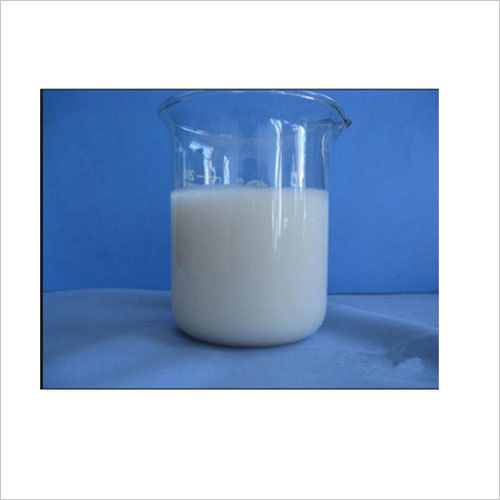

Kr Acrylic Polymer - Liquid Emulsion, Milky White Color | Waterproofing, Elastomeric Bonding, Superior Adhesion, Abrasion Resistant

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Milky white |

| Form | Liquid emulsion |

| Ambient Temperature | 0.50 C |

| Service Temperature | -40 to +90 C |

| Pot life | 30 minutes |

| Polymer Type | Acrylic copolymer |

| Application Method | Brush |

| Features | Excellent adhesion, Improves flexural, Waterproofing, Durable surface, Salt resistance, Carbonation resistance, High water pressure resistance, Self-curing |

Product Overview

Key Features

KR Acrylic Polymer mainly comprises of components based on salts of acrylic copolymer. When mixed with cement with several consistencies, the Polymer: Cement blend makes it apt to give the bonding as well as interrupt coating. KR Acrylic Polymer Protective waterproof slurry coating. The elastomeric and flexible nature of this system has properties that are able to fight the inadequacies of cement like tensile strength and low flexural strength, thin section fragility and low impact strength. The resultant system delivers a hard, tough wearing surface with abrasion, agent and weather carbonation resistance facilitated with excellent waterproofing effect for marine atmospheres as well.

PRODUCT SPECIFICATION / COMPLIANCES:

- Colour: Milky white.

- Form: Liquid emulsion.

- Abmt . Temp.: 0.50 C.

- Service Temp.: - 40o C to + 90o C.

- Pot life: Approx. 30 minutes.

PRIMARY APPLICATIONS:

Helps achieving waterproof underground structures. Waterproofing water retaining structures, terraces, parapets, bathrooms and sunken portions of toilet blocks. Bonding new concrete to old concrete. Fixing ceramic tiles, floor screeding and mosaic tiling. Crack repair and porous surface sealing. By using KR Acrylic Polymer the conditions created due to breeds of termites are avoided. Healthy conditions prevail and discomfort is eliminated.

PRODUCT FEATURES:

- Excellent adhesion to most building substrates.

- Improves flexural, tensile, and thin section fragility of cementations system.

- Allows breathing thus preventing peeling and scaling.

- Gives a tough, hardwearing surface with effective waterproofing.

- Reduces chloride / salt penetration in marine environment.

- Resists carbonation effect.

- Resists water pressures up to 5 bars.

- Self-curing, Increases overall structural durability.

Usage

Surface preparation of the substrate is vital for the effective adhesion and bonding of KR Acrylic Polymer . So, the surface should be free of laitance and loose dust particles, oil, grease and other loose dirt. The surface should be wire brushed and broomed before application. The performance of KR Acrylic Polymer whether patches, renders, screeds, toppings or slurry only, is dependent on the substrate preparation. Depending upon the structural condition, preparation should be done. The basic idea is that the substrate should be clean, sound and free from any deleterious material. The unevenness of the surface should be leveled. The corroded reinforcement should also be made clean and all loose particles should be removed.

Barrier coat Prepare a slurry coat of cement- KR Acrylic Polymer mixing them at a ratio 1:1.5. The slurry has to be applied on the repaired surface with a soft 4-inch plastic thistle brush in one direction. Allow this first coat to air dry for about 4 hrs. Do not spray any water on it. Apply a second coat of the slurry in the direction of right angles to the first coat. Allow this coat to air dry overnight, and do not spray any water or walk over the surface. After about 12 hours of air drying of the second coat, sprinkle little water on the coating at an interval of 2 hours. Continue this for 48 hours. The surface can then be put to use. We suggest conducting a pond test in order to ascertain the Effectiveness of KR Acrylic Polymer. In case of improper waterproofing at a particular spot, a touch up coat of the KR Acrylic Polymer and Cement mixture should be applied over the particular area and must be allowed to cure.

For other repair applications, please refer to Repair System guideline. KRWP technical service team is also available to train your personnel and supervise the initial operation at your construction site.

PACKAGING: 5/10/30/50 / 100 kg HDPE. Containers.

SHELF LIFE : 12 months in un opened container.

STORAGE: Keep away from direct sunlight and extreme heat.

COVERAGE: 1 Kg of KR Acrylic Polymer approximately gives average coverage of ~30 square feet as a slurry coating after mixing with cement.

TECHNICAL SERVICE:

KRWP has established itself in various fields on the basis of its dependable technical service. For this purpose, we maintain a well equipped laboratory for research & quality assurance of all products. Our experienced personnel are always on call and would always be available for product demonstrations and product performance monitoring.

SAFETY PRECAUTIONS:

KR Acrylic Polymer is non toxic and non-flammable. However, any splashes on the human body must be washed with plenty of water.

Company Details

Focusing on a customer-centric approach, K. R. WATERPROOFINGS & POLYMERS has a pan-India presence and caters to a huge consumer base throughout the country. Get Construction Chemicals from K. R. WATERPROOFINGS & POLYMERS at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

19

Establishment

2012

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Thane, Maharashtra

Proprietor

Mr. Krishna Rama Mestry

Address

Shiv Kailash Chs Ltd, Gr. Floor, Flat No 01, Yashodhan Nagar, Thane, Maharashtra, 400606, India

acrylic polymer in Thane

Report incorrect details