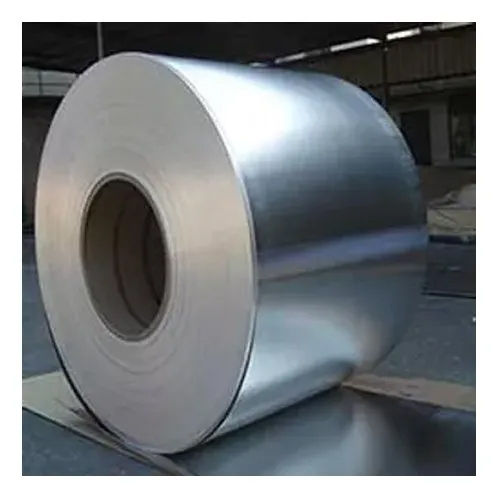

Aluminum Coils 3003 Application: Hvac

Price:

Get Latest Price

In Stock

Product Specifications

| Grade | 3003 |

| Coil Weight | 300 Kilograms (kg) |

| Application | HVAC, Condenser, Radiator, Evaporator, Heat Shield, Gutters, Downspouts, Roofing, and Siding. |

| Main Export Market(s) | Australia, Eastern Europe, Western Europe, Central America, Africa, Middle East, South America, Asia, North America |

| Main Domestic Market | All India |

Product Overview

Key Features

3003 aluminum coil is the most widely used aluminum alloy. It is made up of aluminum, copper, iron, manganese, silicon, and zinc. It is commonly used because it has great resistance to corrosion and is moderately strong. The 3003 aluminum coil is 20% stronger than 1100 grade alloys because it is fused with manganese.

Because ita s not heat treatable, it has to be strengthened using cold working alone.

The most common applications for the 3003 aluminum coil are for fuel tanks, sheet metal work and other types of projects that need a metal that is stronger than the 1100 series aluminum. In some cases, it is used for cooking utensils, refrigerator panels, gas lines, storage tanks, garage doors, buildera s hardware, and awning slats.

The machinability of the 3003 Aluminum is considered good for being an aluminum alloy. It is readily machined for the different applications. It can either be formed using conventional hot working or cold working. Ita s also possible to use conventional welding methods to shape 3003 aluminum. It is sometimes welded to other aluminum alloys, like 6061, 5052 and 6062, which should have an AL 4043 filler rod.

AL 3003 isna t heat treatable, but it can be forged with heat thata s between 500 and 950 degrees Fahrenheit. When using heat in this range, the aluminum can be hot worked easily. However, it is readily cold worked, which can be done using conventional methods. When annealing the alloy during or after using cold working techniques, it should be performed at 775 degrees Fahrenheit. This will give it enough time to thoroughly heat before being air-cooled. The only way to make this alloy hard is with the use of cold working. It can also be deep drawn, spun or brazed.

Company Details

Since our incorporation is in the year 1971, we, Maharashtra Metal (India) an ISO 9001:2008 Certified Company, are a recognized organization, engaged in manufacturing, supplying, importing, wholesaling, and exporting a commendable range of Ferrous and Non-Ferrous Metals. Our product range includes Aluminum Flat 6061, Aluminum Channel, Aluminum Diamond Tread Plate, Aluminum Channel, Aluminum Square 6061, Aluminium Hexagon, Aluminium Beam, Aluminium Pipe, Aluminium Plate, Aluminium Rod, Aluminium Square, Aluminium Square Tube, Aluminum Round 6061, Aluminum Tube SQR, Aluminum Tube Round, Aluminium Tread Plate, Aluminium Threaded Rod, Aluminium Sheet, Aluminium Tube Rectangular. Since its inception in Mumbai (Maharashtra), India, ours has been a Sole Proprietorship (Individual) firm. The products we offer are highly applauded in the market for their attributes like robust construction, dimensional accuracy, sturdy design, low maintenance, non-corrosive nature, high tensile strength, and compact design. Highly acknowledged for the features as mentioned above, our offered products find their applications in hydraulic, steel, engineering, pharmaceutical & medical, petrochemical, oil refineries, and chemical industries. Further, the metals offered by us can be customized based on size, dimensions, and specifications as per the requirements of our clients.

Business Type

Exporter, Importer, Supplier, Trading Company

Employee Count

20

Establishment

1971

Working Days

Monday To Saturday

GST NO

27ABQFM9720N1ZE

Payment Mode

Cash Advance (CA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ABQFM9720N1ZE

Mumbai, Maharashtra

Partner

Mr Girish Sanghvi

Members since

7 Years

Address

Shreepati Jewels, G Wing, G-8, Ground Floor, Opp Morar Baug, C. P. Tank, Mumbai - 400004, India Mumbai, Maharashtra, 400004, India

aluminium coil in Mumbai

Report incorrect details