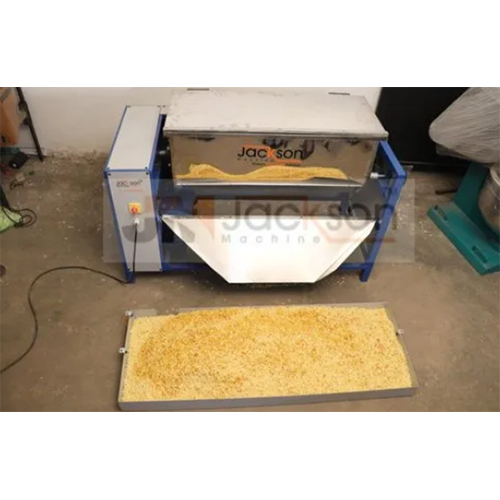

Automatic Boondi Making Machine - Polished Stainless Steel, Electric Powered With Lower Energy Consumption & High Efficiency | Compact Structure & Low Noise, 1 Year Warranty

Price Trend: 55000.00 - 450000.00 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Product Type | Automatic |

| Material | Stainless Steel |

| Type | Food Processors |

| Installation Type | Free Stand |

| Feature | Lower Energy Consumption, High Efficiency, Low Noice, Compact Structure |

| Warranty | 1 Year |

| Payment Terms | Cash on Delivery (COD), Paypal, Cheque |

| Supply Ability | 100 Per Month |

| Delivery Time | 6 Days |

| Packaging Details | Wooden Packing Cases |

Product Overview

Key Features

Machine Type:Automatic

Surface Finishing: Polished

Usage/Application: Commercial

Condition: New

Customized: Customized

Power Source: Electric

Automatic Grade: Automatic

Raw Material:Wheat Flour

Product: Boondi Making Machines

Company Details

We, being awarded the Prestigious ISO 9001 Certification, are engaged in the Manufacture and Export of Food Processing Machineries for the preceding 4 Decades and have our periphery extremely and solidly established in almost all Food Processing Industries , namely Flour Mills, Dall Mills, Spices Processing, Instant Food, Supari Processing, Pharmacies, Hotels, Super Markets, Temples, Departmental Stores, Institutions, Industrial Canteens and even Hospitals. The List is perpetual. The Clientele is being spread throughout India and even Foreign Countries for our exceptional accomplishment, which represent Magnitude of our Quality for which We indulge over the past two decades. Furthermore, We have patrons at many Countries, as our Machines are proficient in the United Arab Emirates, Sultanate of Oman, West Africa, South Africa, Sri Lanka, Myanmar, Malaysia, Singapore, Italy, Israel, Kuwait and The United States of America for over a period of 4 decade. Regarding our ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¢ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA SidvinÃA ÂA ÃA ÂA ÃA ÂA ÃA ¢ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¯ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¢ Machines, We wish to mention that for Hundred Percent Consumer Cleaning Efficiency, these are developed by Central Food Technological Research Institute, Mysore, ( A Council of Scientific and Industrial Research concern ) to clean 100 % adulterated materials in all Food Grains with fast, say a speed of 6 - 10 minutes per bag without wastage of main products and remove all adulterated alien extraneous such as stones, glass pieces and iron particles etc., grade them according to their commercial value and process further. We have pleasure to inform that We export our Machines to Foreign Countries through National Research and Development Corporation, New Delhi, under the Indian Technological Transfer Scheme of the Government of India. The process mainly involves the following procedure: ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¯ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¼ Removal of Impurity Lighter than the Products like Dust, Chaff, Stick etc., found in all Food grains. ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¯ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¼ Removal of Impurity Heavier than the Product like Stones, Glass Piece, Metal Pieces, Nails, Pins, etc., ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¯ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ÂA ÃA ¼ Removal of Equal Size or Volumetric Impurity than the Products. The Raw Material in your case, FOOD GRAINS is made to fall into the hopper of Sieving with Aspiration System which has been designed in such a way that the Product flows by gravity evenly and uniformly. All the lighter products such as Dust and Powder normally found in a consignment load of FOOD GRAINS is sucked and collected in the dust collection end. The Product is then made to pass through the vibratory deck which is so designed to reject all the heavier products and other impurities. On completion of the above major process, the yield is absolutely 100 % free from any Foreign Body or impurity. This is an added bonus to the large scale process. When the products is 100% impurity Free, it is staged for further process. Thanking you and inducing you of our best attention at all times. We remain,

Business Type

Exporter, Manufacturer, Distributor, Supplier, Fabricator, Producer

Employee Count

25

Establishment

1977

Working Days

Monday To Saturday

GST NO

29AAGCS3566E1Z5

Payment Mode

Cash Advance (CA)

Certification

ISO 9001

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29AAGCS3566E1Z5

Mysuru, Karnataka

C.E.O.

Mr Sidvin Ramesh Mysore

Address

17, Third Stage, Industrial Suburb, Vishweswara Nagar, Mysore South, Mysuru, Karnataka, 570008, India

food processing plant in Mysuru

Report incorrect details