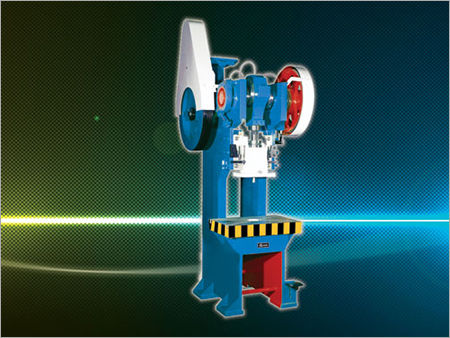

C Type Power Press - Steel Body, Inclinable Type | Precision Engineering, Energy Efficient, Robust Design, Longer Service Life

Price:

Get Latest Price

In Stock

Product Specifications

| Type | Power Press |

| Frame Material | Steel |

| Clutch Type | Pin/Rolling Key |

| Capacity Range | 3-250 Ton |

| Usage | Cutting, blanking, piercing, drawing, trimming |

| Body Color | Blue |

| Stroke Adjustment | 6-165 mm |

| Features | Robust construction, Longer life, Energy efficient, Precise engineering, Versatile usage |

Product Overview

Key Features

As

an affluent exporter and supplier, we are offering an excellent

quality assortment of C Type Power Press.

As the name suggest, this machine is designed in C shaped and used

for cutting, blanking, piercing, drawing and trimming purposes. It is

manufactured by our associated vendors using quality-tested

components and progressive techniques. Available in various technical

specifications, this C Type Power Press

is offered to clients at most competitive price.

Features:

Precision engineering

Robust construction

Longer service life

Energy efficient

Steel body fixed, Inclinable type power press | |

Fram : | The frame is of all steel construction, fabricated |

Clutch : | The clutchis of pin/rolling key-type. the clutch |

Crank Shaft : | Crank shaft is made of special alloy steel |

Flywheel : | Properly sized flywheel, is made of high grade |

Gears : | Gear are of steel cast or fabricated. Gear teeth |

Table & Ram : | Table and fam are made pf high grade heavy duty |

Lubrication : | An efficient shot luvrication system has been |

Inclining : | Inclinable type presses are provided with |

Mechanism : | Position by spanners within minutes. the press ils |

Standard Accessories

Motor pulley

Clutch key

Clutch key springs

Slide adj. spanner

Fly wheel & grar guard

Oil cups for lubrication

pointKnock-out system

inclination arrangement in

50 ton & abovem

Optional Accessories

Two hand operated clutch

Single / continuous stroke

Lubrication pump Manual

Lubrication pump automatic

Electrical

Tie - rod

Tommy bar

Extra base plate

Inclinable arrangement

from 5 to 30 TonStroke Counter

Feeder De Coiler

StraightenerOverload Safety above 30

Ton(Mechanically)Foundation Bolt

TON CAP | 3 | 5 | 5 | 10 | 10 | 10 | 15 | 20 | 20 | 30 | 30 | 50 | 60 | 75 | 85 | 100 | 150 | 200 | 250 |

CRK DIA | 38 | 51 | 51 | 60 | 60 | 60 | 70 | 76 | 76 | 83 | 83 | 95 | 101 | 115 | 115 | 127 | 152 | 158 | 165 |

STR AD | 2-19 | 6-25 | 6-38 | 6-25 | 6-51 | 6-51 | 10-51 | 13-51 | 13-76 | 13-63 | 13-89 | 13-76 | 13-80 | 13-102 | 13-102 | 13-115 | 13-127 | 13-152 | 13-165 |

SLIDE ADJ | 20 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 40 | 40 | 50 | 50 | 60 | 60 | 70 | 70 |

HOLE IN RAM | 19 | 25 | 25 | 25 | 25 | 25 | 32 | 32 | 32 | 38 | 38 | 51 | 51 | 51 | 51 | 55 | 55 | 63 | 63 |

HOLE IN BED | 51 | 63 | 75 | 76 | 76 | 76 | 89 | 89 | 89 | 102 | 100 | 127 | 127 | 178 | 178 | 191 | 203 | 216 | 216 |

LxW OF BED | 255x150 | 305x178 | 305x178 | 356x203 | 356x203 | 406x254 | 457x305 | 457x305 | 508x355 | 508x355 | 559x406 | 660x406 | 711x508 | 711x508 | 760x595 | 813x558 | 914x610 | 965x660 | 1067x711 |

DIST BED TO RAM | 152 | 152 | 175 | 180 | 205 | 205 | 205 | 230 | 254 | 266 | 305 | 290 | 320 | 330 | 350 | 381 | 410 | 432 | 485 |

STROKE / MIN | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

D.GEAR(SPM) | - | - | - | - | - | - | - | 50 | 50 | 40 | 40 | 30 | - | - | - | - | - | - | - |

S.GEAR(SPM) | 90 | 80 | 80 | 80 | 80 | 80 | 75 | 60 | 60 | 55 | 55 | 50 | 50 | 40 | 40 | 30 | 30 | 30 | 30 |

UN GEAR(SPM) | 165 | 150 | 150 | 130 | 130 | 130 | 120 | 120 | 120 | 115 | 115 | 90 | - | - | - | - | - | - | - |

H.P./RPM(UG) | 0.5/960 | 0.5/960 | 0.5/960 | 1/960 | 1/960 | 1/960 | 1.5/960 | 2/960 | 2/960 | 3/960 | 3/960 | 5/960 | - | - | - | - | - | - | - |

H.P/RPM(G). | 0.5/1440 | 0.5/1440 | 0.5/1440 | 1/1440 | 1/1440 | 1/1440 | 1.5/140 | 2/1440 | 2/1440 | 3/1440 | 3/1440 | 5/1440 | 5/1440 | 7.5/440 | 7.5/1440 | 10/1440 | 15/1440 | 20/1440 | 25/1440 |

FLOOR TO TOP OF BED | 520 | 690 | 690 | 730 | 718 | 730 | 740 | 815 | 844 | 815 | 856 | 900 | 900 | 915 | 915 | 915 | 915 | 915 | 915 |

WT KG APPROX | 200 | 300 | 350 | 450 | 475 | 525 | 700 | 900 | 1050 | 1100 | 1435 | 2350 | 2700 | 3500 | 4050 | 5000 | 6000 | 9500 | 11500 |

Company Details

Focusing on a customer-centric approach, J. R. RAO & CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machinery & Parts in bulk from J. R. RAO & CO. at Trade India quality-assured products.

Business Type

Exporter, Importer, Supplier, Trading Company

Establishment

1983

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Bengaluru, Karnataka

Proprietor

Mr. U. C. R. Prasad

Address

706, 7th Floor, Devatha Plaza 131, Residency Road, Bengaluru, Karnataka, 560025, India

c type power press in Bengaluru

Report incorrect details