Bleaching Clay - Premium Quality Absorbent Clay For Vegetable Oil Refining, Effective Impurity Removal And Color Decolorization

Price: 12000.00 INR

(12000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Material | Bentonite clay |

| Packaging | Bags |

| Particle size | Variable |

| Moisture content | Low |

| Purity | High |

| Color | Light green |

| PH | Neutral |

| Features | Oil purification, Removes impurities, Improves oil quality, High absorption, Cost-effective, Versatile application, Improves taste, Enhances appearance |

| Payment Terms | Letter of Credit (L/C) |

| Supply Ability | 1000 Tons Per Month |

| Delivery Time | 15 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | Bags |

| Main Export Market(s) | Australia, Middle East, Asia |

| Brand Name | KALINDI INTERNATIONAL |

| Product Unit | 5 Short Ton/Short Tons |

| Stock Quantity | 15 |

| Returnable | No |

| Price | 12000.00 INR (Approx.) |

| Packsize | 1 |

| Moq | 1 |

| Price Type | fixed |

| Unit Type | Short Ton/Short Tons |

| Mop | 1 |

| Currency | INR |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

| GSTIN | 0% |

Product Overview

Key Features

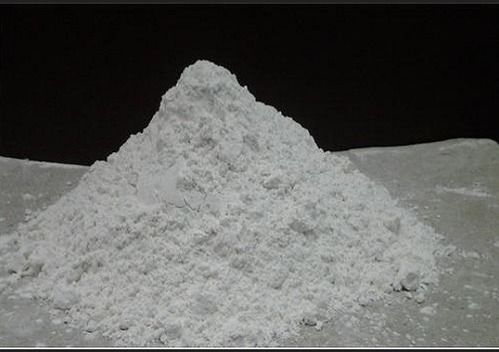

Bleaching involves the use of bleaching earths or clays. The term itself is misleading as colour removal is not the most important purpose of the bleaching process.

Vegetable oils contain contaminates that adversely affect the performance, appearance and taste of the oil. In order for it to be used in edible applications, the oil must meet high quality standards that require the removal of various impurities. It is used to decolorize purification in the field of animal and vegetable oil refining. It can take off the harmful pigments, phospholipids, cotton, acid, and so on in oil to make high-grade edible oil. And the decolorant of edible oil grade is widely applicable to all kinds of vegetable oils, animal oil and mineral oil, such as soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, palm oil, coconut oil, castor oil, camellia oil, corn germ oil, refined bran oil, sesame oil, safflower oil, and so on.

The bleaching process essentially removes some colour from the oil; reduces how much chlorophyll and carotinoids the oil contains; removes soap, gums and trace metals; and decomposes oxidation products.

Bleaching is performed prior to other processing steps such as hydrogenation, refining or deodorisation. Suppliers of the clays say that bleaching earth will account for 4-10% of overall refining costs, depending on a variety of factors including oil type, dosage, oil contaminant levels, specification and disposal cost.

What are bleaching earths?

Oils are bleached using a powdered, surfactant material. Simply put, the powder is mixed with water, and then added to the oil where they absorb unwanted impurities before they are removed from the oil again, taking the impurities with them.

Bleaching earths are generally composed of up to three types of clay minerals: bentonite, attapulgite and sepiolite. The minerals act as absorbers with capacity being dependent on mineralogical structure and properties, such as surface area, particle size distribution, porosity and surface activity.

Bentonites are a soft stone with the capacity to absorb substances dissolved in water and other liquids. The minerals have been formed over time due to the natural adaptation of volcanic ash.

Dry bleaching vs wet bleaching

The two different methods utilising bleaching clays in the refining process are dry bleaching and wet bleaching. According to Alfa Laval, dry bleaching is the traditional method used for bleaching oils and fats. It is most common in Europe and Asia, but is used worldwide.

The process first involves heating the oil, then mixing it with bleaching earths or activated carbon (or a mix of both). This process takes place under vacuum "which prevents oxidation" and with a sparging steam (the direct injection of steam in order to heat the oil with very high energy levels).

Because the bleaching takes place under vacuum of about 70 torr, the humidity of the oil is greatly reduced.

Following the bleaching process, the powder is removed using pressure leaf filters and is collected in a buffer tank, which also operates under a vacuum.

Dry bleaching requires a much lower initial investment than wet bleaching. The operating costs are also significantly less due to the use of plate heat exchangers, which require lower consumption of utilities. The process is also relatively easy and straightforward and requires only minimum space for set-up.

Company Details

Focusing on a customer-centric approach, KALINDI INTERNATIONAL has a pan-India presence and caters to a huge consumer base throughout the country. Buy Metals & Alloys in bulk from KALINDI INTERNATIONAL at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

5

Establishment

1995

Working Days

Monday To Saturday

GST NO

09AAAFK7697K1ZM

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09AAAFK7697K1ZM

Gautam Buddh Nagar, Uttar Pradesh

Partner

Mr Hari Goenka

Address

A 85, Basement, Dist. Gautam Buddh Nagar, Uttar Pradesh, 201301, India

bentonite clay in Gautam Buddh Nagar

Report incorrect details