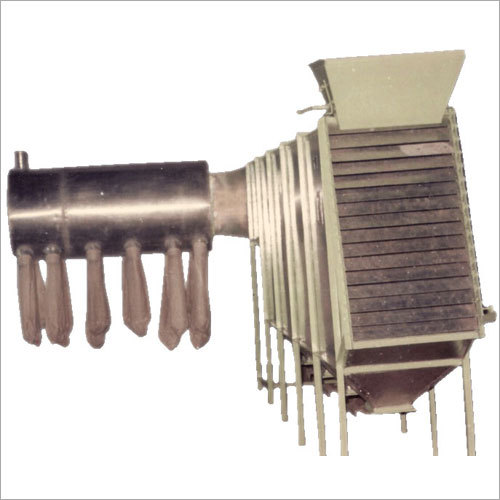

Automatic Continuous Withering Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Withering Machine |

| Dominant Color | Orange |

| Capacity | Variable |

| Power Consumption | 50% less |

| Space Required | 1/3 standard |

| Material | Steel |

| Automation | Fully Automatic |

| Usage | Continuous tea leaf withering |

| Dimensions | Variable |

| Features | Continuous process, Reduced space, Lower power, Consistent wither, Zero leaf damage, Low labor cost |

Product Overview

Key Features

WIZARD, the world's first & most advanced Automated Continuous withering system has transformed traditional withering practices.

WIZARD converts batch process of tea to continuous process by incorporating Chemical and Physical Withering in two stages.

The machines have conveyorised Leaf Feed and Leaf discharge arrangement.

Salient Features & Advantages:

- Area needed is 50% less compared to troughs

- Power requirement half of conventional method

- Low cost of withering

- Consistent wither percentages in spite of varying ambient conditions

- Leaf damage and wastage totally eliminated.

- Labour cost and involvement almost zero

Specifications:

| DESCRIPTION | CONVENTIONAL TROUGHS | a THE WIZARD' |

| Cost of withering | Standard | 50 % of standard cost |

| Space | Standard area | 1/3 of standard area |

| Building construction | Heavy and expensive | Light and much less expensive |

| Power | Standard units | 50% of standard units |

| Labour | Standard requirement | 15% of standard requirement |

| Spreading | Manual | Automatic |

| Shufi ing | Manual | Automatic |

| Spillage | Large | None |

| Leaf damage/wastage | Yes | Nil |

| Wither | Uneven | Even and consistent |

| Supervision and control | Multi station and difi cult | Single point and easy |

| Quality of tea | Inconsistent | Absolutely consistent |

| Maintenance | Constant and expensive | Periodic and less expensive |

| Feed & Discharge | Manual | Conveyorized |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1949

Working Days

Monday To Sunday

GST NO

19AAACT8460G1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 19AAACT8460G1Z4

Kolkata, West Bengal

Executive Chairman

Mr. Sajjan Bagaria

Address

11, Jassal House, 4-A, Auckland Square, Kolkata, West Bengal, 700017, India

tea processing machinery in Kolkata

Report incorrect details