human error with automation.

-

Reducing Downtime

Feeder Machines facilitate the consistent flow of material or ingredients into the various machines used in the processing, production, and packaging phases. This reduces the downtime and elevates the productivity levels.

-

Flexible and Adaptable

Feeder Machines are designed to facilitate the feeding process for various kinds of materials, varying in shape, size, etc. This makes them very flexible in supporting a diversified range of production processes across industries. Moreover, feeders can be reconfigured to support the new changes in the production phase. They can easily adapt the new settings and aid in enhancing the manufacturing process.

-

Labor Savings

Feeder Machines bring automation to your facility and help reduce manual work, eliminating the labor cost by a huge margin. Moreover, with the automatic feeding process, the workers can now concentrate on more crucial tasks, best for their skills.

-

Improved Safety

Automating feeding requires no manual intervention, so no worker needs to perform hard labor work. This eliminates the chances of injuries and any sort of hazardous incident that can take place because of human error. A safe working environment encourages the workers to show higher productivity levels without worrying.

-

Conservation of Resources

Feeder machines are designed to optimize the use of materials by controlling their flow and preventing wastage. This conservation of resources not only reduces material costs but also aligns with sustainability goals by minimizing waste generation and environmental impact.

-

Process Optimization

By controlling the flow of materials into production processes, feeder machines enable better process control and optimization. They help maintain consistent material inputs, which is critical for achieving desired process parameters and product quality.

-

Integration with Automation Systems

Feeder machines can be seamlessly integrated into broader automation systems, enabling interconnected workflows and real-time data exchange. This integration facilitates centralized control, monitoring, and optimization of production operations.

-

Competitive Advantage

Implementing feeder machines can provide a competitive advantage by improving productivity, quality, and responsiveness to customer demands. Companies that leverage feeder automation effectively can differentiate themselves in the market and enhance their overall competitiveness.

How to Choose a Feeder Machine For Yourself?

Here are the factors to consider before choosing a feeder machine for yourself:

-

Define Your Requirements

Start by clearly defining your requirements and objectives. Consider factors such as the type of material you need to feed, its size and shape, required feeding rate, production volume, space constraints, and any specific features or functionalities you may need.

-

Research Available Options

Conduct thorough research on available feeder machines that meet your requirements. Explore different types of feeders, such as vibratory feeders, screw feeders, belt feeders, and pneumatic feeders, to understand their capabilities, advantages, and limitations.

-

Evaluate Feeder Performance

Assess the performance characteristics of each feeder option, including feeding accuracy, speed, capacity, reliability, and ease of operation. Look for features that contribute to consistent material feeding, minimal downtime, and easy maintenance.

-

Consider Material Compatibility

Ensure that the feeder machine you choose is compatible with the type of material you'll be handling. Some feeders are better suited for handling fragile or abrasive materials, while others may be designed specifically for powders, granules, or bulk solids.

-

Assess Integration and Compatibility

If you're integrating the feeder machine into an existing production line or automation system, consider compatibility with your existing equipment and control systems. Look for feeder machines that offer easy integration options and support standard communication protocols.

Client Testimonials & Reviews

MohitAgarwal

APEX SHEARS PVT. LTD.

Apex Shears is a valuable member of Tradeindia and we have been using its services for a few years. We are always pleasantly surprised with the improvements made by Tradeindia every year both in terms of their product offering as well as their customer services. Since Apex Shears is a manufacturer of tailor made industrial machine knives and blades, we have found several potential and new clients using Tradeindiaa s portal. We believe that Tradeindia a s SEO services are able to drive traffic to our catalog page or our own website and this has resulted in fresh business opportunities for our company.

Bhupindersingh

LUDHIANA ENGINEERING WORKS

We Ludhiana Engineering works its our pleasure to associate with tradeindia.com. Tradeindia.com gives us good platform to explore our products and company in domestic mainly in local market. I have generated lots of business after associating with tradeindia.com. We appreciate your team service and your guidance that you give us. And looking for same in future also. All the best tradeindia.com.

SanjayRaichura

ALFA MACHINE TOOLS

We, The Alfa Machine Tools the manufacturer of Khakhara making machine and chikki making machine, We glad to inform you that after get listed in the business portal in tradeindia.com we get good response from the portal and we get good business from it, so we are thankful to the entire team of tradeindia.

RahulSoni

YASH BLOWERS PRIVATE LIMITED

Thanks to the entire team at Tradeindia for providing constant support and business inquiries. Innovative solutions & good online reach has helped my business grow. Special mention for their Sales & CRM teams for their excellent account management, delighted to engage with them & Tradeindia for long term. Highly recommended for B2B.

We are associated with tradeindia from last 7 year and this platform helped us to improve and grow our Business, Branding and Promotion. I am getting inquiry and I expect the same in future.

Bhavesh Gajjar

DEVI TECHNOCRAFT PVT. LTD.

We are happy to inform you that we are receiving very good inquiries after advertising with trade India and which is also helping us in improving our export turnover. We would be looking forward for a long term association with trade India. All the very best to trade India and its family.

We foodies group of consultant are the member of Tradeindia from last 6 years. We get regular service at our office by your personnel. The platform is good for finding target customers.

R.Chandrasekaran

R. SHUNMUGAM PILLAI & SONS

We are in to manufacturing and exporting of Roaster machines and its parts to roast any grains, seeds, nuts in continuous type of roasting. We are associated with tradeindia.com for the past five years. We are extremely pleased with the quality of customer service, and inquiries & its conversation ratio. We are very much comfort with the tradeindia.com platform & tradeindia.com made us delight in business promotions.

AkhtarKhan

A. S. ENGINEERING WORKS

We are very thankful to you and tradeindia.com for such good services, which you people are giving us. You help a lot to explore business and promotion of our company on your portal.

SumatilalSheth

JAS ENTERPRISE

Jas Enterprises is the leading manufacturers for pulverizers, hammer mills, spices mills and food processing machines like papad making machines, noodle machines, vermicelli machines, dal mill, namkeen making machines, beverage processing machines in Gujarat at Ahmedabad .We have been associated with INFOCOM NETWORK LTD, since seven years and we feel happy to say that their service have been find excellent, I am really happy with the efforts which the INFOCOM NETWORK LTD team has promoted my company and products Domestic as well as International Market. Specially I would like to thank Ms. Sushma Verma an employee of INFOCOM NETWORK LTD. for serving my account in decent way, various innovative steps to promote my business and her timely response and am I equally thankful for the efforts of INFOCOM NETWORK LTD team. We wish to continue with their improving services in years to come. We look forward for a long association with INFOCOM NETWORK LTD. All the best for Trade India team.

Feeding Machine Price List

Product Name | Expected Price |

|---|---|

| Hydraulic Feeding Machine | 350000 |

| Board Feeder Chain Feeding Machines | 500000 |

| Co2 Mag Wire Feeding Machine | 7500 |

| High Performance Automatic Universal Feeding System For Industrial | 100000 |

| High Performance Automatic Feeding System For Industrial | 100000 |

| Feeder Machine For Inkjet Printer | 125000 |

| COW FEED MACHINE | 45000 |

This Data was Last Updated on 2025-12-24

Feeding Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Santec Exim Private Ltd Gurugram, India | 23 Years |

Associated Industrial Corporation Amritsar, India | 21 Years |

Rising Industries Kolkata, India | 14 Years |

Zigma Machinery & Equipment Solutions Coimbatore, India | 14 Years |

3teck Engineering Thane, India | 14 Years |

Rollcon Technofab India Pvt. Ltd. New Delhi, India | 14 Years |

Kalyan Industries Yamunanagar, India | 14 Years |

Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd. Foshan, China | 14 Years |

Quality Systems And Equipments Private Limited Mumbai, India | 13 Years |

Ambica Engineering Equipment Private Limited Bengaluru, India | 12 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories