- Tradeindia

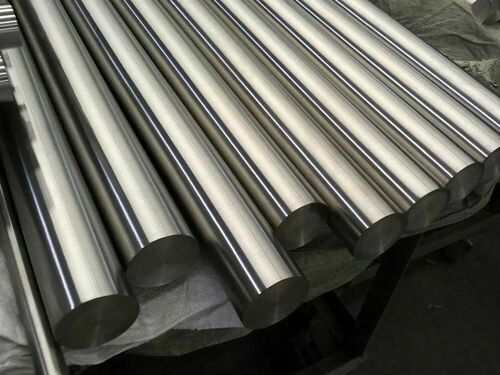

- Bright Bars

- Nickel Bars

Nickel Bars

(118 products)Nickel Bars - Application: Construction

Price: 160 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product NameOther, Nickel Bars

Steel TypeStainless Steel

GradeIndustrial

ShapeBar

SurfacePolished

Niko Steel And Engineering Llp

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller23 Years

View More

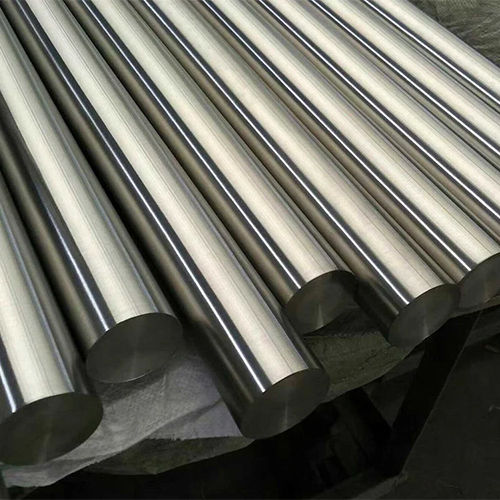

Nickel Alloy Round Bars - High Strength 0.5 Inch Diameter, Corrosion Resistant and Lightweight

Price Trend : 160.00 - 190.00 INR

Nickel Flat Bar - Application: Construction

Price: 120 INR/Piece

MOQ10 Piece/Pieces

Product TypeNickel

ShapePlate

HardnessYes

GradeIndustrial

ApplicationConstruction

ColorSilver

Copper Nickel Alloy Round Bar - Application: Construction

Price: 1120 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

ShapeBar

ResistanceCorrosion Resistance

Chemical CompositionCuNi10Fe1Mn

ApplicationConstruction

View More

Nickel Chromium Alloy Bar - Application: Casting

Price : 700 INR

Nickel Chromium Alloy Bar - Application: Casting

Price : 700 INR

Nickel Busbar - Pure Nickel, Hard Stripe Design | Silver Finish for Construction Applications

Price: 2000 INR/Kilograms

MOQ10 Kilograms/Kilograms

ColorSilver

Product TypeNickel

ShapeStripe

HardnessHard

GradePure Nickel

ApplicationConstruction

Cupro Nickel Flat Bars - 1200x2000 Millimeter Size, Nickel Material, Perfect for Versatile Applications

Price: 658 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeMetal

MaterialNickel

ShapeSheet

ApplicationConstruction

Dimension (L*W*H)1200 x 2000 Millimeter (mm)

View More

200-201 Nickel Alloy Round Bars - Application: Casting

Price : 658 INR

Nickel C276 Hastelloy Flat Bars

Price : 658 INR

Hastelloy Round Bars - Material: Nickel

Price : 658 INR

C22 Hastelloy Flat Bars - Material: Nickel

Price : 658 INR

90-10 Cupro Nickel Bars - 50000 psi Strength, Hardness 70-120, Durable Nickel Material in Sheet Shape

Price : 658 INR

70-30 Cupro Nickel Round Bars - Application: Steel Making

Price : 658 INR

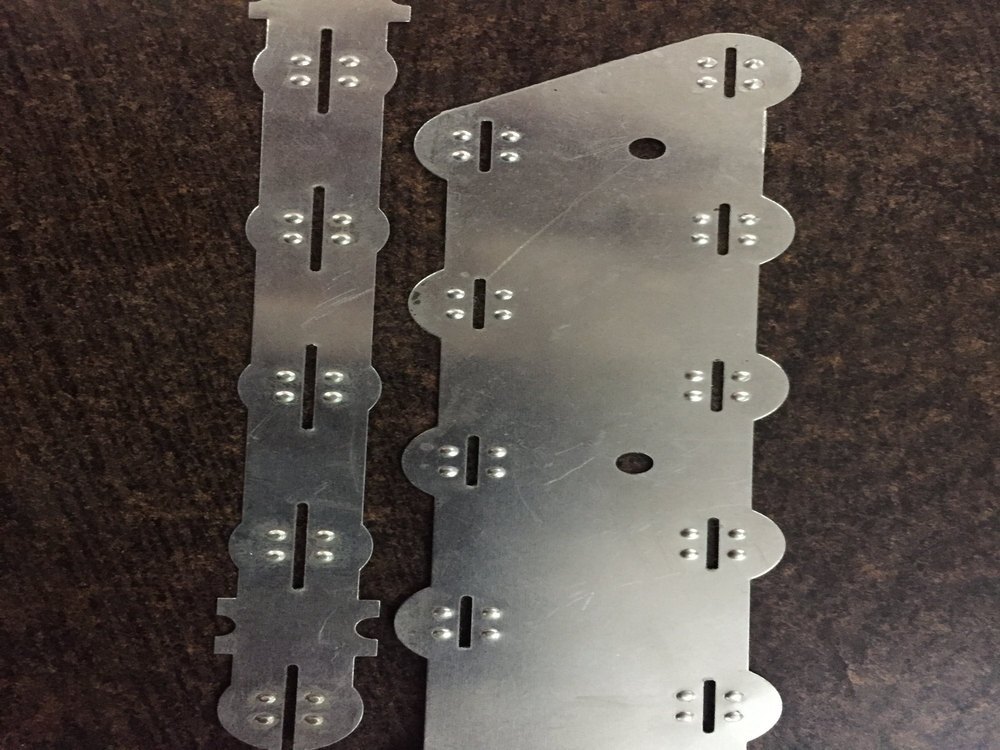

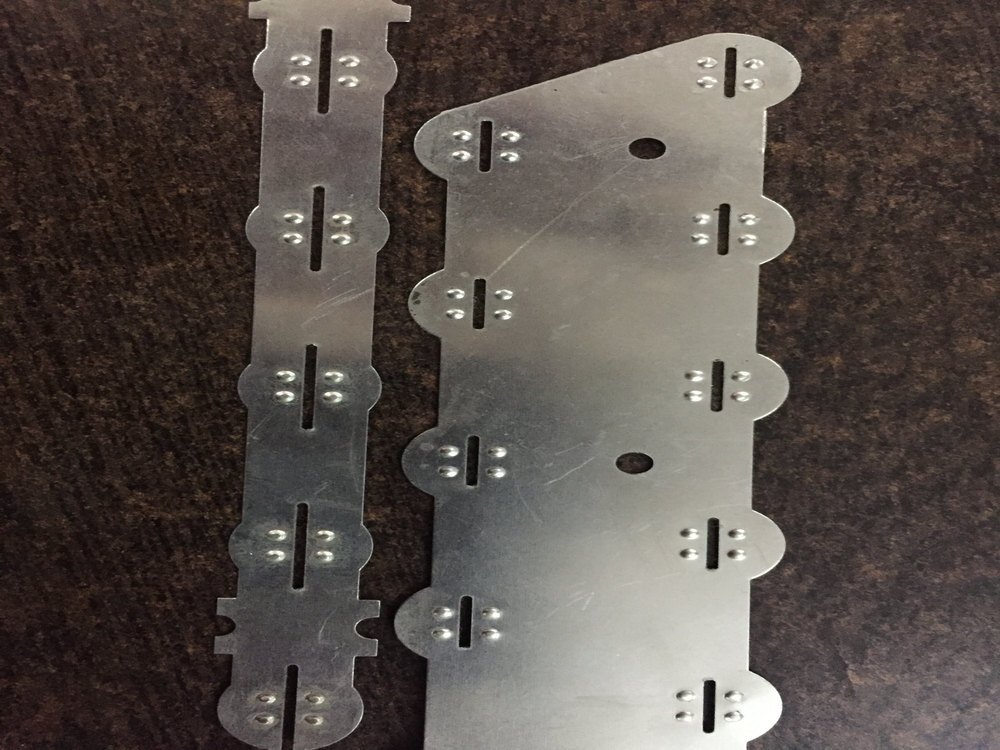

Nickel Busbar - Fuse Type (Fusible) with Cell Level Fusing, 0.10-0.50mm Thickness, High Strength Silver Plate

Price: 2500.0 INR/Kilograms

MOQ1 Kilograms/Kilograms

ColorSilver

Product TypeNickel

ShapePlate

StrengthHigh

HardnessRigid

ResistanceCorrosion resistance

View More

Nickel 200 Round Bar - Application: Construction

Price : 2500 INR

Nickel 201 Round Bar - Application: Construction

Price : 2500 INR

Uns N02200 Nickel 200 Round Bar - Application: Industrial

Price : 5000 INR

Nickel And Nickel Alloy Bar Application: Construction

Price: 1100 INR/Piece

MOQ50 Piece/Pieces

ColorSliver

Product NameSteel Components

Steel TypeStainless Steel

Steel Product TypeSteel Pipes

ShapeBar

ApplicationConstruction

Nickel Bar By Pawan Steel

GradeNickel 200/201

Product TypeOther, Metal Bar

MaterialOther, Nickel

ShapeBar

Chemical CompositionNickel

Density8.90 Gram per cubic centimeter(g/cm3)

200 Nickel Bars Application: Construction

MOQ100 Kilograms/Kilograms

Product NameSteel Products

Thickness50 mm to 6000 Millimeter (mm)

Steel StandardOther, ASTM B160 / ASTM SB160

SurfacePolished

ApplicationConstruction

ColorSilver

Metcore Steel & Alloys

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Cupro Nickel 90-10 Flat Bars - High-Grade Polished Copper Finish | Durable, Corrosion-Resistant, AISI Standard Steel Bars

MOQ10 Piece/Pieces

Steel Product TypeSteel Bars

GradeHigh

ShapeBar

Steel StandardAISI

SurfacePolished

ApplicationConstruction

Nickel Bar

MaterialNickel

GradeN4, N5, N6, N7, N02200, N02201

Diameter Range (mm)0.8-500

Tolerance (mm)+/-0.03 to +/-2.0

ProcessHot forging, rolling

StandardsGB4435-84, ASTM B160-93, DIN17740

Nickel Alloy Round Bar - Finish: Polished

Price: 2500 INR/Kilograms

MOQ100 Kilograms/Kilograms

Specific UseIndustrial

GradeEN41B

FinishPolished

Top Rated Products

FAQs Related to Nickel Bars

Who are the top nickel bars manufacturers in India?

- Niko Steel And Engineering Llp

- Metalic Corporation India

- Steel Mart

- Baoji Hong Ya Da Nonferrous Metal Materials Co., Ltd.

- Nandishwar Steel

- Pawan Steel

- Dhruva Superalloys

- Technolloy Inc.

- Aurico Alloys Llp

- Jagdish Metals And Alloys

Which cities have the largest number of nickel bars suppliers?

- Mumbai

- Chennai

- Kolkata

- Pune

- Delhi

- Ahmedabad

- Ludhiana

- Vadodara

- Raipur

- Jamnagar

- Shanghai

- Baoji

- Xian

- Nanjing

- Suzhou

What is the price range for nickel bars offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Alloyed Steel India | INR | Nickel Alloy Round Bar | 800 |

| AMANAT STEELS PVT. LTD. | INR | Nickel Round Bar | 1820 |

How many trusted sellers are available for nickel bars?

- NIKO STEEL AND ENGINEERING LLP

- STEEL MART

- Metal Tech Overseas

- Technolloy Inc.

- AURICO ALLOYS LLP

- JAGDISH METALS AND ALLOYS

- PAWAN STEEL

- METCORE STEEL & ALLOYS

- Dinkar Alloys

- N D Metal Impex

- VIRAMI STEEL HUB

- DHRUVA SUPERALLOYS

- SHINE METAL AND ALLOYS

What is the minimum order quantity for nickel bars?

Do listed companies have registration & certifications?

- NANDISHWAR STEEL

- BAOJI HONG YA DA NONFERROUS METAL MATERIALS CO., LTD.

- NIKUNJ STEEL CENTRE

- SHINE METAL AND ALLOYS

- Xi'an GangYan Special Alloy Co.Ltd.

- REGENT STEEL & ENGG. CO.

What is the get latest price feature?

What types of payment methods are accepted by the nickel bars suppliers?

Nickel Metal Plate - Application: Construction

Price: 1550.00 INR/Unit

MOQ10 Kilograms/Kilograms

ColorGrey

Product TypeNickel

ShapePlate

Elongation35 %

HardnessYes

GradeA

Nickel Steel Round Bar - Inconel 600 to 925 Grades, Cold Drawn or Belt Polished, Gray Color

Price: 250.0 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorGray

Steel TypeOther, Nickel Steel

Steel Product TypeSteel Bars

GradeINCONEL 600, 601, 625, 718, 800, 800H, 800HT,825, 925. SMO 254, ALLOY 20(20CB3), MONEL 400, 500K, RA 330, HASTELLOY C-276, HASTELLOY B2, B3, TITANIUM Gr 1 to 5

SurfaceCold drawn or Belt polished condition

ApplicationConstruction

Nickel Alloy Round Bar - Diameter 6-50mm, Length 1000-6000mm | Polished Surface, 600MPa Tensile Strength, 450MPa Yield Strength, Aerospace & Chemical Use

MaterialNickel Alloy

Diameter6-50mm

Length1000-6000mm

Surface FinishPolished

Tensile Strength600MPa

Yield Strength450MPa

Dhruva Superalloys

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

Nickel Lumps

Payment TermsCash Against Delivery (CAD), Cheque

Main Domestic MarketAll India

Nickel Bar - High-Quality Nickel Alloy, Durable Performance and Corrosion Resistance

MaterialNickel

FormRound

DiameterVariable

LengthVariable

FinishSmooth

ToleranceStandard

Nitronic 50 Round Bar Grade: Multigrade

Price: 2500 INR/Kilograms

MOQ40 Kilograms/Kilograms

GradeMultigrade

MaterialALLOY, Other

SizeCustomized

WarrantyYes

View More

Inconel 600 Round Bar - Nickel Alloy , High Strength and High Resistance, Multigrade Durability

Price : 2000 INR

Inconel Round Bar - Nickel-Chromium Alloy, High Strength & Corrosion Resistance for Industrial Applications

Price : 2000 INR

High Nickel Alloys Round Bar - Alloy Steel, Polished Silver Finish | Superior Strength for Structural and Decorative Applications

Price: 1000 INR/Kilograms

MOQ100 Kilograms/Kilograms

ColorSilver

Product NameSteel

Steel TypeAlloy Steel

Steel Product TypeSteel Bars

ShapeBar

SurfacePolished

Invar 36 Nilo 36 Low Expansion Alloy - Iron-Nickel Alloy, Silver, Density 8.10 g/m³, Elongation 9%, Hardness 160, Melting Range 1427°C, Strength 850 MPa

Price: 22 USD ($)/Kilograms

MOQ1000 Kilograms/Kilograms

Product TypeNickel Alloy

ShapeBar, Square

Elongation9

Strength850MPa

Hardness160

Resistance0.49

Nickel 201 Round Bar Application: Manufacturing

Price: 3750 INR/Kilograms

MOQ2 Kilograms/Kilograms

MaterialNickel 201 Round Bar

GradeNickel 201 Round Bar

LengthAs Per Standard Millimeter (mm)

TypeRound Bar

ApplicationManufacturing

FinishBright / Black

Nickel Alloy Round Bar - Various Sizes, Polished Outer Finish, Abrasion Resistance, Thermal Conductivity

Price: 800 INR/Kilograms

MOQ100 Kilograms/Kilograms

TypeRound Bars

Surface TreatmentPowder Coated

ShapeRound

ColorGolden

ApplicationIndustrial

MaterialNickel Alloy

Nickel 200 Round Bars - High Grade Nickel, Various Thickness & Dimensions | Durable, Sturdy, Smooth Surface

MaterialNickel 200

ShapeRound

Diameter Range6-100mm

Length Range1000-6000mm

Surface FinishSmooth

Tensile Strength500 MPa

Nickel Round Bars

Price: 2499.00 INR/Kilograms

MOQ1 Kilograms/Kilograms, Kilogram, Kilogram

TechniqueHot Rolled

MaterialNickel

Length6 Meter (m)

ApplicationConstruction

TypeNickel Round Bars

View More

Monel Round Bar - Nickel-Copper Alloy, Various Diameters , Customizable Lengths , Mill Finish , Annealed Condition , ASTM B163 Standards

Price : 1100 INR

Nickel Alloy Round Bar - Various Diameters, Customizable Lengths | Polished Surface Finish, ASTM & ASME Standards, ±0.005" Tolerance

Price : 1100 INR

Nickel 200- 201 Round Bar

Price : 1100 INR

Nickel Alloy Round Bar Diameter: 1Mm-300Mm Millimeter (Mm)

Price: 1500 INR/Kilograms

MOQ1 Kilograms/Kilograms

Diameter1mm-300mm Millimeter (mm)

StandardASTM

MaterialNickel Alloy

TypeRound Bar

Grade200, 201

Length5-6 Meter (m)

White Nickel Alloy Bars

MaterialNickel Alloy

Diameter6-50mm

Length1000-6000mm

Surface FinishPolished

Tensile Strength800 MPa

Yield Strength600 MPa

Silver Nimonic 75 Round Bar

Price: 1800 INR/Kilograms

MOQ20 Kilograms/Kilograms

Product TypeMetal Products

SizeCustomized

ColorSilver

View More

Nickel 200 Round Bar

Price : 1200 INR

Alloy A286 Bar Chemical Composition: A-286

Price: 1850 INR/Kilograms

MOQ1 Kilograms/Kilograms

HardnessAs Per Standard

StrengthAs Per Standard

PurityAs Per Grade

Product TypeAlloy

MaterialA286

AlloyNickel Alloy A286

Latest from Nickel Bars

200 Nickel Bars

By:

Metcore Steel & Alloys

Pure Quality Nickel Bars

By:

Vandana Impex

Nickel Alloy 201 Round Bar

By:

Jaiman Metalloys Llp

Copper Nickel Bars

By:

Kamal Metal Corporation

Nickel Round Bar

By:

Kamlesh Impex

Nickel Alloy Round Bars

By:

Chemtech Alloys Pvt. Ltd.

Popular Nickel Bars

Nickel Bars

Nickel bars are a solid form of metal mainly composed of nickel element, which highly resists corrosion, with excellent strength and durable nature. Industries such as electronics, chemical, aerospace, marine, automotive, hardware manufacturing, etc., extensively source nickel bars. This metal facilitates various applications including manufacturing components of various industrial-grade equipment like turbines, heat exchangers, batteries, and machinery. Moreover, highly versatile stainless steel and other alloys are also produced with nickel as the main composition.

Applications of Nickel Bars

-

Aerospace Industry

Nickel bars are used to manufacture turbine blades, engine components, and other high-temperature, high-stress parts due to their excellent heat and corrosion resistance.

-

Marine Industry

In the marine sector, nickel bars are utilized for making ship parts, underwater pipelines, and desalination equipment, owing to their ability to withstand harsh seawater environments.

-

Chemical Processing

Nickel bars are essential in chemical processing plants for constructing reactors, heat exchangers, and storage tanks, as they can resist corrosion from various chemicals and high temperatures.

-

Electronics

Nickel bars are used in the electronics industry for making components such as connectors, batteries, and electromagnetic shielding, benefiting from nickel's conductive and corrosion-resistant properties.

-

Oil and Gas

In the oil and gas industry, nickel bars are used in drilling equipment, pipelines, and processing units, where they endure extreme temperatures and corrosive substances.

-

Automotive Industry

Nickel bars are employed in the automotive industry for making exhaust systems, catalytic converters, and battery components, enhancing durability and performance.

-

Medical Field

Nickel is biocompatible and has high corrosion and wear-resistant properties due to which it is extensively sourced in the medical field for producing surgical instruments including medical implants, surgery tools, etc.

Benefits of Nickel Bars

-

High Corrosion Resistance

Nickel bars have high corrosion resistance and are employed for producing stainless steel, because of which it has extreme strength, durability, and long lifespan. Nickel is used to make various alloys for manufacturing mechanical components suitable for working in harsh environments like chemical processing plants and marine.

-

Exceptional Strength and Durability

Nickel components have high strength and durability because of which they can work for long hours with wear and tear. Even under extreme conditions they boast high performance and efficiency, increasing overall productivity.

-

High-Temperature Resistance

Components manufactured using Nickel bars have high-temperature resistance, due to which they can withstand extremely high temperatures. This makes this element compatible to be used in industries like aerospace, automotive, and energy sectors.

-

Versatility

No doubt that nickel bars are highly versatile, having the potential to be shaped in any mechanical component used widely across industries like medical, electronics, manufacturing facilities, workshops, etc. Moreover, a diverse range of machinery and construction material is developed with stainless steel, made from nickel.

-

Good Conductivity

Nickel is a great conductor of heat and electricity. In the electrical industry, they are sourced extensively for manufacturing components like batteries, heat exchangers, etc.

Is Nickel Stronger Than Steel?

Element Nickel alone is generally not stronger than steel when it comes to tensile strength and toughness, but its alloys including high-grade steels like high-carbon and stainless steel are. These metals have higher tensile strength and hardness as compared to fine nickel. Comparatively, the tensile strength of stainless steel is around 600-800 MPa, and pure nickel has around 370 MPa.

-

Unique Advantages of Nickel

Nickel offers some unique advantages including high corrosion and oxidation resistance making it compatible to be used in chemically exposed and harsh environments. Select Nickel alloys including Inconel or Monel have the ability to sustain their tensile strength even at extremely high temperatures, which is very beneficial for aerospace and energy sector applications. Moreover, nickel’s ductility makes it convenient to bend and shape it in various forms without cracks.

-

Steel's Unique Advantages

Steel is valued for its versatility, with a wide range of grades tailored to different applications, from construction to automotive industries. It is generally more cost-effective than nickel and its alloys, making it the preferred choice for many structural applications. Alloy steels offer a high strength-to-weight ratio, ideal for construction and manufacturing.

In conclusion, while steel is typically stronger than nickel, the choice between them depends on specific application requirements, such as the need for corrosion resistance or high strength.

Major Types of Nickel Bars Used Across Industries

-

Pure Nickel Bars

Pure nickel bars, typically composed of over 99% nickel, offer excellent corrosion resistance and high thermal and electrical conductivity. They are used in chemical processing, electronics, and aerospace industries.

-

Nickel Alloy Bars

Nickel alloy bars are made by combining nickel with other metals to enhance their properties. Common nickel alloys include:

- Inconel: Known for high-temperature strength and oxidation resistance, used in aerospace and gas turbines.

- Monel: Offers excellent corrosion resistance, especially in marine and chemical environments, used in valves and pumps.

- Hastelloy: Highly resistant to corrosion and oxidation, ideal for chemical processing and high-temperature applications.

-

Nickel-Copper Bars

Nickel-copper alloys, such as Monel, combine the strength and corrosion resistance of nickel with the enhanced mechanical properties of copper. They are commonly used in marine and chemical industries due to their resistance to seawater and acids.

-

Nickel-Chromium Bars

Nickel-chromium alloys, like Inconel, are known for their high-temperature resistance and strength. They are used in applications requiring durability and stability at elevated temperatures, such as jet engines and industrial furnaces.

-

Nickel-Iron Bars

Nickel-iron alloys, such as Invar, have a low coefficient of thermal expansion, making them suitable for precision instruments, clocks, and scientific equipment.

-

Nickel-Molybdenum Bars

Nickel-molybdenum alloys, such as Hastelloy, offer superior resistance to reducing environments and high temperatures. They are used in chemical processing, petrochemical, and nuclear industries.

Nickel Bars Price List

Product Name | Expected Price |

|---|---|

| Nickel Alloy Round Bar | 800 |

| Nickel Round Bar | 1820 |

This Data was Last Updated on 2025-09-06

Nickel Bars Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 23 Years |

Metalic Corporation India Kolkata, India | 21 Years |

Steel Mart Mumbai, India | 19 Years |

Baoji Hong Ya Da Nonferrous Metal Materials Co., Ltd. Baoji, China | 11 Years |

Nandishwar Steel Mumbai, India | 6 Years |

Pawan Steel Mumbai, India | 6 Years |

Dhruva Superalloys Mumbai, India | 5 Years |

Technolloy Inc. Mumbai, India | 3 Years |

Aurico Alloys Llp Mumbai, India | 2 Years |

Jagdish Metals And Alloys Mumbai, India | 2 Years |

Upcoming Tradeshows

ENGIMACH 2025

Wed, 03 Dec, 2025 - Sun, 07 Dec, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

8th INTERNATIONAL SOAP & DETERGENT EXPO 2026

Thu, 26 Feb, 2026 - Fri, 27 Feb, 2026

YARNEX - Mumbai 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

Spectra Expo 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INDIA GREEN ENERGY EXPO 2026

Wed, 29 Jul, 2026 - Fri, 31 Jul, 2026

Indian Ceramics Asia 2026

Wed, 28 Jan, 2026 - Fri, 30 Jan, 2026

PharmaTech Expo & LabTech Expo 2026

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Pune Expo 2025

Wed, 10 Dec, 2025 - Fri, 12 Dec, 2025

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories