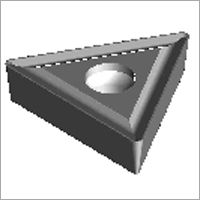

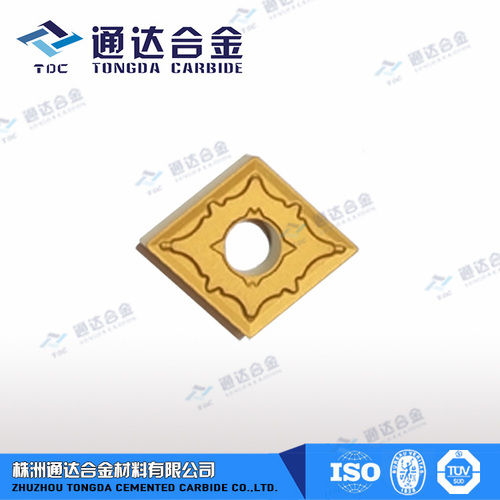

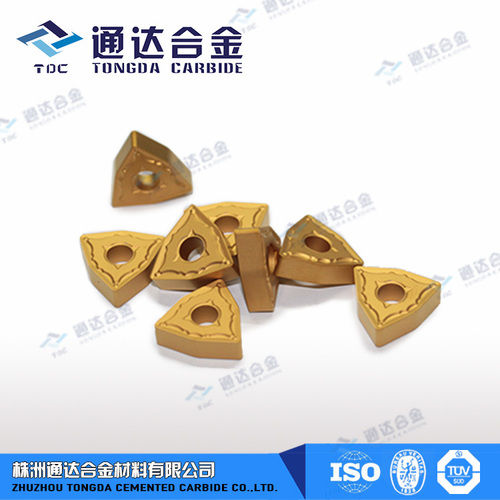

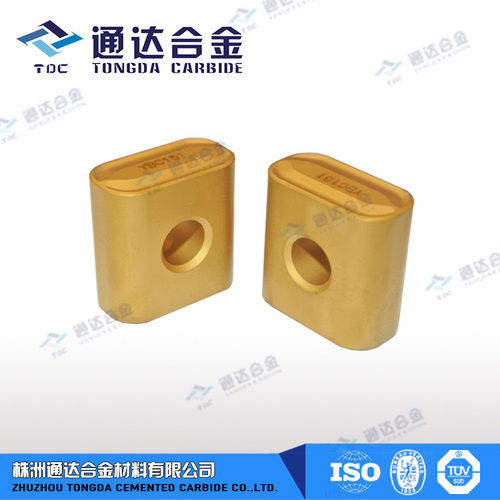

All Type Tungsten Carbide Inserts

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Tungsten Carbide |

| Hardness | High |

| Heat Resistance | High |

| Wear Resistance | High |

| Corrosion Resistance | Good |

| Applications | Industrial |

| Features | High Hardness, Wear Resistance, Heat Resistance, Sharp Cutting, Durable, Corrosion Resistance, Sturdiness |

Product Overview

Key Features

Carbide is more expensive per unit than other typical tool materials, and it is more brittle, making it susceptible to chipping and breaking. To offset these problems, the carbide cutting tip itself is often in the form of a small insert for a larger tipped tool whose shank is made of another material, usually carbon tool steel. This gives the benefit of using carbide at the cutting interface without the high cost and brittleness of making the entire tool out of carbide. Most modern face mills use carbide inserts, as well as many lathe tools and end mills. In recent decades, though, solid-carbide end mills have also become more commonly used, wherever the application's characteristics make the pros (such as shorter cycle times) outweigh the cons (mentioned above).

Our carbide cutting tools are widely known for its sturdiness,excellent working performance, longer functionality and well wear & corrosive resistance. These carbide cutting tools are in high demand in engineering industry and can be availed by our clients at market leading prices.

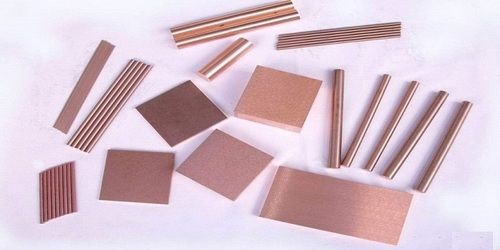

Tungsten Carbide blades are known for being sharp and durable. They are wear-resistant, and can be used in a variety of industrial applications where extremely sharp cutting instruments are needed. For example, carbide blades are well suited to cutting reflective materials for plotting and sign making. Although prone to chipping and breakage, when these pitfalls are avoided with the proper engineering, tungsten carbide blades can sustain significant industrial stresses.

Tungsten carbide is less brittle than other metals, and thus can withstand the rigors of constant use easily. At Specialty Blades, we manufacture carbide blades and tungsten carbide blades for a variety of industries. No matter what your application, chances are carbide blades are appropriate for you needs.

In fact, switching from blades made of other materials, such as titanium, carbon steel, and aluminum, to tungsten carbide blades may actually increase productivity. By handling tough jobs with ease, carbide blades can increase productivity by 10 or 20 percent in some industries. Some factories have found that although tungsten carbide is often more expensive, its durability and ability to withstand pressure makes the extra cost worth it.

At Specialty Blades, we are adept at crafting superior tungsten carbide blades as needed. Tungsten carbide can be treated with cobalt to produce certain characteristics. The more cobalt in the metal, the more shock resistant. While less cobalt will result in a more wear-resistant metal. Our application engineers are experienced at helping clients find the right blades for their needs.

Grade List for Carbide Cutting Tools

GradeDensity

g/cm3Hardness

HRAStrength

N/mm2 Min.ApplicationsISO grade

YG6X14.8-1591.7-931600High wear resistance and high strength; machining chilled cast iron and refractory steel, finishing of normal cast ironK10(ANSI C-2)

Company Details

Focusing on a customer-centric approach, Hubei FOTMA Machinery CO., LTD has a pan-India presence and caters to a huge consumer base throughout the country. Buy Tungsten Carbide in bulk from Hubei FOTMA Machinery CO., LTD at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

15

Establishment

1998

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Wuhan, Hubei

Pauline Zhou

Address

Guanggu Avenue 52#, Wuchang, Wuhan, Hubei, 430074, China

tungsten carbide tools in Wuhan

Report incorrect details